- Contact Us

-

TEL: + 86-13428967267

FAX: + 86-4008892163-239121

+ 86-2028819702-239121

Email: sales@o-leading.com Contact Now

Contact Now

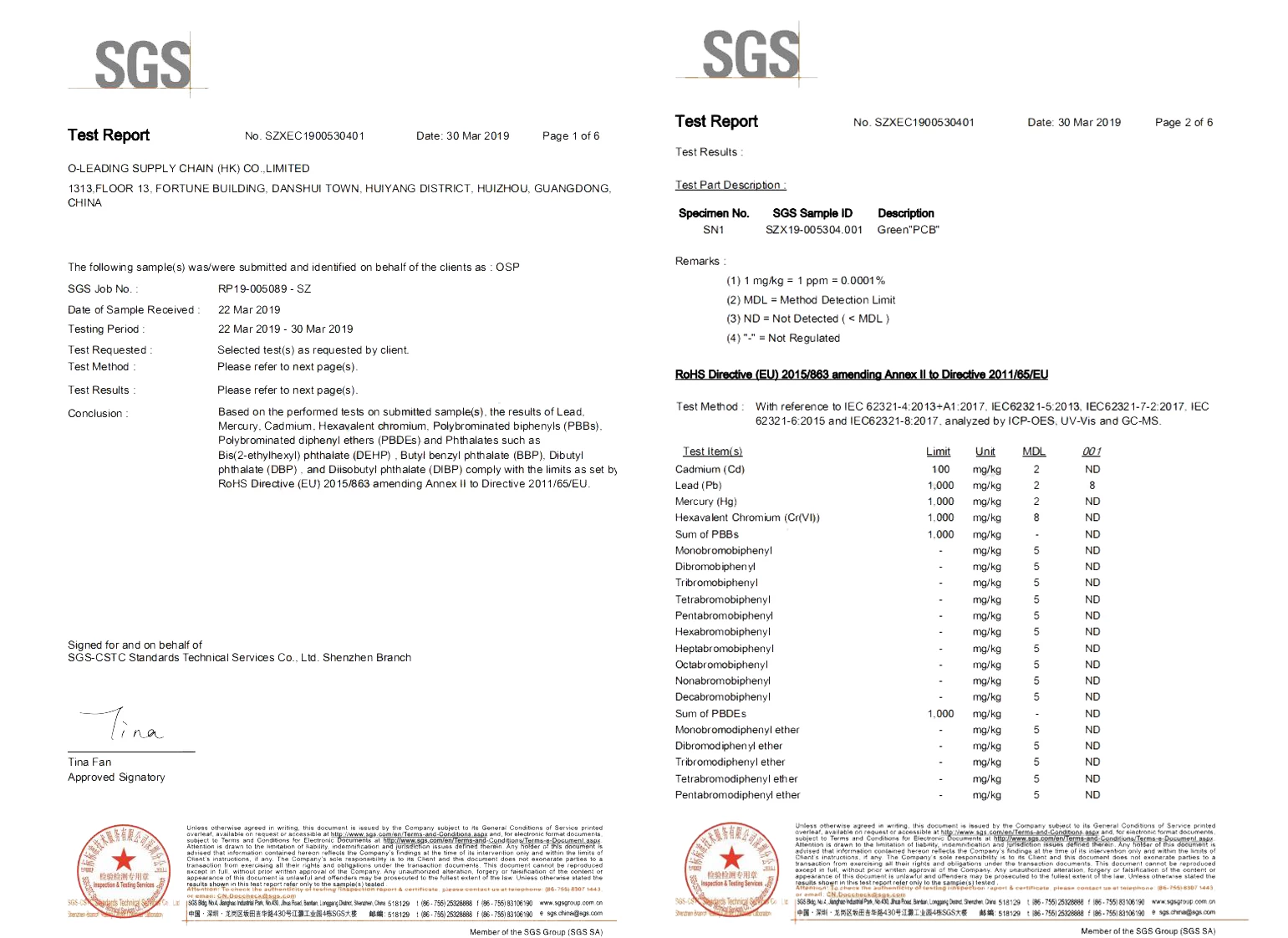

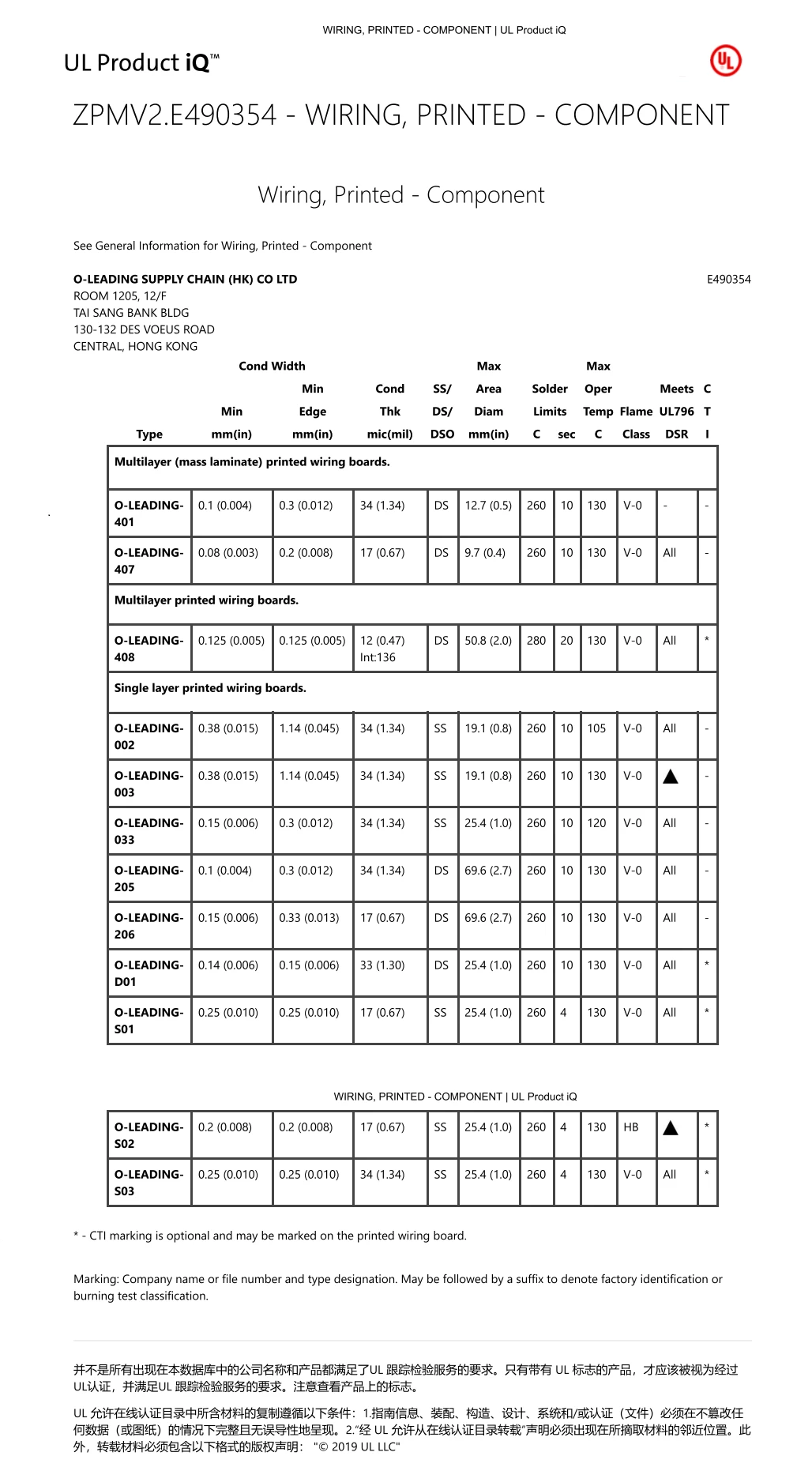

- Certifications

-

- Subscribe

-

Get email updates on new products

- New Products

-

Faster Networking Multi-Media Capability Powerful Processor Completely Upgraded Raspberry Pi 4 Model B 4GB RAM

AC DC Power Supply 110V 220V to 5V 700mA 3.5W Switching Switch Buck Converter, Regulated Step Down Voltage Regulator Module

China Top 10 Electronic Power Pcba Suppliers, Printed Circuit Board Pcba Power Assembly Manufacturer, Service PCBA Power Factory

Fast delivery PCB One Stop Service Circuit Board Manufacture PCB Assembly PCBA PCB receiver control board

SMT OEM PCB Manufacturer PCBA Service PCB Assembly Electronics Printer Control Sanitise Dispense Sensor Board

