"Three Inspections" and "Three Nos" in PCB Quality Management

In order to ensure that the quality of the PCB can accomplish these three principles, first of all, three inspections are required.Three inspections: self-inspection, mutual inspection, special inspection

What is the three-inspection system is an inspection system that combines the self-inspection of operators, the mutual inspection between operators and the special inspection by full-time inspectors.

1 Start with purchasing

Establish a strict raw material inspection system and work method, and do not accept defective products.

2 Produced according to technical standards and process requirements

The technical department must put forward technical standards and process requirements, as well as related drawings before production, and organize all staff to learn. Technical standards that only technicians know are meaningless standards. The wrong drawing is the most terrible bad product.

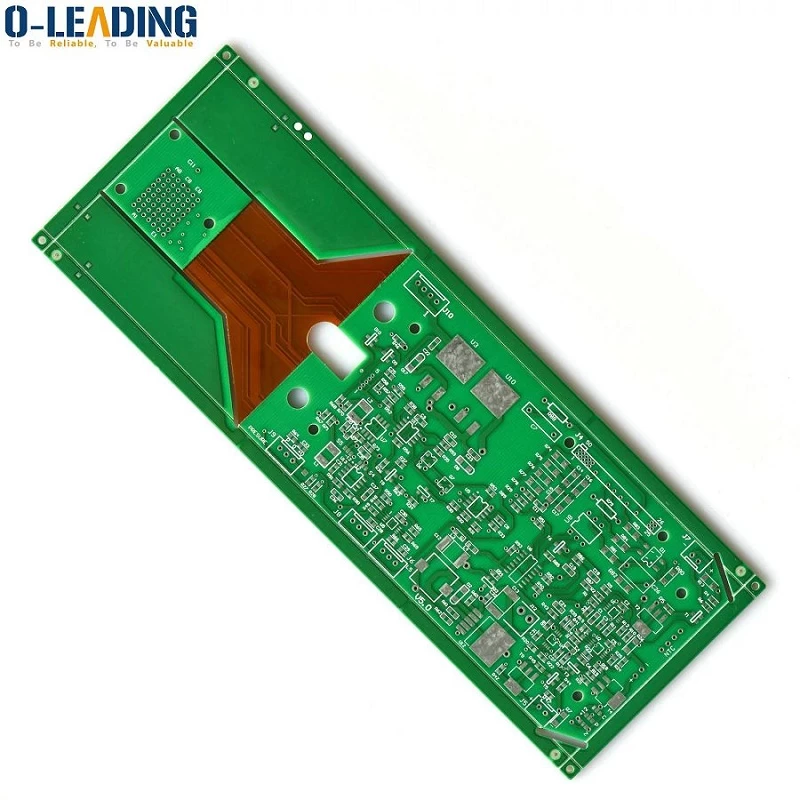

Chian Laser Printer Automotive Pcb Laptop Battery Pcb Boards supplier

3 Implementation of product inspection support standards

It means that good products are produced, not tested. However, for piece count management and quota management, without quality inspection management in the production process, quality standards cannot be effectively guaranteed. Irresponsible inspectors are the main cause of the defective product flow.

4 Mutual inspection of production processes

The previous responsible process is responsible for the next responsible process——

Does not produce defective products. The next responsible process supervises the previous process-no defective products are accepted.

5 Final packaging inspection:

No defective products are shipped from the factory. If the bad products are shipped to the factory for temporary benefit, it is actually hitting the job of the enterprise.

Three non-principles: do not accept defective products, do not manufacture defective products, and do not flow out defective products.

The basic requirements are:

1Do not accept unqualified products

Non-acceptance of unqualified products means that before production and processing, employees first check the conformity of the products passed before according to the regulations. Once a problem is found, they have the right to refuse acceptance and promptly feedback to the previous process. The personnel in the previous process need to stop processing immediately, trace the cause, and take measures to detect and correct quality problems in time, and avoid the waste caused by the continued processing of unqualified products.

Oem Pcb Board Manufacturing china

2 Do not manufacture substandard products

Not manufacturing unqualified products means that after accepting the previous qualified products, the operation specifications are strictly enforced in the processing of this position to ensure the processing quality of the products. Preparations such as inspection and confirmation before the operation are fully in place; pay attention to the process conditions during the operation with wild birds to avoid or detect abnormal occurrences early and reduce the probability of non-conforming products. Being fully prepared and confirmed in the process is the key to non-conformity. Only by not producing defective products can it be possible not to flow out and accept defective products.

3 No unqualified products

Non-outflow of unqualified products means that the employees complete the processing of this process and need to check the product quality. Once a defective product is found, it must be shut down in time to cut off the defective product in this process and complete the disposal of the defective product in this process and take preventive measures . This process should ensure that the passed product is qualified and will be rejected by the next process or "customer".