What is a high Tg circuit board? The advantages of using high Tg PCB?

The difference between different material PCB boards

The PCB boards are divided according to the grade level from bottom to high as follows:94HB - 94VO - 22F - CEM-1 - CEM-3 - FR-4

94HB: ordinary cardboard, not fireproof (the lowest grade material, die punching, can not be used as power supply board)

94V0: Flame Retardant Cardboard (Die Punching)

22F: Single-sided semi-glass fiber board (die punching)

CEM-1: Single-sided fiberglass board (computer drilling is necessary, not die punching)

CEM-3: Double-sided semi-glass fiber board (except for double-sided cardboard, it is the lowest-end material of double-sided board. Simple double-sided board can use this material, which is 5~10 yuan/square meter cheaper than FR-4)

FR-4: Double-sided fiberglass board

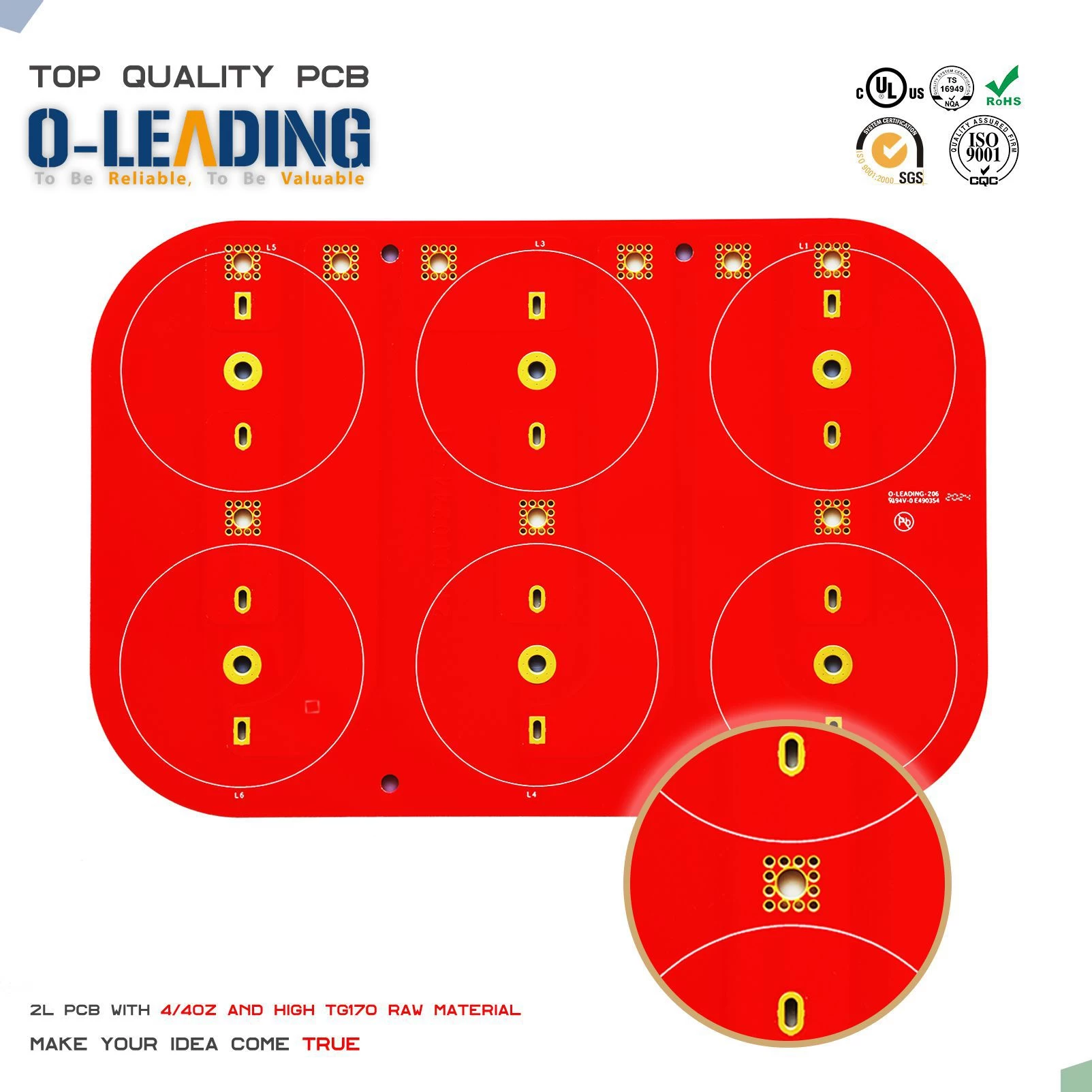

China OEM fast delivery 1 to 12 layers hasl FR4 electronic

What are the advantages of high Tg PCB and the advantages of using high Tg PCB?

When the temperature of a high Tg printed board rises to a certain area, the substrate will change from "glassy" to "rubbery". The temperature at this time is called the glass transition temperature (Tg) of the board. Tg means that the substrate remains rigid The highest temperature.

That is to say, ordinary PCB substrate materials will not only soften, deform, and melt at high temperatures, but also exhibit a sharp decline in mechanical and electrical properties.

Generally, the plate with Tg is more than 130 degrees, the high Tg is generally more than 170 degrees, and the medium Tg is more than 150 degrees. Usually PCB printed boards with Tg ≥ 170°C are called high Tg printed boards.

High Tg refers to high heat resistance. As the Tg of the substrate is increased, the heat resistance, moisture resistance, chemical resistance, and stability of the printed board will be improved and improved. The higher the TG value, the better the temperature resistance of the plate, especially in the lead-free process, where high Tg applications are more common. With the rapid development of the electronic industry, especially the electronic products represented by computers, the development of high functionality and high multilayers requires higher heat resistance of PCB substrate materials as an important guarantee. The emergence and development of high-density mounting technologies represented by SMT and CMT have made PCBs more and more inseparable from the support of high heat resistance of substrates in terms of small aperture, fine circuit and thinning.

Therefore, the difference between the general FR-4 and the high Tg FR-4 is the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, and thermal decomposition of the material in the hot state, especially when heated after moisture absorption. There are differences in various conditions such as thermal expansion. High Tg products are obviously better than ordinary PCB substrate materials.