China Custom Multilayer PCB Board Service Half Plated Hold Wifi Module Small BGA Manufacturing Design

China Huizhou OEM Fast Lead Time Electronic PCB Board SMT Assembly PCBA Printed Circuit Board Manufacturer

China Electronic Circuit Board PCB Assembly Board customized SMT PCBA fabricatio Printed Circuit Board

Factory Price 0.2 6mm Thickness Electronic Hardware Plating Circuit Board,Double Side Pcb Hard Gold Board Manufacturer

PCB Assembly in China, Graphics adapter board, your one stop provider of PCB&PCBA, SMT production line, Apply for Bitcoin coin machine

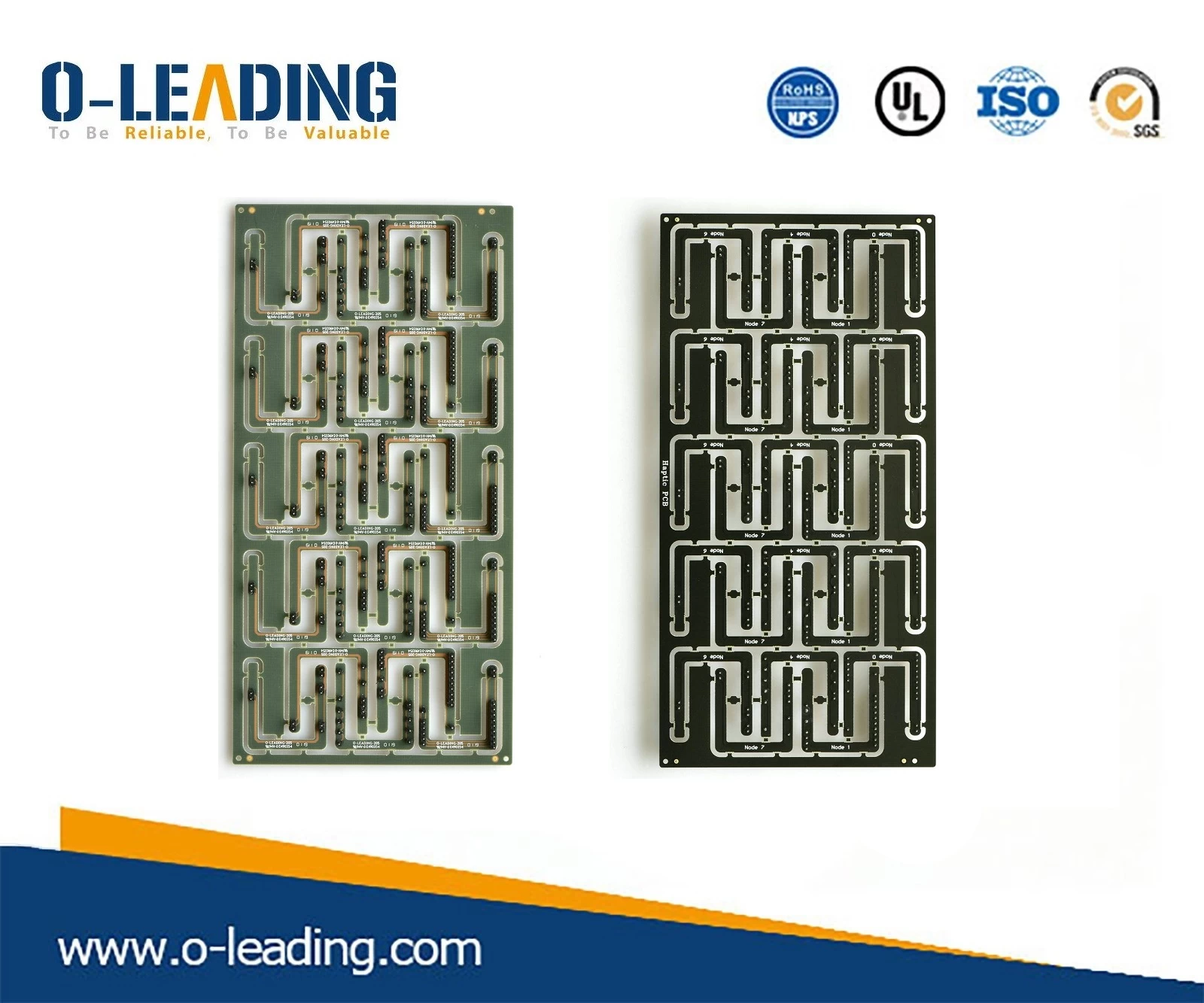

- 1. PCB P/N:: 25953685

- 2. Material: fr-4 tg130

- 3. On-board CCS: 1, 6 mm

- 4. Copper UK: 35um

- 5. Smallest hole size: 1, 0 mm

- 6. No. From holes (PC): 285

- 7. Line w/s: 6/6mil

- 8. Control of the impedance. Y/N (tolerance%): n

- 9. Lead-free HAL layer

- 10. Stencils on the soldering mask: Green

- 11. One board Size: Dim x (mm): 56; Dim y (mm): 135

- 12. Special: PCBs with component

- Routing/Punch: CN

| Welcome to O-leading |

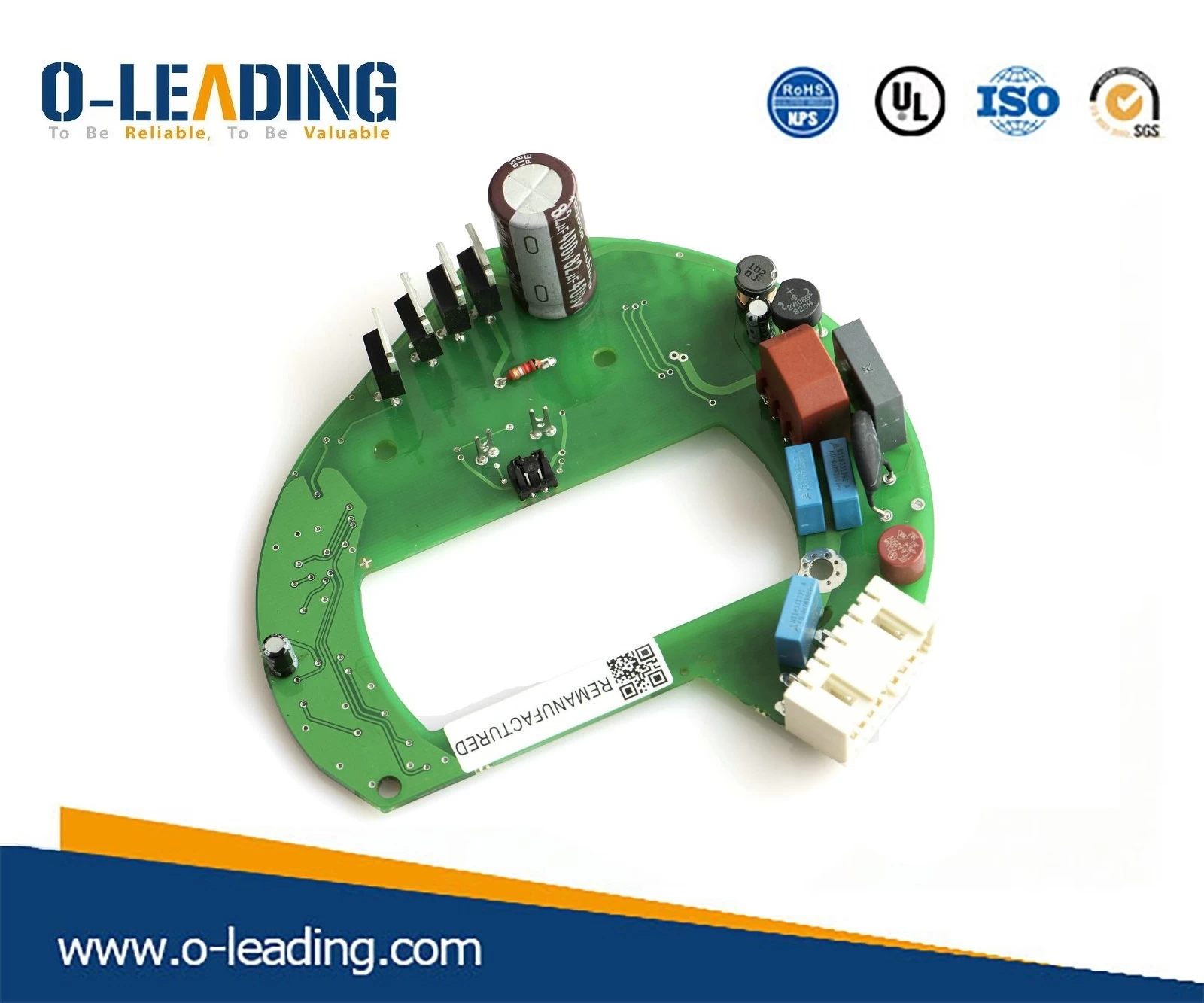

O-Leading strives to be your one stop solution partner in EMS supply chain, including PCB design , PCB fabrication and PCB assembly (PCBA).We provide some of the most advanced PCB technology, including HDI PCBs,multilayer PCBs, Rigid-Flexible PCBs.We can support from quick turn prototype to medium & mass Production. (GOLDEN FINGER BOARD supplier)

