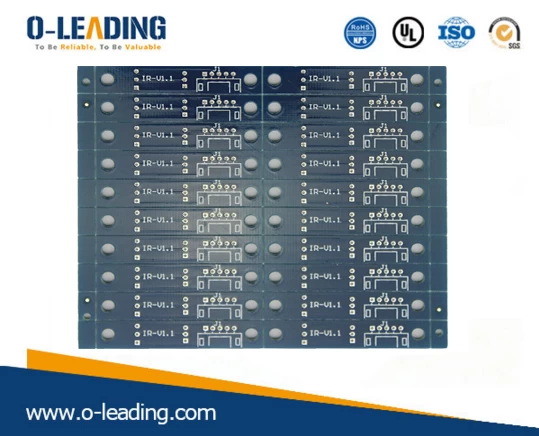

How to reflow soldering SMT red plastic double-sided PCB patch!

One is double-sided solder paste, one side of solder paste, one side of red plastic. 3D printer PCB supplier.

Both processes are almost always welded on one side and then welded on the other side. Because the melting temperature after curing of solder paste or red glue is greater than the temperature of reflow soldering, it will not be lost due to temperature. Printed circuit boards supplier.

However, the solder paste surface can no longer be wave soldered, but the red rubber surface can be wave soldered.

Incoming material inspection-->PCB A-side silk screen solder paste (point paste glue) --> patch --> drying (curing) --> A surface reflow soldering --> cleaning --> flap -- >PCB B-side silk screen solder paste (point paste glue) --> patch --> drying --> reflow soldering (preferably only for B side --> cleaning --> detection --> repair). China pcb manufacturers.

This process is suitable for use when mounting large SMDs such as PLCC on both sides of the PCB.

First, the solder paste is printed on the A side of the board, and the SMT components are pasted and then soldered into the furnace. Then, the solder paste is printed on the B side, and the components are pasted and soldered again. At this time, the B side of the board faces upward, and the soldering is completed under normal temperature control; the A side faces downward, the heated temperature is low, and the soldered components do not fall off the board.