PCBA assembly process of different types of printed circuit boards

The PCBA process involves the process of carrier board, printing, patching, reflow soldering, plug-in, wave soldering, testing and quality inspection. Different types of PCB boards have many different process processes. The differences are explained in detail below for various situations.

1. Single-sided SMT placement

Add solder paste to the component pad. After the solder paste printing on the bare PCB board is completed, mount its related electronic components through reflow soldering, and then perform reflow soldering.

2. Single-sided DIP insertion

The PCB board that needs to be inserted is wave soldered by the production line workers after inserting the electronic components. After welding and fixing, the foot can be washed by washing the board. But wave soldering production efficiency is low.

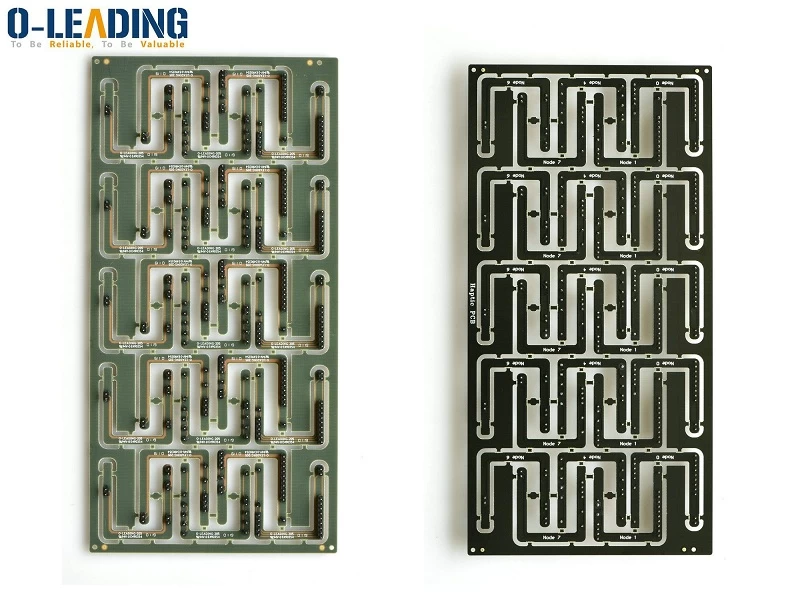

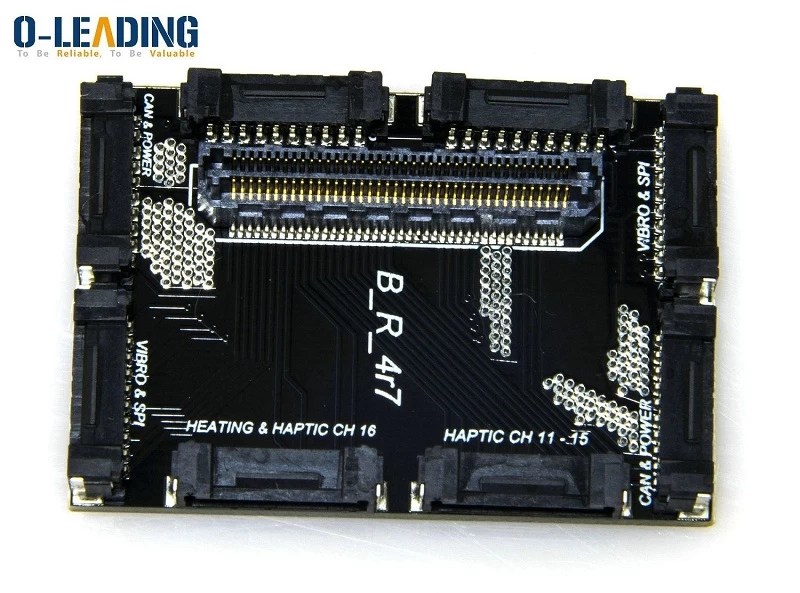

Electronic parts haptic pcba manufacturer Circuit Board assembly pcb for 3D printer

3. Single-sided mixing

The PCB board is printed with solder paste. After mounting the electronic components, it is fixed by reflow soldering. After the quality inspection is completed, the DIP is inserted, and then the wave soldering or manual welding is performed. If there are few through-hole components, manual soldering is recommended. .

4. Mixed single-sided mounting and insertion

Some PCB boards are double-sided, mounted on one side and inserted on the other side. The process flow of placement and insertion is the same as that of single-sided processing, but over-reflow soldering and wave soldering of PCB boards require jigs.

5. Double-sided SMT placement

Some PCB board design engineers will use double-sided mounting in order to ensure the beauty and functionality of the PCB board. Among them, IC components are arranged on the A side, and chip components are mounted on the B side. Make full use of PCB board space to minimize PCB board area.

6. Double-sided mixing

The following two methods are mixed on both sides, the first method is PCBA assembly three times heating, the efficiency is low, and the pass rate of wave soldering using the red glue process is low. The second method is suitable for the case where there are many double-sided SMD components and few THT components. Manual welding is recommended. If there are many THT components, wave soldering is recommended.

electronic oem 4 layer printed circuit board assembly sensor pcba factory

The above merely simplifies the PCBA assembly process of the printed circuit board. However, as the PCBA assembly process and production process are gradually optimized, its non-conformance rate also continues to decrease, ensuring the production of high-quality finished products. The solder joint quality of all the electronic components mentioned above determines the quality of the PCBA board. Therefore, when seeking a PCBA assembling and processing manufacturer, the relevant electronic manufacturers should preferably have rich experience and high level of processing equipment.