Reasons for high cold welding rate of μBGA and CSP in hot air reflow soldering

Under the same peak temperature and reflow time, the heat obtained by the μBGA and CSP solder joints will be significantly insufficient compared with other components with good solder joints in hot air, resulting in some μBGA, CSP. The bottom solder ball solder joint temperature does not reach the wetting temperature and cold soldering occurs.

In the above state, during the re-flow soldering process of μBGA and CSP, the heat transfer can only be performed by first heating the μBGA, CSP package and PCB, and then relying on heat transfer from the package and PCB substrate to the pad and μBGA, CSP solder. Ball, forming a solder joint. For example, if hot air at 240 °C acts on the surface of the package, the pads and the μBGA, CSP solder balls will gradually heat up, and the temperature rise will appear a lag time compared to other components, if the reflow is not required. Cold welding occurs when the time rises to the required wetting temperature.

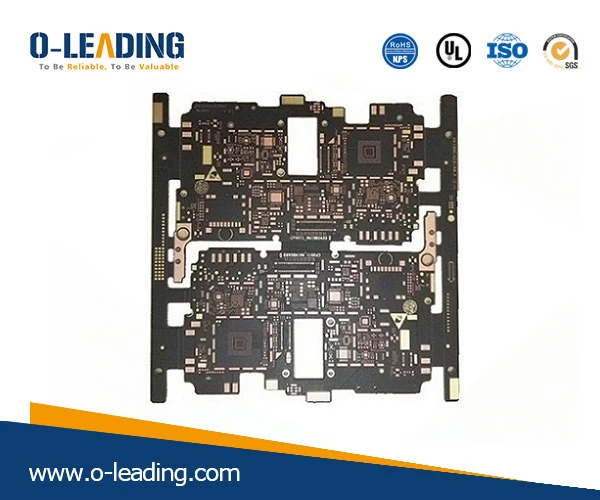

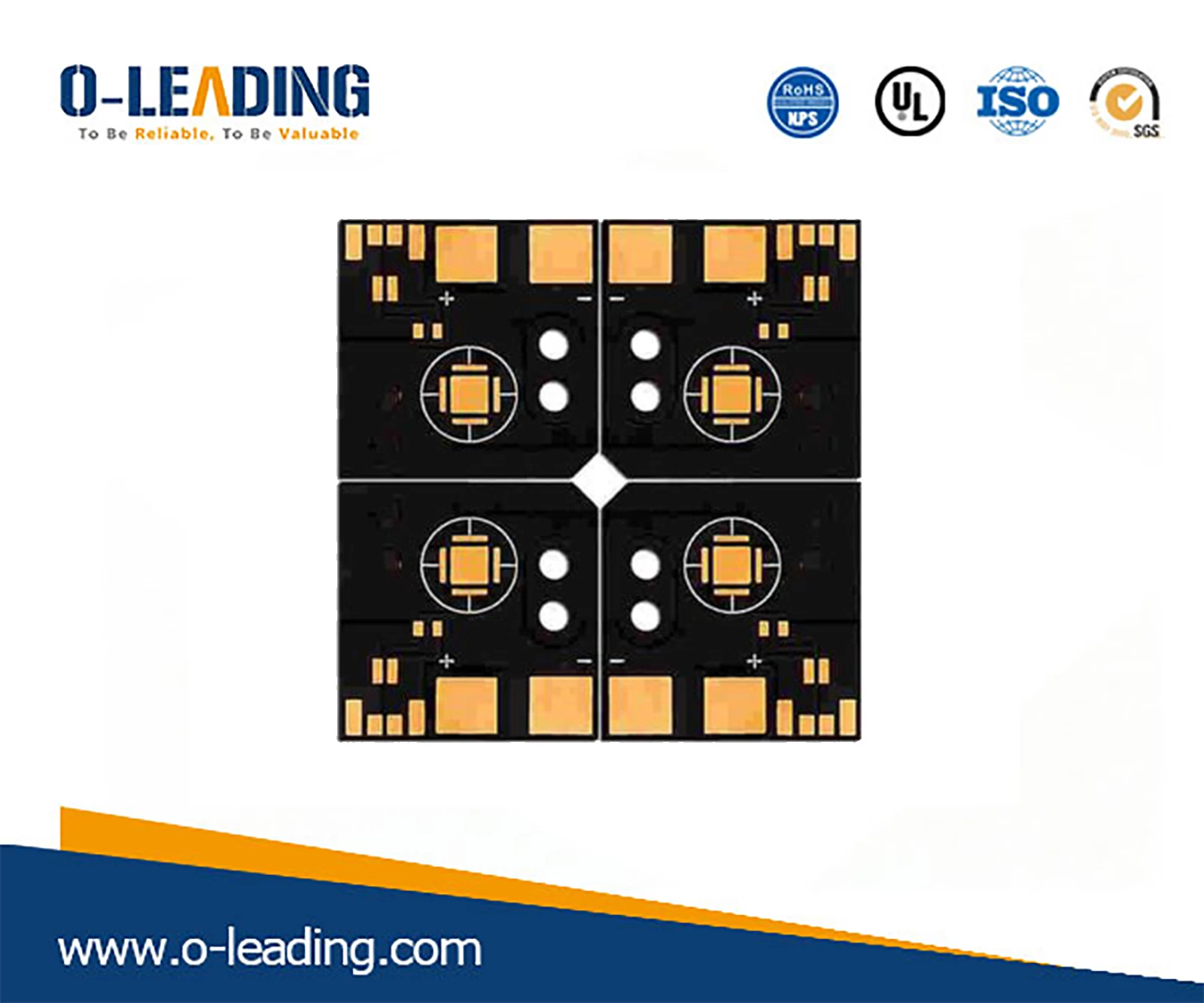

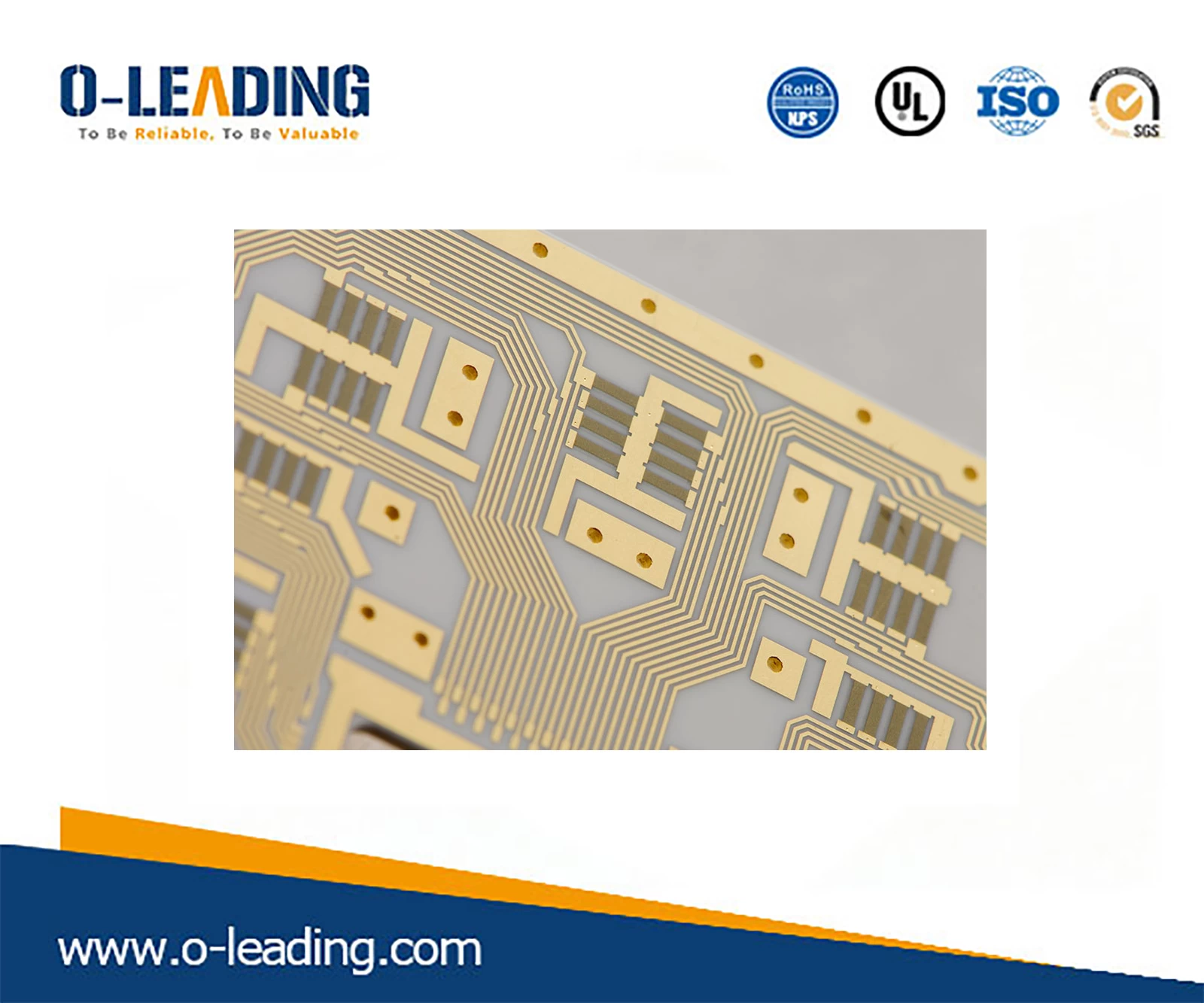

PCB with Copper Filling wholesales.

Possible measures to solve the high incidence of μBGA and CSP cold welding

(1) Use trapezoidal temperature curve (extended peak temperature time)

Appropriately reducing the reflow peak temperature and extending the peak temperature time can improve the temperature difference between the heat dissipation capacity component and the large heat capacity component, and avoid overheating of the smaller components.

A modern hybrid reflow system reduces the temperature difference between a 45mm BGA and a small lead package (SOP) package to 8°C.

