What are the functions and types of PCBA coatings?

As the size of the electronic components on the PCBA printed circuit gets smaller and smaller, the density increases more and more; the height of the support between the fixtures and the fixture (the distance between the PCB and the ground clearance) is getting smaller and smaller and the environmental factor also increases the impact on PCBA, so we have put forward higher requirements for the reliability of PCBA electronic products.

China PCBA with conformal coating manufacturer, PCBA three-proof circuit board paint can effectively achieve the protection effects of insulation, moisture, leakage, shock, dust, salt spray, etc., thereby improving the reliability of the circuit board, increasing its safety factor and effectively delaying the service life.

PCBA tri-proof printed circuit board paint is widely used in high-tech industries, such as high-end printed circuit boards in automobiles, home appliances, military electronics, aerospace, medical electronics, etc., which can improve the quality of PCBA printed circuit boards and effectively reduce rework. In addition, the rise of emerging industries, the widespread use of charging batteries for electric vehicles, and the widespread use of unmanned aircraft have further expanded the scope of the three-proof paint application. At present, it has become a major trend to coat the three-proof paint on PCBA for protection.

Tri-proof paint is used to protect PCBA circuit boards and related equipment from environmental erosion. The three-proof paint coating process is a necessary process link in production rather than "icing on the cake". Its function is mainly to improve product reliability, especially in harsh operating environments. Coated conformal paint protects electronic products from external factors such as extreme heat, humidity, humidity and dust. At the same time, it can also protect electronic products from internal factors such as corrosion, whisker growth and short circuits in the system. In short, the three-proof paint is equivalent to an insulating layer to ensure the normal operation of different components and avoid premature PCB failure.

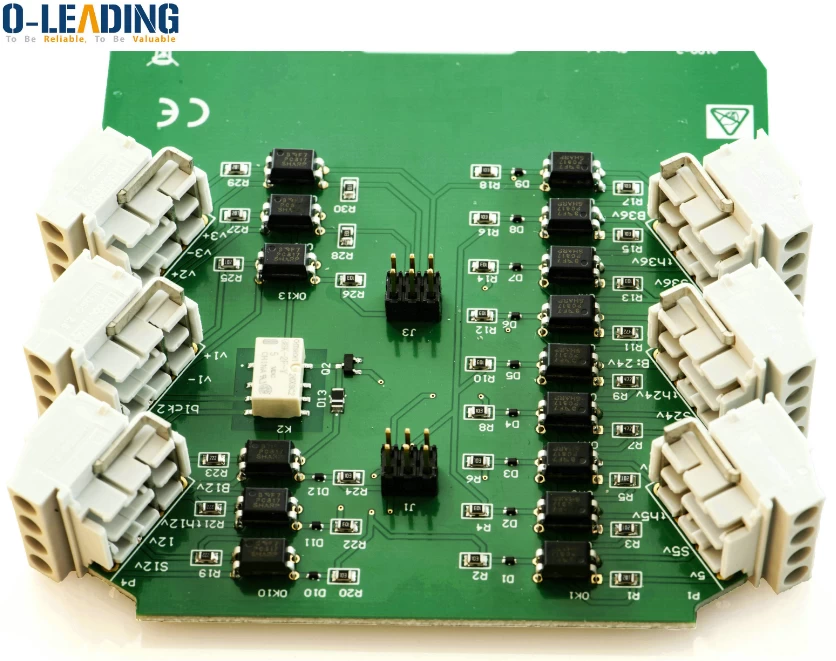

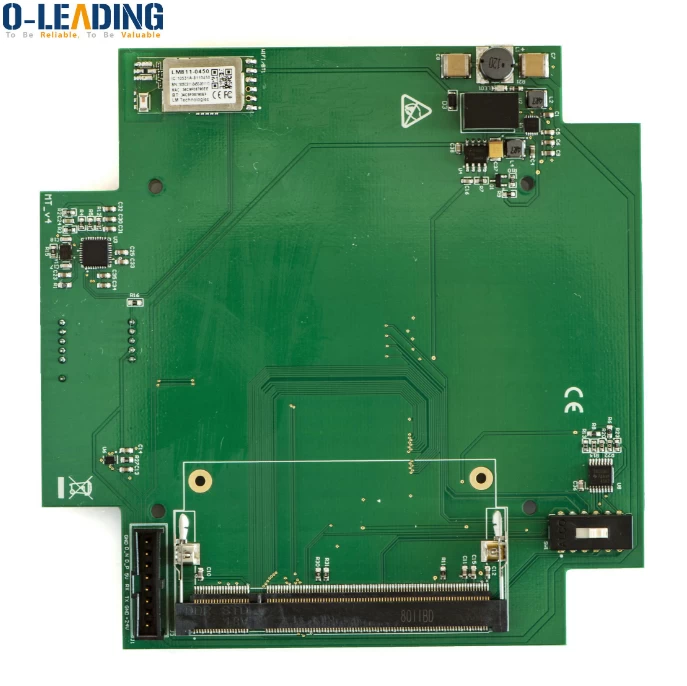

O-leading Compliant coated electronic circuit pcba manufacturer service for warmhouse pcb board

Three anti-paints are called according to the requirements and focus of each region and each manufacturer, such as three anti-glue, moisture-proof glue, insulating glue, moisture-proof paint, protective paint, protective paint, glue for coating, coating glue, waterproof glue, moisture-proof oil, three-proof oil, three-proof agent, protective agent, moisture-proof agent, conformal coating, conformal coating, conformal coating, common coating, the English name it is compliant coating.

Types of three anti-paints:

Three anti-paints can be divided into room temperature curing, thermal curing and light curing in terms of curing methods. Three anti-paints can mainly be divided into acrylic resin (acrylic, type AR), epoxy resin (epoxy, type ER) and silicone (silicone, type SR), polyurethane resin (urethane, type UR) and parylene (type XY) five categories , etc.