What are the special points of FPC wiring?

FPC wiring should give priority to ensuring smooth signal routing. The principle of short, straight, and less perforation is the principle. Try to avoid long, thin and circle routing. Use horizontal, vertical and 45-degree lines as the main line to avoid arbitrary angles. The curved part follows the arc line.(Flex printed circuit board supplier)

1. Line width: Considering that the line width requirements of the data line and power line are inconsistent, the reserved wiring space is 0.15mm on average;

2. Line pitch: According to the current production capacity of most manufacturers, the design line pitch (Pitch) is 0.10mm;

3. Line margin: The distance between the outermost line and the FPC contour is designed to be 0.30mm, and the larger the space is, the better;

4. Internal fillet: The minimum internal fillet on the FPC profile is designed to be radius R=1.5mm;

5. The wire is perpendicular to the bending direction;

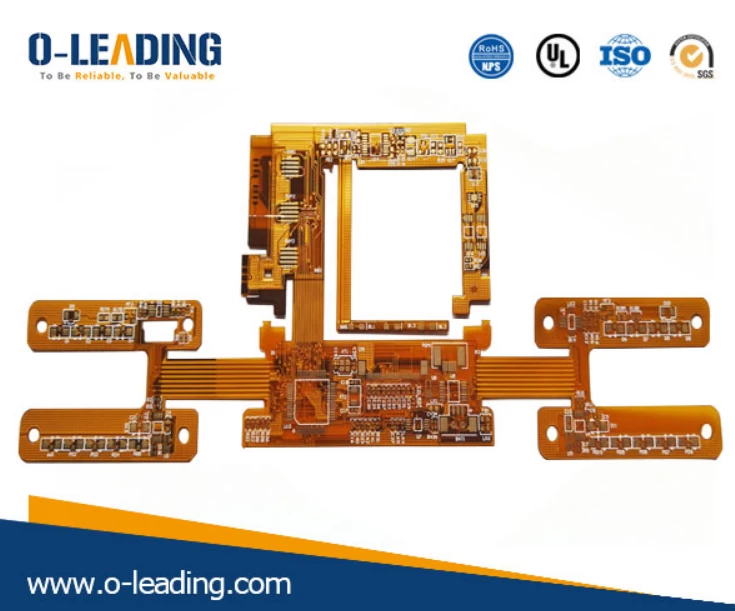

Customized double-Sided and single-sided Flexible FPC

6. The wire should pass through the bending area evenly;

7. The wire should be as full as possible in the bending area;

8. There should be no additional plating metal in the bending area (the wires in the bending area are not plated);

9. Keep the line width consistent;

10. The wiring of the double panel cannot overlap to form an "I" shape;

11. Minimize the number of layers in the bending area;

12. The bending area cannot have via holes and metallized holes;

13. The bending center axis should be set at the center of the wire. The material coefficient and thickness on both sides of the wire should be as consistent as possible. This is very important in dynamic bending applications.

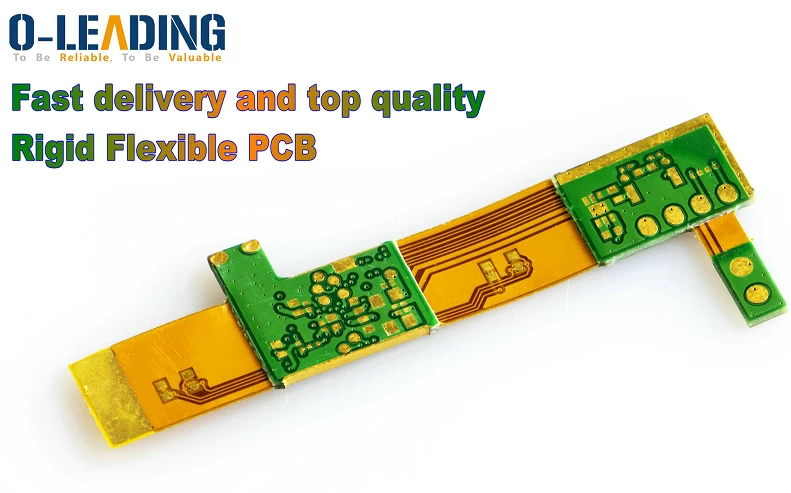

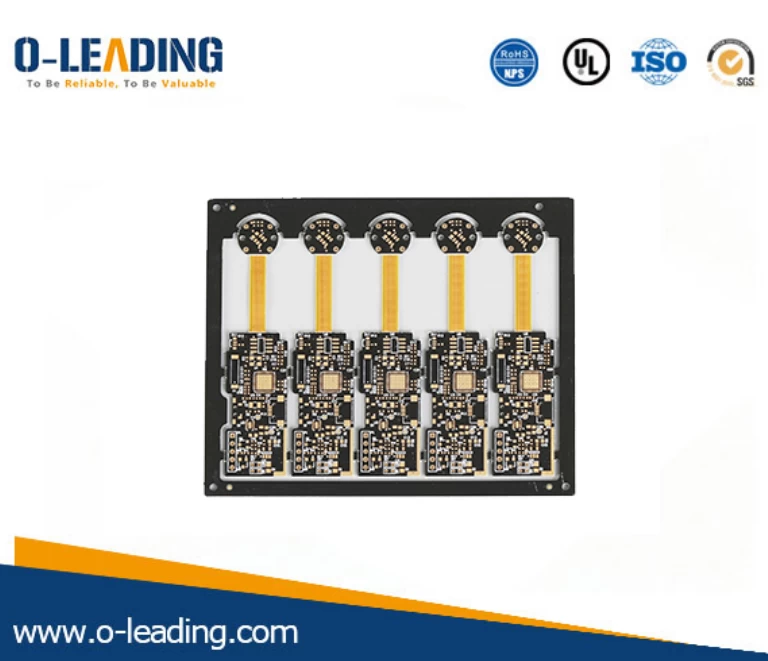

China professional flexible pcb and Rigid flex pcb board Wholesale

14. Horizontal plane torsion follows the following principles-reduce the bending section to increase flexibility, or partly increase the area of copper foil to increase flexibility.

15. For vertical surface bending, increase the bending radius and reduce the number of layers in the central area of the bending.

16. For products with EMI requirements, if high-frequency radiation signal lines such as USB, MIPI, etc. are on the FPC, a conductive silver foil layer should be added to the FPC according to the EMI measurement situation and the conductive silver foil should be grounded to prevent EMI.