Problems that should be noticed in the success or failure of PCB design 1

o-lead

o-leading.com

2018-05-21 15:10:15

In PCB design, Design Rule design rules are the key to the success or failure of a PCB design. All designer's intentions, the functional embodiment of the design are driven and realized through the soul of design rules. The meticulous definition of the rules can help designers get the job done in PCB layout and wiring, save engineers a lot of energy and time, help designers achieve excellent design intent, and greatly facilitate the design work.

After the design data is transferred from the schematic phase to the PCB design phase, when designing the PCB design layout, it is necessary to define the design rule Design Rule in advance. Subsequent entire PCB designs need to follow the rule definition. Including the most basic electrical rules (pitch, short-circuit open circuit), wiring rules (line width, trace style, via pattern, fanout, etc.), plane rules (power ground plane connection, copper connection); and others Common auxiliary rules such as layout rules, manufacturing rules, high-speed design rules, signal integrity rules, etc. After the rule-driven design is completed, you can also conduct a rule check Design Rule Check to revisit your design to see if there is any violation of the rule and improve and perfect it. Ultimately, we design an outstanding work that fully meets the definition of the rules and satisfies the design intent.

What are the accuracy requirements of the PCB manufacturing process?

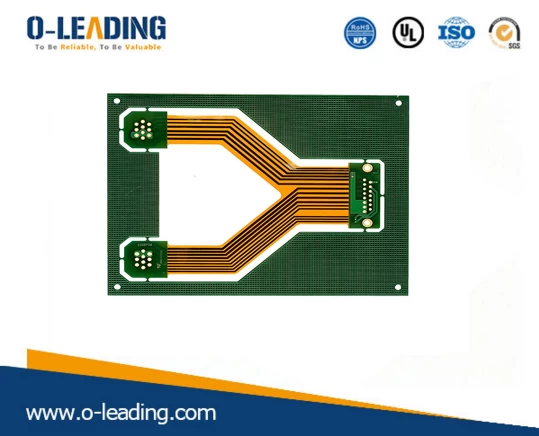

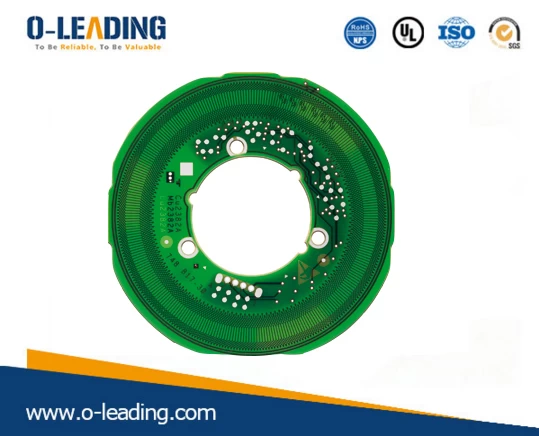

The following figure shows the process requirements of a PCB board manufacturer. Including the number of circuit board layers, thickness, aperture, minimum line width, copper thickness and other basic parameters; also includes special requirements such as sheet type, surface treatment, and special processing. In general, when PCB is processed, the proofing process is divided into tests, and the final shaped batch product is processed. For designers, what is practical and needs to be strictly followed is the process requirements for mass product processing.

The most basic and most important of the manufacturing(Pcb prototype manufacturer china) requirements related to manufacturing accuracy is the line width and minimum aperture. That is, the processing plant can handle the smallest and finest line width and the smallest hole. If the line width does not meet the requirements in the design, it will not be processed correctly if it is too thin. Line spacing accuracy also affects whether the text pattern on the silk screen is clear. If the aperture is too small, there is no corresponding drill bit to support it. The size of the drill bit corresponding to the smallest aperture also affects the tolerances of various types of plate-shaped cutting such as mechanical holes and mounting holes.