PCB Assembly manufacturer china.

(2) Improve the supply method of reflow soldering heat

Reflow soldering is the soldering of thousands of components to a PCB substrate. If there are components of different quality, heat capacity, and area on a single PCB, temperature non-uniformity will be formed. The two most common reflow heat supply methods and their characteristics in the industry are as follows:

1 Forced convection heating. Forced hot air convection reflow soldering is a reflow soldering method that uses a convection jet nozzle to force the airflow to circulate, thereby heating the soldered part, as shown in Figure 16. The temperature of the PCB substrate and components using this heating method is close to the gas temperature of a given heating zone, which overcomes the large temperature difference between components due to the difference in appearance color and the surface reflection of components due to infrared heating. The problem.

2 infrared heating. Infrared (IR) is an electromagnetic wave having a wavelength of 3 to 10 μm. Usually, materials such as PCBs, fluxes, and components are packaged by atomic-chemically bonded molecular layers that constantly vibrate due to molecular expansion and contraction. When the vibrational frequencies of these molecules are in contact with similar infrared electromagnetic waves, these molecules resonate and the vibration becomes more intense. Frequent vibrations generate heat, and heat can be quickly and evenly transmitted to the entire object in a short period of time. Therefore, the object does not need to be heated from the outside at a high temperature, and the object is sufficiently heated. The cooling is also helpful.