Analysis and solution of copper plate copper plating failure

Based on many years of experience in electroplating and technical services, the author summarizes the following and hopes to inspire the electroplating industry in the PCB industry. The common problems of acid copper plating are as follows: 1. Rough plating; 2. Electroplating (plate surface) copper particles; 3. Plating pits; 4. The board is white or uneven in color. In response to the above questions, some conclusions were made and some brief analysis and prevention measures were carried out.

Rough plating: Generally, the plate angle is rough, and most of them are caused by large plating current. You can reduce the current and check the current with the card meter to show whether there is any abnormality. The whole plate is rough and generally does not appear, but the author has met once at the customer. Later, when the temperature was found to be low in winter, the amount of light agent was insufficient; and sometimes some reworked membranes were not clean and the surface treatment would be similar.

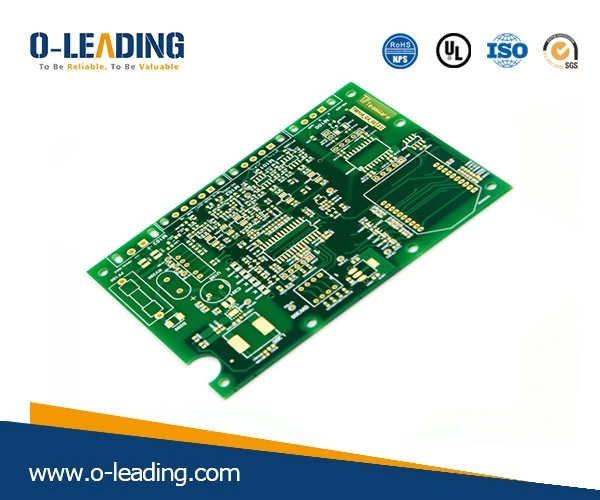

PCB products are used in Digital Products.

Copper plate on the plate surface: There are many factors that cause the copper particles on the plate surface. From the process of sinking copper and transferring the pattern, the copper plate plating of the PCB plate itself is possible. The author has met in a state-owned factory, the copper surface caused by copper.

The copper on the surface caused by the copper sinking process may be caused by any copper processing step. Alkaline degreasing is high in water hardness and has a lot of drilling dust (especially if the double-panel does not remove the slag). It will not only cause rough surface, but also cause roughness in the hole; The inner roughness is slight, and the slight punctate dirt on the surface of the board can also be removed; the micro-etching mainly has several cases: the micro-etching agent used is too poor in hydrogen peroxide or sulfuric acid or the ammonium persulfate (sodium) contains too much impurities, generally It is recommended that it should be at least CP-level. In addition to this, the industrial grade will cause other quality failures; the copper content in the micro-etching tank is too high or the temperature is low, causing the copper sulfate crystals to slowly precipitate; the bath liquid is turbid and polluted.

PCB products are used in Security Products.

Most of the activation fluid is caused by pollution or improper maintenance. For example, the filter pump leaks, the specific gravity of the bath is low, and the copper content is high (the activation tank is used for too long, more than 3 years), which will produce granular suspension in the bath. Or an impurity colloid, adsorbed on the surface of the plate or the wall of the hole, which is accompanied by the occurrence of roughness in the hole. Debonding or accelerating: the bath is used for too long and turbid, because most of the debonding solution is now prepared with fluoroboric acid, so that it will attack the glass fiber in FR-4, causing the silicate in the bath, the rise of calcium salt High, in addition, the increase in copper content and amount of dissolved tin in the bath will cause the formation of copper on the surface.