Selection techniques of magnetic beads in PCB circuit design

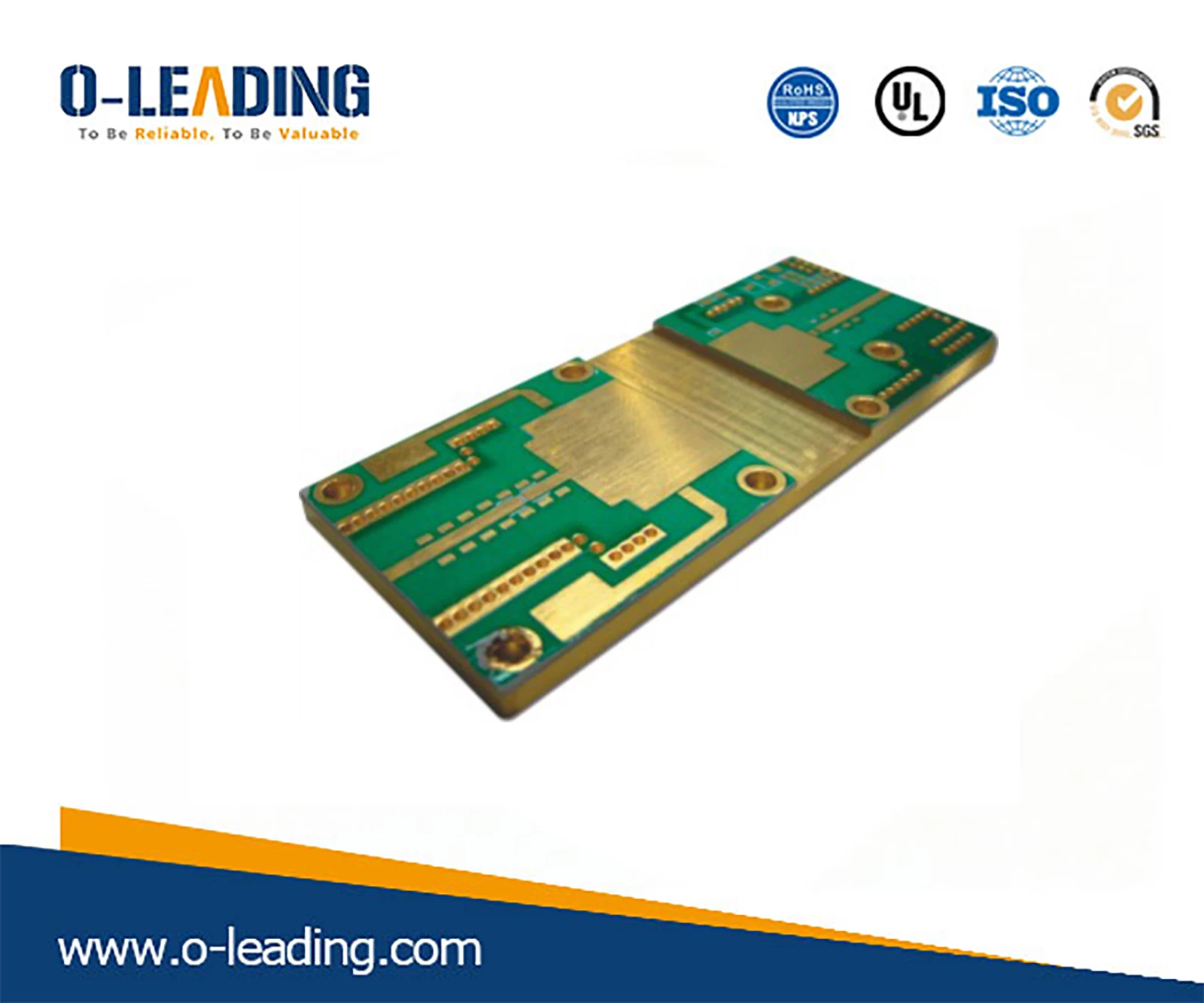

The reason for using patch beads and chip inductors is whether the use of chip beads or chip inductors is mainly in applications. A chip inductor is required in the resonant circuit. When you need to eliminate unwanted EMI noise, using patch beads is the best choice. Telecommunication PCB supplier china.

Different ferrite suppression elements have different optimal suppression frequency ranges. Generally, the higher the magnetic permeability, the lower the frequency of suppression. In addition, the larger the volume of the ferrite, the better the suppression effect. I have studied some big cattle on the scheme website and found that when the volume is constant, the long and thin shape is better than the short and thick one. The smaller the inner diameter, the better the suppression effect. However, in the case of DC or AC bias current, there is also a problem of ferrite saturation. The larger the cross-section of the suppression element, the less likely it is to saturate and the greater the bias current that can be withstood. Golden Fingers PCB manufacturer china.

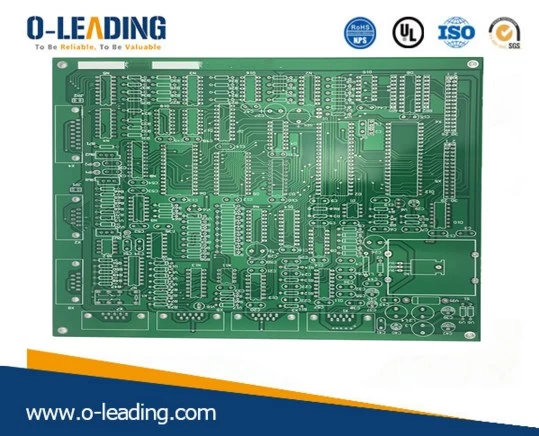

When the EMI absorption magnetic ring/bead suppresses the differential mode interference, the current value through it is proportional to its volume, the two are out of regulation, causing saturation, which reduces the performance of the component; when suppressing common mode interference, the two wires of the power supply (positive and negative) At the same time, through a magnetic ring, the effective signal is the differential mode signal, the EMI absorption magnetic ring/magnetic bead has no influence on it, and the common mode signal shows a large inductance. A better method of using the magnetic ring is to repeatedly circulate the wire of the magnetic ring that passes through to increase the inductance. According to its suppression principle of electromagnetic interference, its suppression can be reasonably used. Multilayer PCB manufacturer china.

The ferrite suppression element should be installed close to the source of the interference. For the input/output circuit, it should be as close as possible to the entrance and exit of the shield case. For the absorption filter composed of the ferrite magnetic ring and the magnetic beads, in addition to the use of high magnetic permeability consumable materials, it is also necessary to pay attention to its application. Their resistance to high-frequency components in the line is about ten to several hundred ohms, so its role in high-impedance circuits is not obvious. Instead, in low-impedance circuits (such as power distribution, power or RF circuits) Use will be very effective.

Ferrite is widely used in EMI control because it can attenuate higher frequencies while allowing lower frequencies to pass almost unimpeded. The magnetic ring/magnetic beads for EMI absorption can be made into various shapes and are widely used in various applications. For example, on the PCB board, it can be added to DC/DC modules, data lines, power lines, etc. It absorbs high-frequency interference signals on the line, but does not generate new poles in the system, and does not damage the stability of the system. It is used in conjunction with the power filter to complement the high-frequency performance of the filter and improve the filtering characteristics of the system.

Magnetic beads are designed to suppress high-frequency noise and spikes on signal lines, power lines, and the ability to absorb electrostatic pulses.