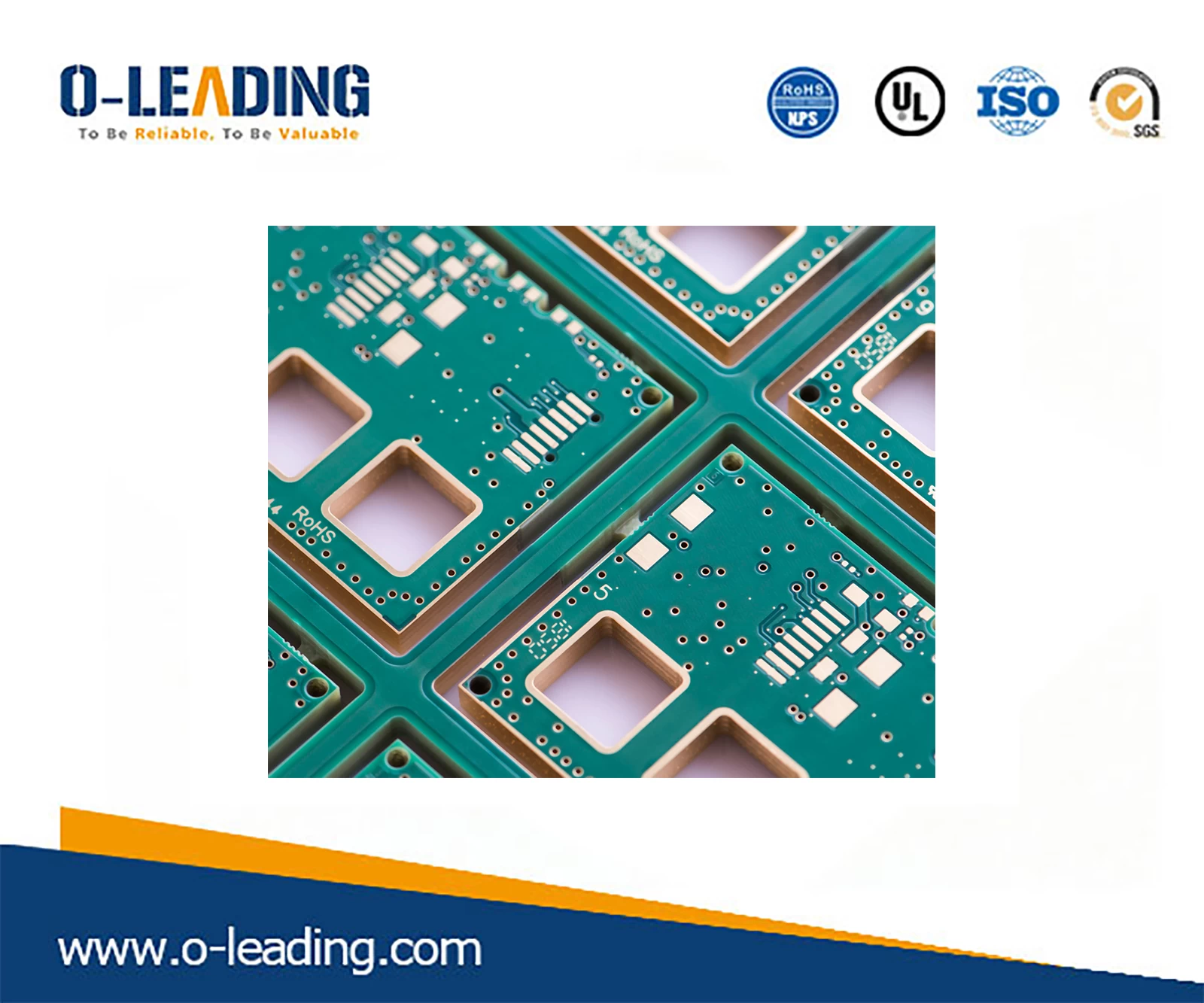

SMT defect analysis and countermeasures

A common cause of overlap between leads is that the spacing between the end connectors (or pads or wires) is not large enough. In reflow soldering, the overlap may be caused by excessive solder paste thickness or excessive alloy content. Another reason is that the solder paste collapses or the solder paste viscosity is too small.

In wave soldering, the overlap may be related to the design, such as slow transfer speed, improper shape of the solder wave, or improper amount of oil in the solder wave, or insufficient flux. The specific gravity of the flux and the preheating temperature also have an effect on the lap joint. Projects and countermeasures that should be detected when the bridge appears. PCB board.

Test item 1: Whether there is a gap between the printing screen and the substrate.

Countermeasures:

1. Check whether the substrate has deflection. If there is deflection, install an anti-deformation mechanism in the reflow oven;

2. Checking the substrate holding structure of the printing machine so that the holding state of the substrate is consistent with the original plane;

3. Adjust the parallelism between the screen and the working surface of the PCB board.

Test item 2: Whether there is tilt (non-parallel) of the scraper working surface corresponding to the screen layout.

Countermeasure: Adjust the parallelism of the scraper.

Test item 3: Whether the working speed of the scraper is overspeed.

Countermeasure: Repeat the adjustment of the blade speed (the transfer of the solder paste when the blade speed is too fast will reduce the viscosity of the solder paste and perform the release before the solder paste restores the original viscosity, which will result in poor solder paste collapse).

Test item 4: Whether the solder paste is returned to the reverse side of the screen.

Countermeasures:

1. Whether the design of the screen opening is slightly smaller than the substrate soldering area;

2. There must be no gap between the screen and the substrate;

3. Does it over-emphasize the use of solder paste for micro-gap assembly? Micro-gap assembly often selects a small-sized solder paste. If it is not necessary, the solder paste can be replaced.

Test item 5: Is the printing pressure too high, and whether there is a scraper cutting into the opening of the stencil. Line Card factory china.

Countermeasures:

1. The hardness of the working part of the polyester scraper should be moderate, too soft and easy to produce poor cutting into the opening of the screen;

2. Readjust the printing pressure.

Test item 6: Whether the printing conditions of the printing press are appropriate.

Countermeasure: Detect the working angle of the scraper and use a 60 degree angle as much as possible.

Test item 7: Whether the amount of solder paste supplied is appropriate.

Countermeasure: The amount of solder paste supplied to the press can be adjusted.