Will the PCB expire? Bake first after expiration?

Do you know "Why PCBs must be baked before they can be used in the reflow oven after the expiration date exceeds the shelf life"?

The main purpose of PCB baking is to remove moisture and moisture, and to remove the moisture contained in the PCB or absorbed from the outside, because some materials used in the PCB itself easily form water molecules.

In addition, after the PCB is produced and placed for a period of time, there is a chance to absorb moisture in the environment, and water is one of the main killers of PCB popcorn or delamination.

Because when the PCB is placed in an environment where the temperature exceeds 100°C, such as reflow oven, wave soldering oven, hot air leveling or hand soldering, the water will turn into water vapor and then rapidly expand its volume.

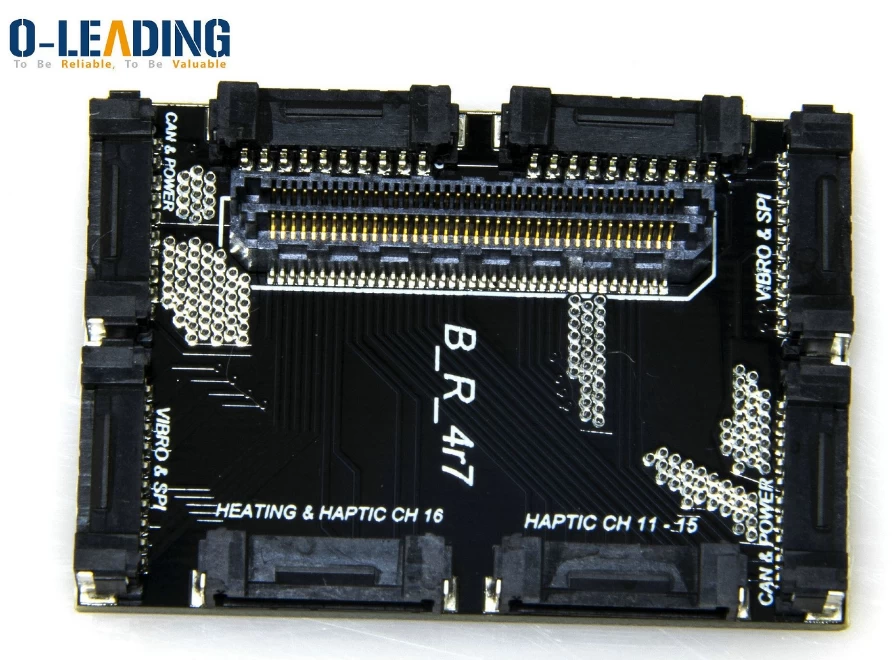

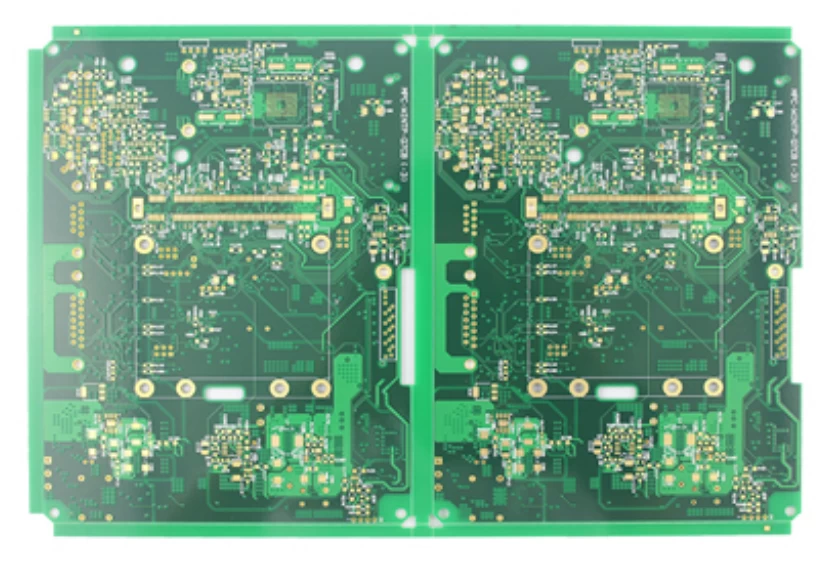

low cost pcb fabrication POE Oem Manufacturing

The faster the heat is applied to the PCB, the faster the water vapor will expand; the higher the temperature, the greater the volume of water vapor; when the water vapor cannot escape from the PCB immediately, there is a good chance of expanding the PCB .

In particular, the Z direction of the PCB is the most fragile. Sometimes the vias between the layers of the PCB may be broken, and sometimes it may cause the separation of the layers of the PCB. Even more serious, even the appearance of the PCB can be seen. Phenomenon such as blistering, swelling, and explosion;

Sometimes even if the above phenomena are not visible on the outside of the PCB, it is actually internally injured. Over time, it will cause unstable functions of electrical products, or CAF and other problems, and eventually cause product failure.

Analysis of the true cause of PCB explosion and preventive measures

The PCB baking procedure is actually quite troublesome. During baking, the original packaging must be removed before it can be put in the oven, and then the temperature must be over 100℃ for baking, but the temperature should not be too high to avoid the baking period. Excessive expansion of water vapor will burst the PCB.

High quality customer HASL lead free FR4 pcb Half hole gold plated PCB

Generally, the PCB baking temperature in the industry is mostly set at 120±5°C to ensure that the moisture can really be eliminated from the PCB body before it can be soldered on the SMT line to the reflow furnace.

The baking time varies with the thickness and size of the PCB. For thinner or larger PCBs, you have to press the board with heavy objects after baking. This is to reduce or avoid PCB The tragic occurrence of PCB bending deformation due to stress release during cooling after baking.

Because once the PCB is deformed and bent, there will be offset or uneven thickness when printing solder paste in SMT, which will cause a large number of solder short circuits or empty soldering defects during subsequent reflow.