In general, our global customers are very impressed with our services:Rapid response, competitive price and quality commitment.Providing more valuable technical service and overall solution is the way O-leading forward.

Looking to the future, O-leading will concentrate on the innovation and development of electronics manufacturing technology as always, and make persistent efforts on PCB & PCBA one-stop service to provide first-class services and create more value for our customers.

PLEASE CLICK THESE FOR MORE INFORMATION:Ceramic PCB manufacturer china

| Product Description |

| PCB P/N | 25953685 |

| Material | fr-4 tg130 |

| On-board CCS | 1.6mm |

| copper UK | 35um |

| Smallest hole size | 1.0MM |

| No. of From holes (pcs) | 285 |

| line w/s | 6/6mil |

| Impedance control. Y / N (Tol %) | N |

| Surface Finishing:Plated hard Gold, Au |

HASL-LF Sn:1-40um. |

| Lead-free HAL layer | |

| Solder Mask Silkscreen | Green |

| Single board size | Dim X (mm):343.40;Dim Y (mm):312.46 |

| Panelisation | Dim X (mm): 56 ;Dim Y (mm): 135 |

| Special |

PCBs with component |

| Routing/Punching | CN |

| Our Team |

| Certifications |

| Packaging & Delivery |

| Process Capability |

PCB Production Capabilities

Layer Count: 1Layer-32Layer

Finished copper thickness: 1/3oz-12oz

Min Line width/spacing internal: 3.0mil/3.0mil

Min Line width/spacing external: 4.0mil/4.0mil

Max Aspect Ratio: 10:1

Board thickness: 0.2mm-5.0mm

Max Panel size(inches): 635*1500mm

Minimum Drilled Hole Size: 4mil

