PCB technology trends are developing on the corner

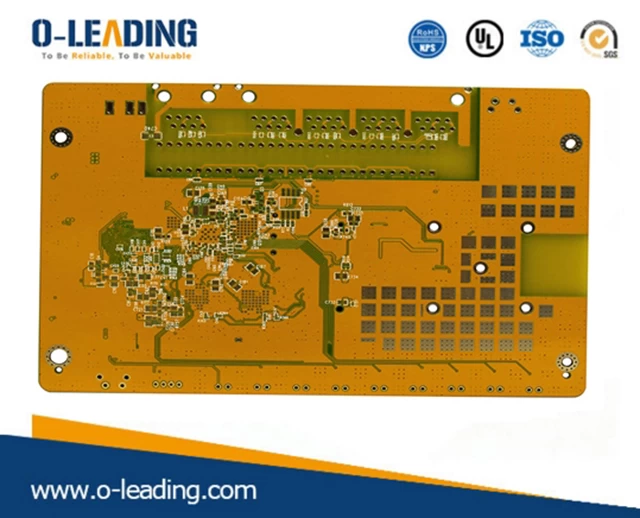

Along with the miniaturization and high function of electronic devices, high heat generation is generated, and the thermal management requirements of electronic devices are increasing. One solution selected is to develop a thermally conductive printed circuit board. PCBs are required to have high thermal conductivity and heat resistance, and efforts have been made for the past decade. High heat dissipation PCBs such as flat thick copper substrate PCB, aluminum metal based PCB, aluminum metal core double-sided PCB, copper-based planar PCB, aluminum-based cavity PCB, embedded metal block PCB, flexible aluminum-based PCB, etc. .

The metal substrate (IMS) or metal core printed circuit board is used to dissipate heat from the heat generating component, which reduces the volume and reduces the cost compared with the conventional heat sink and fan cooling. At present, metal substrates or metal cores are mostly metal aluminum. The advantages of aluminum-based circuit boards are simple and economical, reliable electronic connection, high thermal conductivity and high strength, no soldering, lead-free environmental protection, etc., and can be designed and applied from consumer products to automobiles, military products and aerospace.

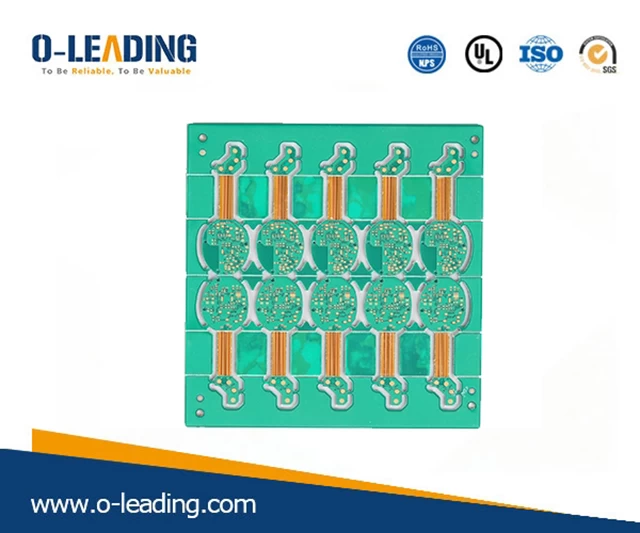

New trend in flexible and rigid plate technology

The miniaturization and thinning of electronic equipment have inevitably used a large number of flexible printed circuit boards (FPCB) and rigid-flex printed circuit boards (R-FPCB).

As the application grows, there are many new performance requirements in addition to the increase in number. Polyimide films are colorless, transparent, white, black and yellow, with high heat resistance and low CTE properties, suitable for different occasions. Cost-effective polyester film substrates are also available in the market. New performance challenges include high flexibility, dimensional stability, film surface quality, and film opto-coupling and environmental resistance to meet the changing needs of end users.

printed circuit boards supplier

FPCB has the same high-speed and high-frequency signal transmission requirements as rigid HDI boards. The dielectric constant and dielectric loss of flexible substrates must be concerned. Polytetrafluoroethylene and advanced polyimide substrates can be used to form flexible circuits. . The addition of an inorganic powder and a carbon fiber filler to the /polyimide resin produces a three-layer structure of a flexible thermally conductive substrate. The inorganic fillers selected are aluminum nitride (AlN), aluminum oxide (Al 2 O 3 ) and hexagonal boron nitride (HBN).

FPCB manufacturing technology, direct metallization on polyimide (PI) film to produce double-sided FPCB technology has been developed, there is a new technology of molecular cement aqueous solution, does not change the surface roughness of PI film can increase and chemical sink Copper layer bonding strength. The PI film is used for molecular bonding and direct electroless copper plating. The semi-additive process is used to produce a double-sided flexible printed circuit board, which simplifies the process and is environmentally friendly, and meets the requirements for bonding strength, flexibility and reliability.

There is also a printed autocatalytic electronic circuit technology for roll-to-roll production (R2R), which first prints an autocatalytic ink on a PET film and then enters an electroless copper plating bath because the ink has autocatalytic ability on the ink. A copper layer is deposited to form a copper conductor pattern, and the metal thin circuit on the PET film is completed.

FPCB application markets such as smart phones, wearable devices, medical devices, robots, etc., put forward new requirements for FPCB performance structure and developed new FPCB products. For ultra-thin flexible multi-layer boards, the four-layer FPCB is thinned from the conventional 0.4 mm to about 0.2 mm; the high-speed transmission flexible board uses low Dk and low Df polyimide substrates to achieve 5 Gbps transmission speed requirements;

High-power flexible board with thick conductor of more than 100 μm to meet the needs of high-power and high-current circuits; high-heat-dissipation metal-based flexible board is R-FPCB for partial use of metal plate substrate; tactile inductive flexible plate, by pressure The sensing film and the electrode are sandwiched between two polyimide films to form a flexible tactile sensor; a flexible flexible plate or a rigid-flexible plate, the flexible substrate is an elastic body, and the shape of the metal wire pattern is improved. adjustable.