PCB drawing board engineers have an unshirkable responsibility!

The situation that is laid out is not alarmist. The reason is that there are still many factors to consider when laying out PCBs, such as electrical performance, process route, safety requirements, EMC impact, etc. Among the factors considered, electrical is the most basic. However, EMC is the most difficult to understand. The bottleneck of many projects is EMC. The following is the sharing of PCB layout and EMC from the 22nd direction.

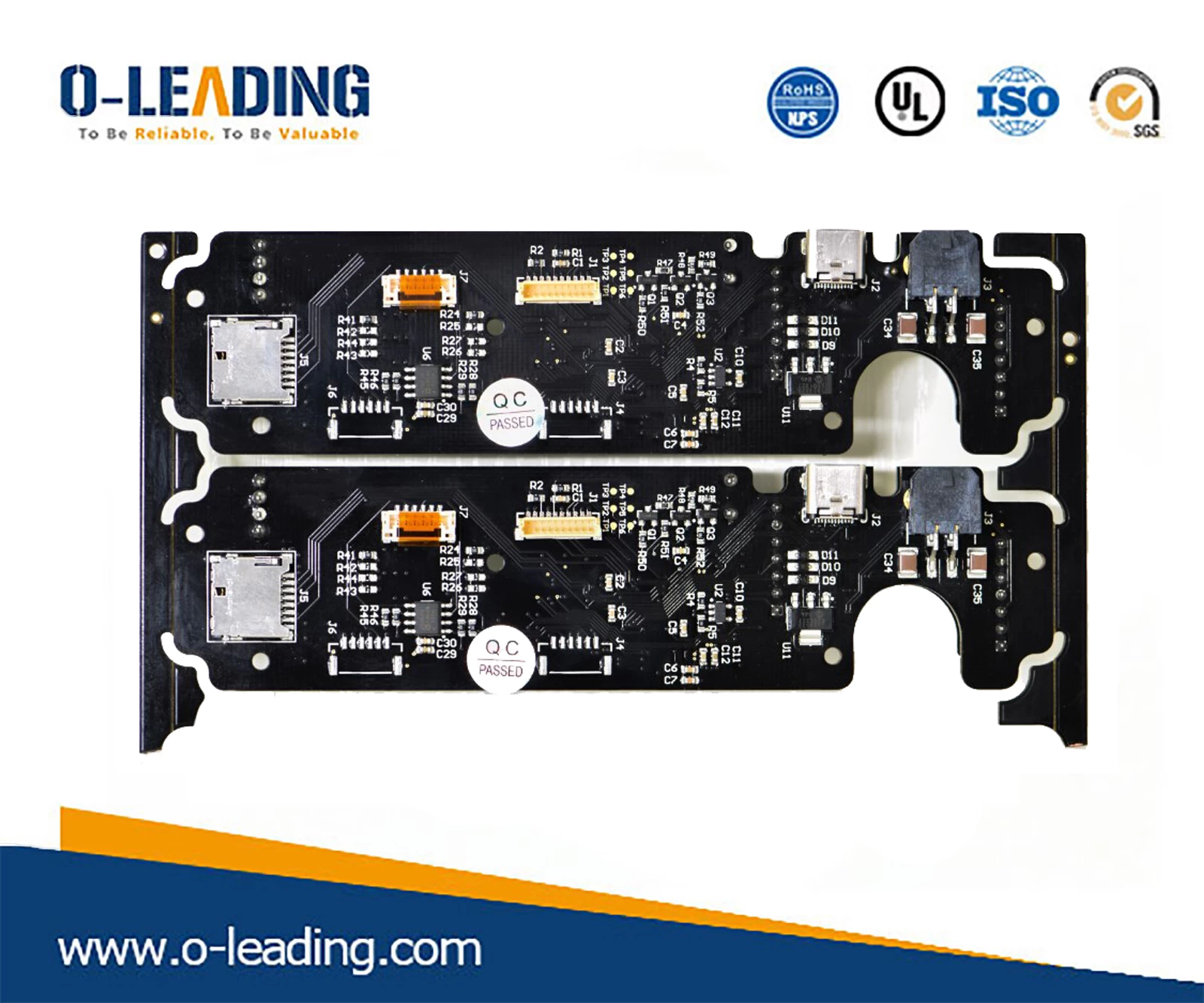

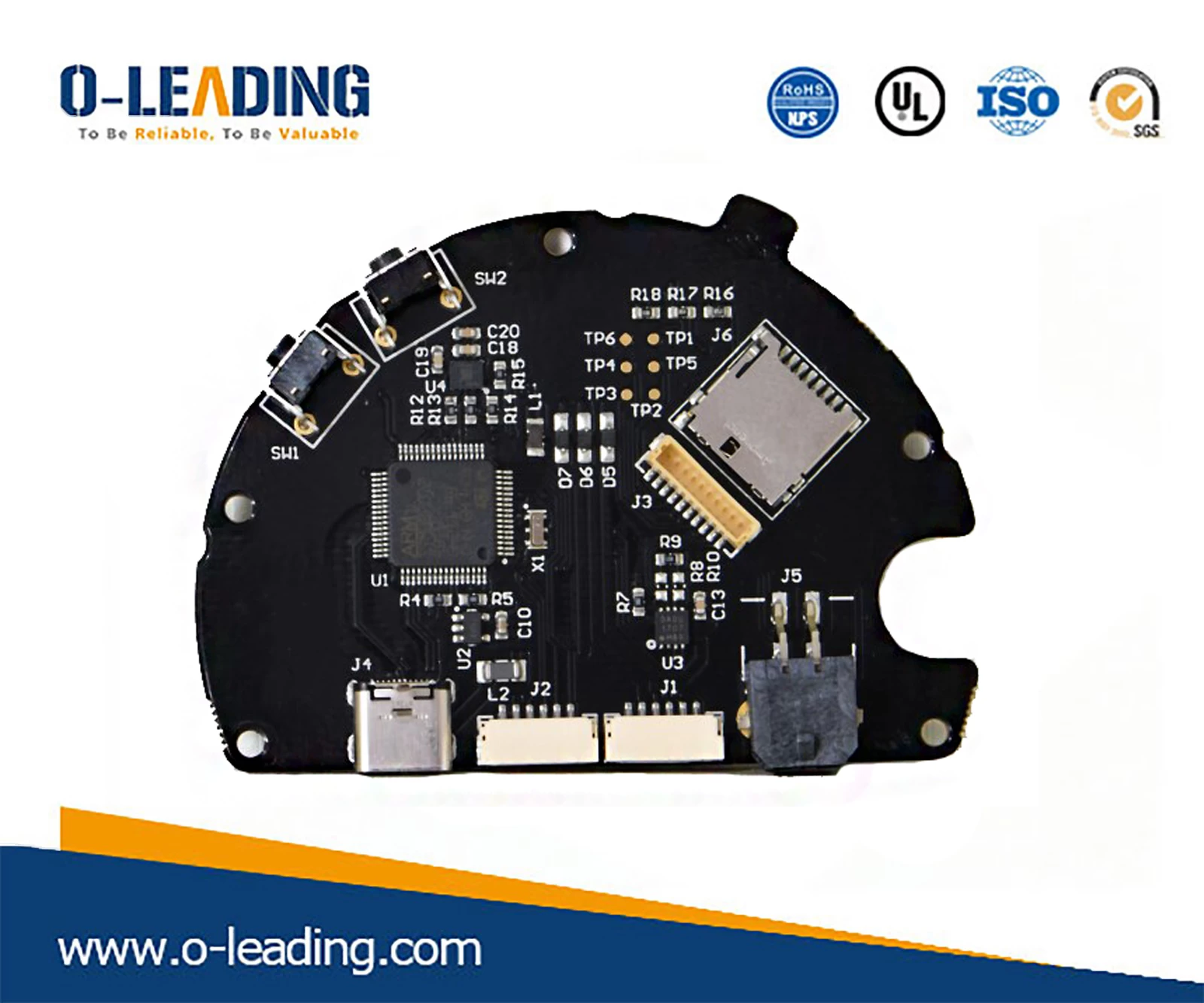

Nelco PCB factory china.

PCB design and EMC

1. The impact of the PCB loop on EMC is very important, such as the flyback main power loop. If it is too large, the radiation will be very poor.

2. Filter routing effect, the filter is used to filter out interference, but if the PCB trace is not good, the filter may lose its effect.

3. The structural part, the grounding of the heat sink design will affect, the grounding of the shielded version, etc.;

4. The sensitive part is too close to the source of the interference. For example, the EMI circuit is close to the switch tube, which will inevitably lead to poor EMC and a clear isolation area.

5. RC absorption loop routing.

6.Y capacitor grounding and routing, and the location of the Y capacitor is also very important!

One-stop Turnkey PCB & PCBA Manufacturing.

PCB design preparations:

1. Appearance structure size, including positioning hole, air flow direction, input and output socket, need to match the customer system, also need to communicate with the customer on the assembly problem, limit height and so on.

2. Safety certification, which kind of certification is made for the product, and where to make the basic insulation creepage distance should be enough, and where to strengthen the insulation to keep enough distance or slot.

3. Package design: There are no special periods, such as custom package preparation.

4. Process route selection: single-panel double-panel selection, or multi-layer board, based on the schematic and board size, cost and other comprehensive evaluation.

5. Other special requirements of the customer.

The structural process is relatively more flexible, the safety regulations are still relatively fixed parts, what certification is done, what safety standards have been passed, and of course there are some safety regulations that are common to many standards, but there are also some special products such as medical treatments that are more demanding.