PIated Hole Tolerance: +/-3mil

BIind/Buried Vias (AII Types): YES

Via Fill(Conductive,Non-Conductive): YES

Base Material: FR-4,FR-4high Tg.Halogen free material,Rogers,Aluminium base,Polyimide,

Layer Count: 1Layer-32Layer

Finished copper thickness: 1/3oz-12oz

Min Line width/spacing internal: 3.0mil/3.0mil

Min Line width/spacing external: 4.0mil/4.0mil

Max Aspect Ratio: 10:1

Board thickness: 0.2mm-5.0mm

Max Panel size(inches): 635*1500mm

Minimum Drilled Hole Size: 4mil

PIated Hole Tolerance: +/-3mil

BIind/Buried Vias (AII Types): YES

Via Fill(Conductive,Non-Conductive): YES

Base Material: FR-4,FR-4high Tg.Halogen free material,Rogers,Aluminium base,Polyimide,

Heavy Copper

Surface finishes: HASL,OSP,ENIG,HAL-LF,lmmersion silver,lmmersion Tin,Gold fingers,Carbon ink

SMT Production Capabilities

PCB Material: FR-4,CEM-1,CEM-3,Aluminum-based board

Max PCB size: 510x460mm

Min PCB size:50x50mm

PCB Thickness:0.5mm-4.5mm

Board thickness:0.5-4mm

Min Components size: 0201

Standard chip size component: 0603 and larger

Component max height:15mm

Min lead pitch: 0.3mm

Min BGA ball pitch:0.4mm

Placement precision: +/-0.03mm

PCB Material: FR-4,CEM-1,CEM-3,Aluminum-based board

Max PCB size: 510x460mm

Min PCB size:50x50mm

PCB Thickness:0.5mm-4.5mm

Board thickness:0.5-4mm

Min Components size: 0201

Standard chip size component: 0603 and larger

Component max height:15mm

Min lead pitch: 0.3mm

Min BGA ball pitch:0.4mm

Placement precision: +/-0.03mm