Why must PCB require manufacturers to guarantee high reliability?

Reliability = lifeline, is the lifeblood of the success of "electronic products" and "electronic enterprises", should not be underestimated, not to be ignored!

For a product, reliability is a guarantee for the performance of the product. If the product is unreliable, the technical performance will not be achieved even if it is good. "Product reliability" is equivalent to product reliability! In other words, "high reliability" means that the product has a longer lifespan, and there are few or no failures during the product life cycle!

With the rapid development of science and technology, all walks of life have put higher and higher requirements on product reliability! Product reliability has become an indicator of product quality inspection and evaluation, and is also an important weight for companies to enhance competitiveness and brand image!

PCB failure and its consequences

The failure of PCB life cycle is highly related to reliability, and the consequences of failure due to low PCB reliability are also very shocking.

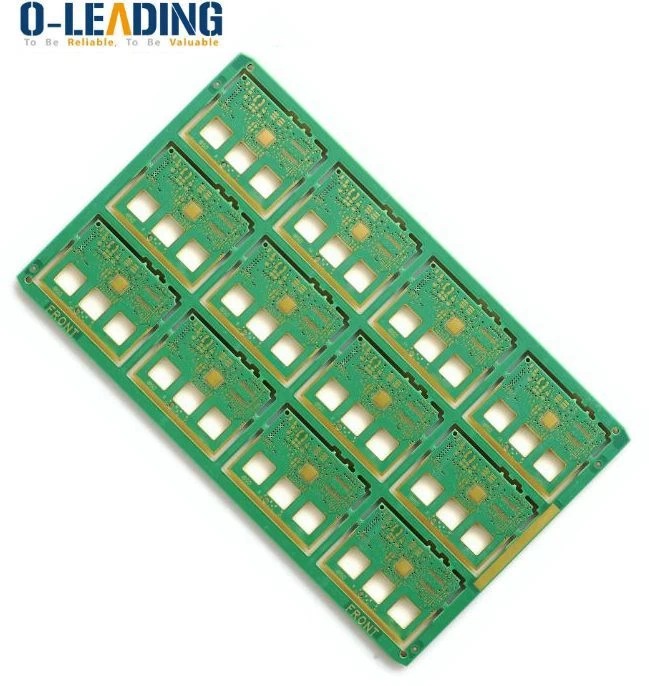

As the carrier of electronic components and the hub of circuit signal transmission, PCB has become one of the most important and critical core components in electronic products. Its quality and reliability level directly determine the quality and reliability of electronic products .

As electronic products are increasingly miniaturized, light-weight, and multi-functional, and the continuous promotion of environmental requirements such as lead-free and halogen-free, the PCB industry is moving towards "thin wires, small holes, multiple layers, thin boards, high TG, high frequency , High-speed, high-density, and environmental protection, which leads to the increasingly complex internal structure of the PCB, increased internal temperature rise, and deterioration of heat dissipation conditions, which greatly affects reliability.

Secondly, the environment in which electronic products are used varies greatly, from tropical to cold, from land to deep sea, from high altitude to cosmic space, from laboratory to wild... In addition to the influence of temperature and humidity, sunlight, dust, and sea water , Salt mist, impact, vibration, cosmic particles, various radiation and other environmental conditions will have varying degrees of impact on the PCB, and even lead to product failure. For example, in the coastal high-salt and high-humidity environment, a thin layer of water film will be formed on the surface of the object, and when the relative humidity is in the air of 65%-80%, the thickness of the water film on the object is 0.001~0.1μm, When the PCB is energized, the water film and the hole copper together form an electrolytic cell, which undergoes an electrochemical reaction and eventually generates black corrosion, which poses a fatal risk to the reliability of the PCB.

The causes of PCB failure are various and different, such as corrosion failure of PTH hole copper, open circuit failure caused by cracks at the bottom of HDI blind holes, layered bursting plate failure, ENIG hole ring crack failure, open short circuit failure, etc., Different types of failures will ultimately affect maintenance costs, operating efficiency, economic benefits, brand image, and may even jeopardize property safety, casualties, and national security!

The importance of high reliability to enhance the competitiveness of electronic products market

In 1992, when my country launched the "Australia", the launch failed due to the failure of a small part, which caused huge economic losses and political impact! Japan’s automobiles, household appliances and other products occupy the international market, mainly because of high product reliability. The overhaul period of the Kangming diesel engine in the United States is 12,000 hours, while domestic diesel engines frequently fail in less than 1,000 hours...

For products, reliability is closely related to "maintenance costs, operating efficiency, property safety, casualties, economic benefits, and national security." High reliability is an important guarantee to enhance the competitiveness of electronic products market!