Technical characteristics of SMT process and common defects and solutions in dispensing process

Features of SMT process technology:

The characteristics of SMT process technology can be compared with the traditional through hole insertion technology (THT). From the perspective of assembly process technology, the fundamental difference between SMT and THT is "stick" and "plug". The difference between the two is also reflected in the substrate, components, component form, solder joint morphology and assembly process methods.

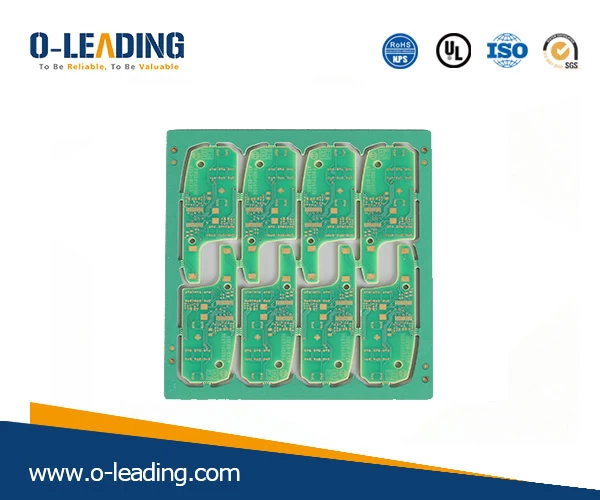

Halogen free pcb factory china

Common defects and solutions in SMT dispensing process

1, component shift

1) The phenomenon is that the component is displaced after the patch adhesive is cured. In serious cases, the component pins are not on the pad. The reason is that the glue of the patch glue is not uniform, for example, the two components of the chip component are more than one; When the patch is displaced, the initial adhesive force of the patch glue is low; after the dispensing, the PCB is placed for too long and the glue is semi-cured.

Solution: Check if the nozzle is blocked, remove the unevenness of the glue; adjust the working state of the placement machine; change the glue; the PCB placement time after dispensing should not be too long (less than 4h)

2, after the wave soldering will fall off

1) The phenomenon is that the bonding strength of the component after curing is not enough, lower than the specified value, sometimes it will fall off when touched by hand. The reason is because the curing process parameters are not in place, especially the temperature is not enough, the component size is too large, the heat absorption Large; light curing lamp aging; insufficient amount of glue; component / PCB pollution.

Solution: adjust the curing curve, especially to improve the curing temperature. Usually, the peak curing temperature of the heat curing adhesive is about 150 °C. If the peak temperature is not reached, it will cause the film to fall off. For the light curing glue, it should be observed whether the curing light is aging. Whether the lamp is black or not; the amount of glue and the contamination of the component/PCB are issues that should be considered.

3. After the curing, the component pins are floating/displaced.

1) The phenomenon of this fault is that the component leads float or shift after curing. After the wave soldering, the tin material will enter the pad. In severe cases, short circuit and open circuit will occur. The main cause is uneven patch and patch. Excessive amount of glue or component offset when patching.

Solution: adjust the dispensing process parameters; control the amount of dispensing; adjust the processing parameters of the patch.