How to improve PCB anti-interference ability?

1. The following systems should pay special attention to anti-electromagnetic interference:

(1) A system in which the microcontroller clock frequency is particularly high and the bus cycle is particularly fast.

(2) The system contains high-power, high-current drive circuits, such as spark relays and high-current switches.

(3) System with weak analog signal circuit and high-precision A / D conversion circuit.

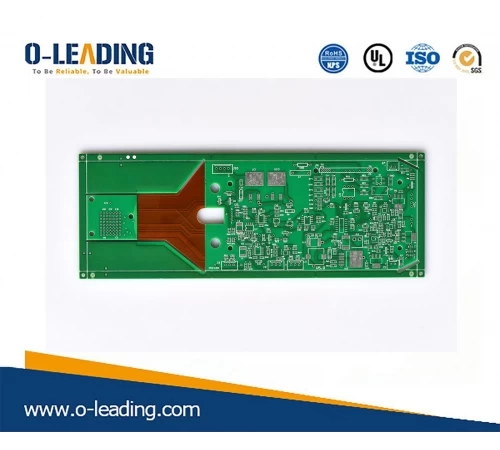

Lead free HAL wholesales china

2. Take the following measures to increase the anti-electromagnetic interference capability of the system:

(1) Use a low-frequency microcontroller:

The use of a microcontroller with a low external clock frequency can effectively reduce noise and improve the anti-interference ability of the system. For square and sine waves of the same frequency, the high-frequency components in a square wave are much more than those of a sine wave. Although the amplitude of the high-frequency component of the square wave is smaller than the fundamental wave, the higher the frequency, the easier it is to be emitted as a noise source. The most influential high-frequency noise generated by the microcontroller is about three times the clock frequency.

(2) Reduce distortion in signal transmission

The microcontroller is mainly manufactured using high-speed CMOS technology. The static input current of the signal input end is about 1mA, the input capacitance is about 10PF, the input impedance is quite high, and the output end of the high-speed CMOS circuit has a considerable load capacity, that is, a relatively large output value. If the long line is led to the input end with relatively high input impedance, the reflection problem is very serious, it will cause signal distortion and increase system noise. When Tpd> Tr, it becomes a transmission line problem, and the problems of signal reflection and impedance matching must be considered. The delay time of the signal on the printed board is related to the characteristic impedance of the leads, that is, the dielectric constant of the printed circuit board material. It can be roughly considered that the transmission speed of signals on the printed circuit board leads is about 1/3 to 1/2 of the speed of light. The Tr (standard delay time) of commonly used logic telephone components in a system composed of a microcontroller is between 3 and 18 ns. On the printed circuit board, the signal passes a 7W resistor and a 25cm long lead, and the delay time on the line is approximately 4-20ns. In other words, the shorter the lead of the signal on the printed circuit, the better, and the longest should not exceed 25cm. And the number of vias should be as small as possible, preferably not more than two.

When the rise time of the signal is faster than the delay time of the signal, it must be processed according to fast electronics. At this time, it is necessary to consider the impedance matching of the transmission line. For the signal transmission between the integrated blocks on a printed circuit board, it is necessary to avoid the situation of Td> Trd. The larger the printed circuit board, the faster the system cannot be too fast.

Use the following conclusions to summarize a rule for printed circuit board design:

The signal is transmitted on the printed board and its delay time should not be greater than the nominal delay time of the device used.