Why can't the crystal be placed on the edge of the PCB?

For a driving recorder, an external adapter should be added during the test. When the machine is powered on, the test is found to be excessive. The specific frequency is 84MHZ, 144MH, 168MHZ. It is necessary to analyze the cause of the radiation exceeding the standard and give corresponding countermeasures. Multi Layer PCB manufacturer china.

2. Radiation source analysis:

The product has only one PCB with a 12MHZ crystal on it. The over-standard frequency point is exactly the frequency multiplier of 12MHZ, and the screen and camera with easy EMI radiation exceeding the standard are analyzed. It is found that the LCD-CLK is 33MHZ, and the camera MCLK is 24MHZ. After eliminating the camera, the over-standard point still exists. By shielding the 12MZH crystal, the over-punctuation point is reduced, thereby judging that the 144MHZ super-punctuation point is related to the crystal. Flex printed circuit board supplier.

3. Principle of radiation generation:

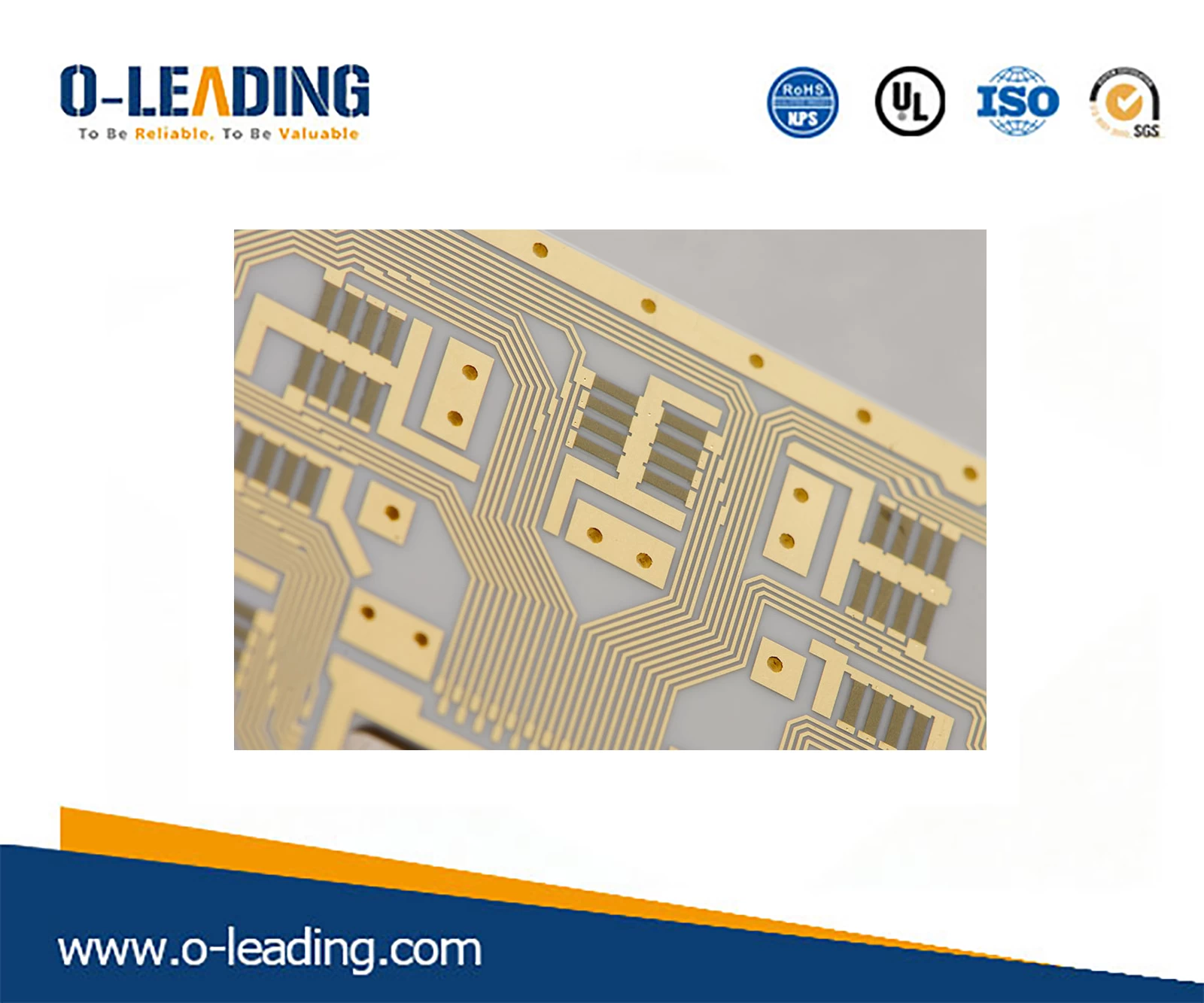

As can be seen from the PCB layout, the 12MHZ crystal is placed on the edge of the PCB. When the product is placed in the test environment of radiation emission, the high-speed device of the tested product and the reference ground in the laboratory will form a certain capacitive coupling. Parasitic capacitance leads to common mode radiation. The larger the parasitic capacitance, the stronger the common mode radiation. The parasitic capacitance is the electric field distribution between the crystal and the reference ground. When the voltage between the two is constant, the electric field distribution between the two is constant. The more the electric field strength between the two, the larger the parasitic capacitance will be. 1200mm Aluminum Based PCB.

When the crystal oscillator is placed in the middle of the PCB or far from the edge of the PUB, most of the electric field is controlled between the crystal oscillator and the working ground due to the presence of the working ground (GND) plane in the PCB, that is, inside the PCB, distributed to the reference junction. The electric field that the floor goes to is greatly reduced, resulting in a decrease in radiation emission.

4. Treatment measures

Move the crystal oscillator inwardly to a distance of at least 1 cm from the edge of the PCB, and apply copper to the surface of the PCB 1 cm away from the crystal, while connecting the copper of the surface layer to the ground plane of the PCB through the via. The spectrum of the modified test results is as follows. As can be seen from the figure, the radiation emission has been significantly improved.