Why should small batch PCB assembly be the preferred method for all industrial projects?

As printed circuit boards become an indispensable part of more and more devices, PCB prototyping has been unprecedentedly high. As the company continues to innovate, the hourly demand is small batch PCB assembly, which can provide high turnaround time, and manufacturers will not get into trouble due to unavailable high inventory.

The following are some unique advantages of low-volume PCB assembly, which are of great value to manufacturers:

1. Cost advantage-Although traditional economies of scale will bring high output, in the ever-changing technical solutions, small batch PCB production has a significant cost advantage. First, you will not produce more circuit boards than you need. Moreover, as technology continues to change, these boards will not become redundant.

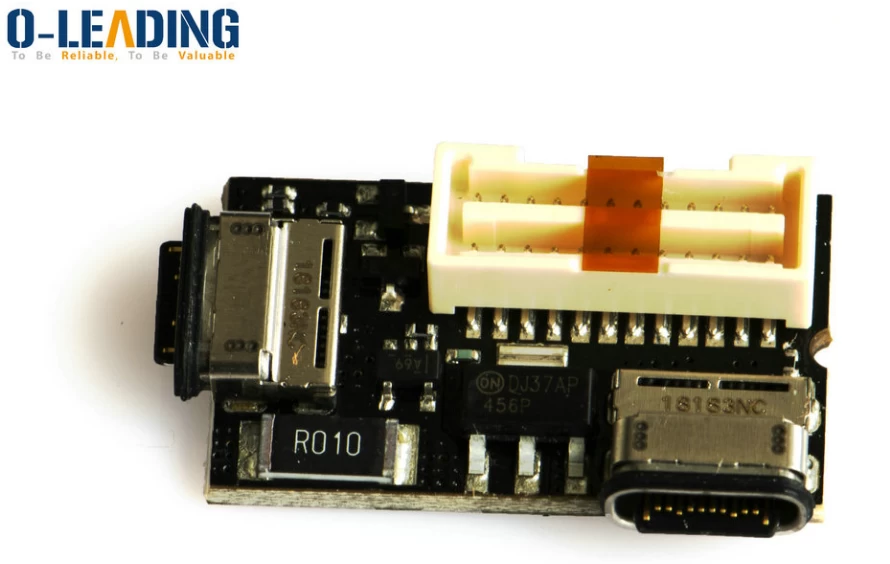

Industrial controller SMT assembly factory pcba

In the prototype stage, you often improvise on product design and functionality. Low-volume production means you will not be bothered by defective products. Similarly, since you can outsource PCB components in small quantities, it means lower overhead costs for your own business. You can also save valuable time that can be used in other productive business areas. For lower batches, you also tend to save on storage costs that may increase, just in case you bear a heavy inventory load. If the prototype fails, this will also be useless inventory. Therefore, small batch PCB assembly can provide a low-cost test method

2. Turnaround time-Small batches also bring fast turnaround time. Therefore, you can quickly evaluate whether to make any design changes. In turn, this shortens the time to market, which can be a source of important competitive advantage in today's world.

3. Agility-If there is an attribute between business success and failure, then the enterprise's agility to respond to changes. Small batch PCB assembly essentially provides enterprises with this advantage, because enterprises will not be troubled by mass production and have the advantage of short turnaround time. By improving the ability to check whether the product has defects and whether the design needs to be changed, companies can flexibly match their products to customer needs. Needless to say, there are more and more opportunities for success.

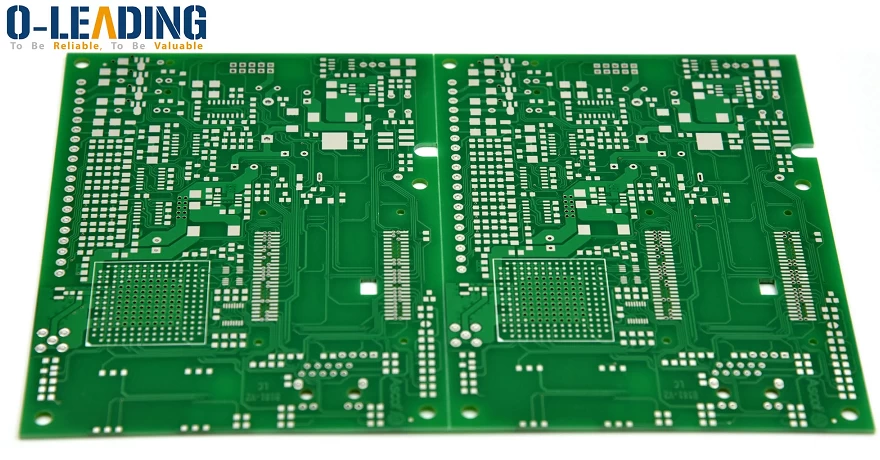

OEM electronic printed circuit board manufacturer electronic controller board

4. High-quality final product-PCB prototype has a short turnaround time and the ability to find defects early. You have the advantage of improving the product, so you can enter the market with high-quality products. As the product succeeds in the market and brings reputation to the manufacturer, this greatly improves credibility.

5. It is also feasible for startups and hobbyists-these days business is no longer just the domain of large enterprises. With low-volume PCB assembly and the low cost associated with testing ideas, the business has become a level playing field. For small businesses and hobbyists, it is easy to test their ideas without investing a lot of money. For start-ups that want to sell to investors, in addition to a paper business plan, it is easy to obtain a proof of concept.

All in all, small-batch PCB assembly has several advantages. The first is to save management costs by outsourcing work. Small orders will automatically shorten the turnaround time. Moreover, this is a simple and low-cost method of testing product design ideas without incurring a lot of cost.