Analysis on PCBA fault phenomenon

(1)Failure phenomena of PCBA (internal or surface) during the manufacturing process: such as bursting, delamination, surface excess, ion migration, and chemical corrosion (rust).

(2) Various failure modes and fault manifestations on PCBA during user service: such as solder joints, brittle breaks, micro-tissue degradation in solder joints, and reliability variations.

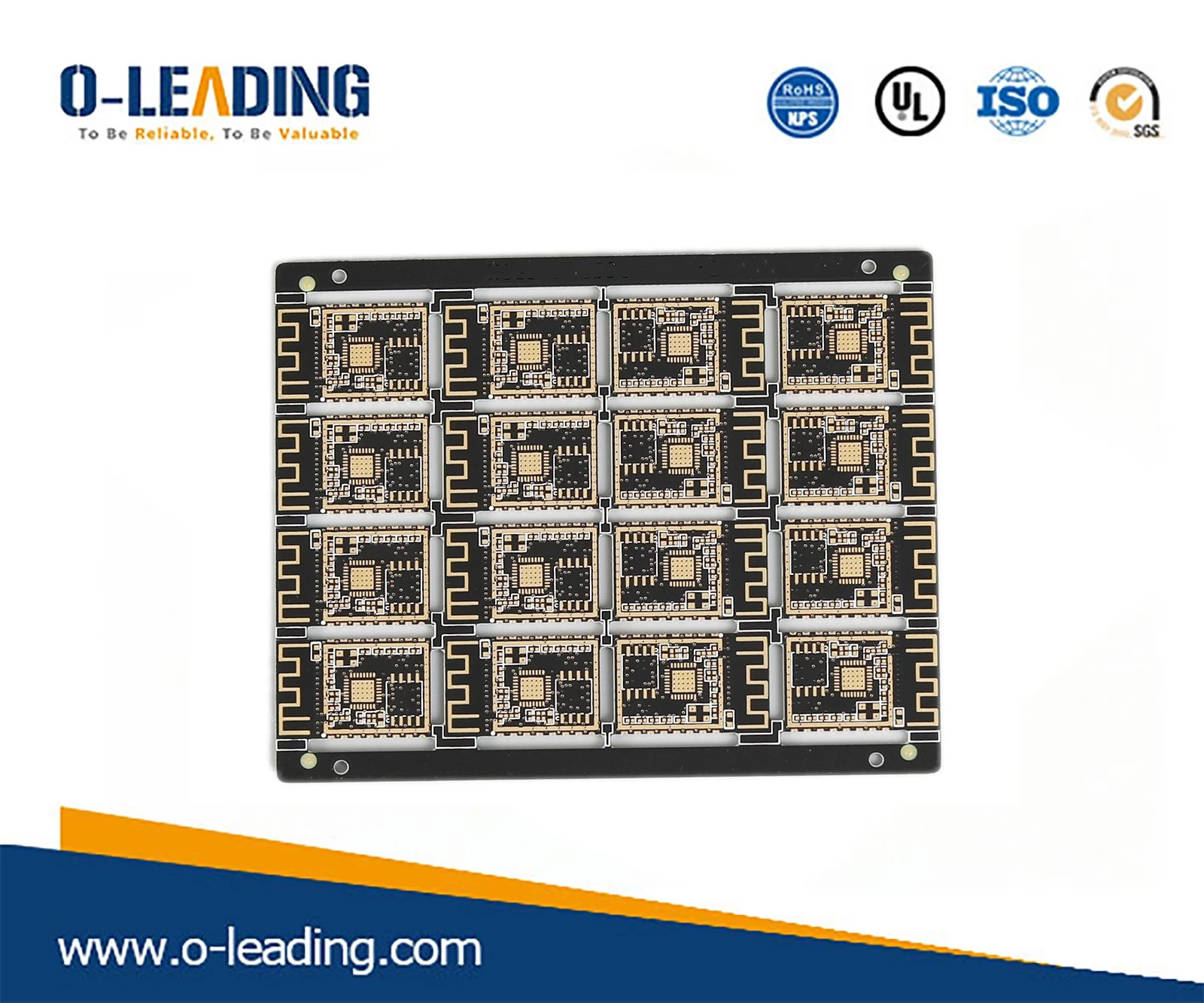

High Tg PCB manufacturer china.

Purpose of failure analysis

Fault analysis is the process of determining the cause of the fault, collecting and analyzing the data, and summarizing the mechanisms that eliminate the failure that caused the failure of a particular device or system.

The main purpose of fault analysis is to:

1 Find out the cause of the fault;

2 trace the adverse factors in process design, manufacturing process, and user service;

3 Propose corrective actions to prevent recurrence of the failure.

Through the results accumulated by fault analysis, the process design is continuously improved, the product manufacturing process is optimized, and the usability of the product is improved, thereby achieving the purpose of comprehensively improving product reliability.

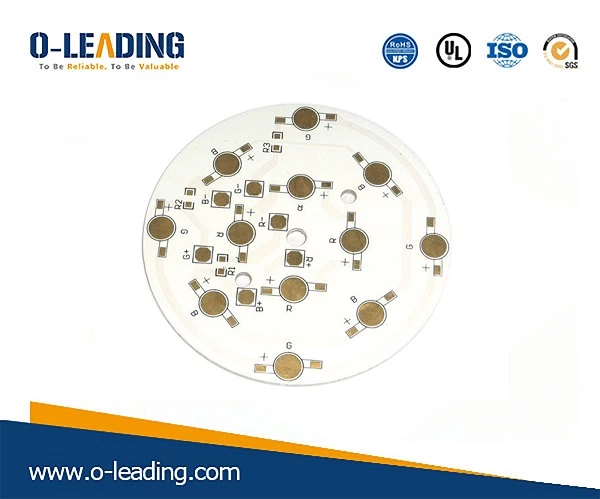

Aluminum PCB manufacturer china.

Levels and principles and methods of PCBA failure analysis

1. Level of failure analysis

In the production and application of electronic products, the control and analysis of PCBA and solder joint failure are basically the same as the reliability control and analysis methods of other systems, as shown in Figure 3.

2. The principle of failure analysis - the basis of mechanism reasoning

1 site information;

2 retest (failure mode confirmation) result analysis;

3 the failure mechanism of the specific process and structure of the object;

4 failure mechanisms related to specific environments;

5 relationship between failure mode and failure mechanism;

6 Long-term accumulation of knowledge and experience.