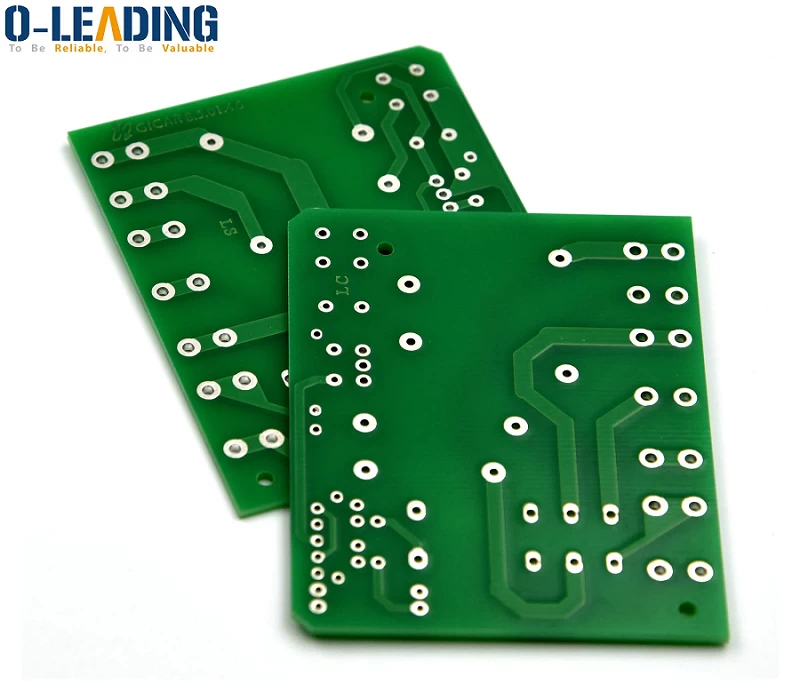

Double-sided printed circuit board

Double-sided circuit board features:

The difference between single-sided circuit boards and double-sided circuit boards is the number of copper layers. A double-sided circuit board has copper on both sides of the circuit board, and can be connected through vias for connection. There is only one layer of copper on one side, and only simple lines can be made, and the holes can only be used for plug-ins and cannot be connected. The technical requirements of the double-sided circuit board are that the wiring density becomes larger, the hole diameter is smaller, and the hole diameter of the metallization hole is getting smaller and smaller. The quality of the metallized holes on which the layers are interconnected depends directly on the reliability of the printed board. As the pore size decreases, debris that has no effect on the larger pore size, such as grinding debris and volcanic ash, once remaining in the small hole, will make the chemical copper sink and electroplated copper useless, and the hole will be free of copper and become a hole. Metallized killer.

Welding method of double-sided circuit board

Double-sided circuit board In order to ensure the reliable conductive effect of the double-sided circuit, the connection hole (that is, the through-hole portion of the metallization process) of the double-sided board should be welded with wires or the like, and the protruding part of the connection wire tip should be cut out to avoid stab Injury to the operator's hand, this is the board wiring preparation.

EMS manufacturer UL approved power supply pcba and power supply pcb and power supply board

Essentials for welding double-sided circuit boards:

1. Devices that require reshaping should be processed according to the requirements of the process drawings; that is, reshaping first and then plugging in.

2. After the shaping, the model side of the diode should face upward, and there should be no inconsistency between the lengths of the two pins.

3. When inserting devices with polar requirements, pay attention to that their polarities must not be reversed, and roller integrated block components, after insertion, no vertical or horizontal devices, there must be no obvious tilt.

4. The power of the soldering iron used for soldering is between 25~40W. The temperature of the soldering iron tip should be controlled at about 242°C. If the temperature is too high, the head is easy to "dead". If the temperature is low, the solder cannot be melted. The soldering time is controlled at 3. ~4 seconds.

5. During the formal welding, generally follow the welding principle of the device from short to high, and from the inside out. The welding time should be mastered. If the time is too long, the device will be burned, and the copper line on the copper clad board will be damaged.

6. Because it is double-sided soldering, it is also necessary to make a process frame for placing the circuit board and the like, the purpose is not to slant the device below.

7. After the circuit board welding is completed, a full-numbered seating inspection should be carried out to check for missing insertion and soldering. After confirmation, trim the excess device pins of the circuit board and the like, and then flow into the next process.

8. In the specific operation, it should also strictly follow the relevant process standards to ensure the welding quality of the product.

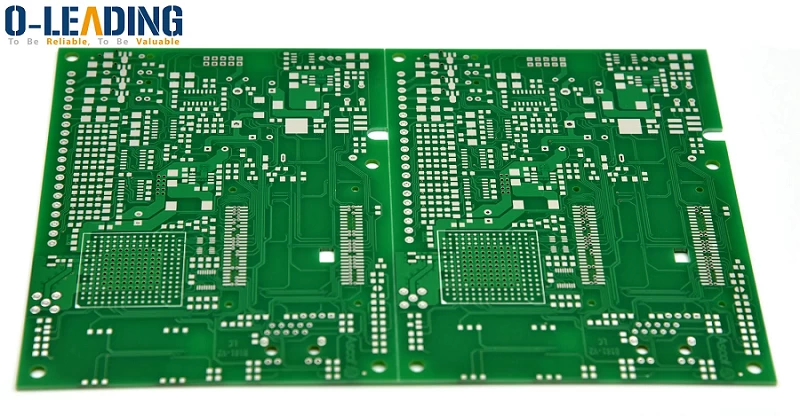

Industrial Control PCBA Customize Multilayer Printed Circuit Board

With the rapid development of high technology, electronic products that are closely related to the public are constantly being updated. The public also needs electronic products with high performance, small size, and multiple functions, which puts new requirements on circuit boards. This is why the double-sided circuit board was born. Due to the wide application of double-sided circuit boards, the printed circuit board manufacturing has also been developed to be light, thin, short and small.

O-Leading strives to be your one stop solution partner in EMS supply chain, and make persistent efforts on PCB & PCBA one-stop service to provide first-class services and create more value for our customers.