Why are PCB multilayer boards even layers?

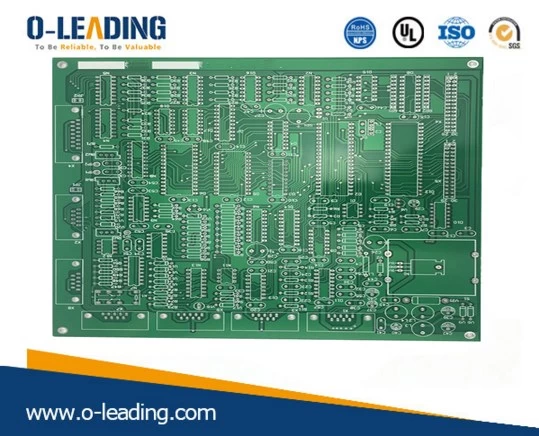

There are single-sided, double-sided,and multi-layer PCB boards.Among them,the number of layers of multilayer boards is not limited.Currently,There are already more than 100 layers of PCB,and common multilayer PCB are four-layer and six-layer boards.

Then why do you have such a question as "Why are PCB multilayer boards even layers?" Relatively speaking,PCB with even layers are indeed more advantageous than PCB with odd layers.

1.Low cost

Because of one less layer of dielectric and foil, the cost of raw materials for odd-numbered PCB is slightly lower than for even-numbered PCB. However, the processing cost of the odd-layer PCB is significantly higher than that of the even-layer PCB. The processing cost of the inner layer is the same, but the foil / core structure significantly increases the processing cost of the outer layer.

Odd-layer PCB need to add a non-standard stacked core layer bonding process to the core structure process. Compared with the nuclear structure, the production efficiency of the factory in which the foil is added outside the nuclear structure will decrease. Before laminating and bonding, the outer core requires additional processing, which increases the risk of the outer layer being scratched and etched incorrectly.

2.balanced structure to avoid bending

The best reason for not designing PCB with odd layers is that circuit boards with odd layers are easily bent. When the PCB is cooled after the multi-layer circuit bonding process, different lamination tensions of the core structure and the foil-laminated structure may cause the PCB to bend. As the thickness of the circuit board increases, the risk of bending of a composite PCB with two different structures increases. The key to eliminating circuit board bending is to use a balanced stack. Although a certain degree of bent PCB meets the requirements of the specification, subsequent processing efficiency will decrease, resulting in increased costs. Because special equipment and technology are required for assembly, the accuracy of component placement is reduced, which will damage the quality.

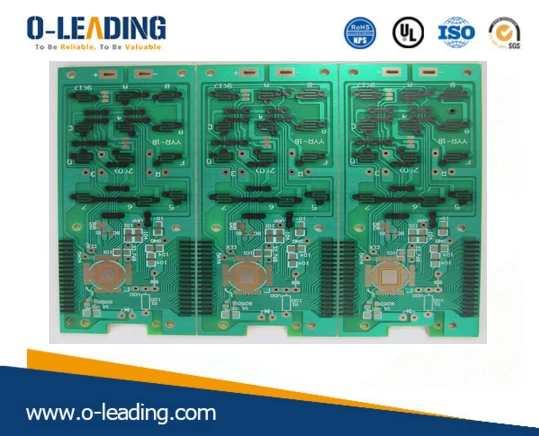

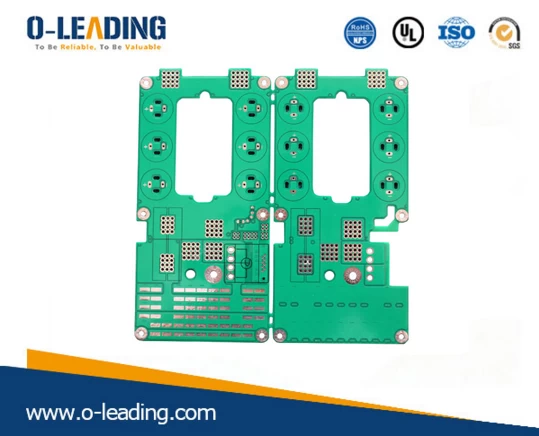

Multilayer pcb manufacturer china

To put it more easily, the four-layer board is better controlled than the three-layer board in the PCB process technology, mainly in terms of symmetry. The warpage of the four-layer board can be controlled below 0.7% (IPC600 standard), but When the size of the three-layer board is large, the warpage will exceed this standard. This will affect the reliability of the SMT patch and the entire product. Therefore, ordinary designers do not design odd-layer boards. Designed as pseudo-even layers, that is, 5 layers are designed as 6 layers, and 7 layers are designed as 8 layers.

Based on the above reasons, most of PCB multilayer boards are designed with even layers and fewer with odd layers.