PCB process edge design

When the PCB is to be processed for SMT placement, the PCB is transported on the SMT production line through guide rails. Therefore, a pair of edges of the forbidden cloth components must be left as the transmission edges. Usually, the two long sides of the large board after the PCB or puzzle board are used as its transmission sides.When the PCB is to be processed for SMT placement, the PCB is transported on the SMT production line through guide rails. Therefore, a pair of edges of the forbidden cloth components must be left as the transmission edges. Usually, the two long sides of the large board after the PCB or puzzle board are used as its transmission sides.

The width of the SMT transport track fixing plate is 3.0mm. The theoretical limit value of the transport side is 3.0mm, but it is recommended that you do not go to this limit and increase the difficulty of placement. To leave a little more space as a margin, it is recommended to use 5.0mm as the "prohibited area" of the transmission edge.

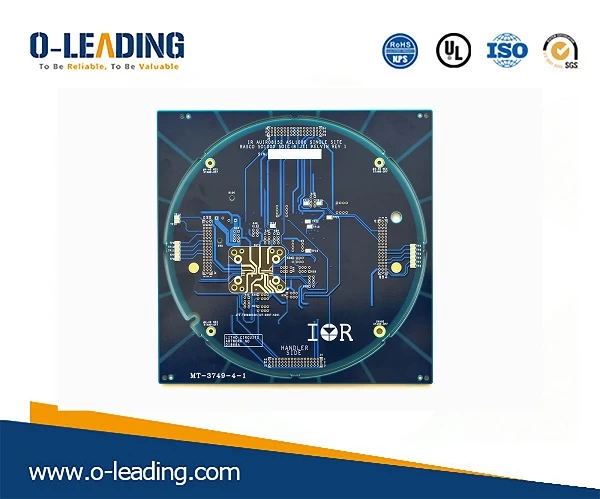

Double Side PCB manufacturer china

If the distance between the patch part in the board and the board edge is far enough, it will not be in the track range, then no additional process edge is needed. If the part is in the track range, a process edge must be added, and the process edge is used as the clamping area. According to the characteristics of the machine, the width of the craft side usually needs 3-10mm, and 5mm is the most common.

Generally, the side of the process is added to the longer side. The board enters the SMT machine vertically. This way, the hardness of the board is relatively high. The patch will not bounce due to the light pressure of the machine probe. The average price of a single board. If the hardness of the board is sufficient, it can be added in a short direction, the area of the process edge is small, the average cost of a single board is reduced, and the board enters the SMT machine horizontally.

Multi Layer PCB manufacturer china

SMT usually uses MARK points for alignment. If there are no MARK points in the board, you must add 2-4 MARK points diagonally on the side of the process. The size of the MARK points is generally 1.0mm, and the copper is exposed to tin. Next, the craft side can be added or not added.

When the board factory is producing, forming and testing need positioning. Adding special positioning holes on the side of the craft makes the shape relatively standard and makes positioning easier. Therefore, 3-4 positioning holes with a diameter of 2.0-4.0mm will be added on the craft side. The diameter of 3mm is the most common and is best used.

Flex printed circuit board supplier

Design considerations for craft edges:

1. SMD or machine-inserted components cannot be arranged in the craft side, and the entity of the patch or machine-inserted components cannot enter the craft side and its space.

2.The entity of the hand-inserted component cannot fall in the space within 3mm height of the upper and lower process edges, and cannot fall in the space within 2mm height of the left and right process edges.

3.The conductive copper foil in the process side should be as wide as possible. Lines less than 0.4mm need to be reinforced with insulation and abrasion-resistant treatment, and the lines on the outermost side are not less than 0.8mm.

4.The stamping holes or V-grooves can be used to connect the craft side to the PCB. Generally, V-grooves are used.

5.There should be no pads or through holes on the side of the process.

6.A single board with an area greater than 80 mm² requires the PCB itself to have a pair of parallel process edges, and there is no physical entry of components above and below the process edge.

7.The width of the craft side can be appropriately increased according to the actual situation.