PCBA cold welding analysis

The phenomenon of the virtual welding phenomenon is complicated, the influence is wide, and the concealment is large, so the loss caused is also large. In actual work, in order to find a virtual solder joint, it often takes a lot of manpower and material resources, and the radical measures involve a wide range, and it is not easy to establish long-term stable solutions. Therefore, the problem of virtual soldering has always been the focus of attention in the electronics industry.

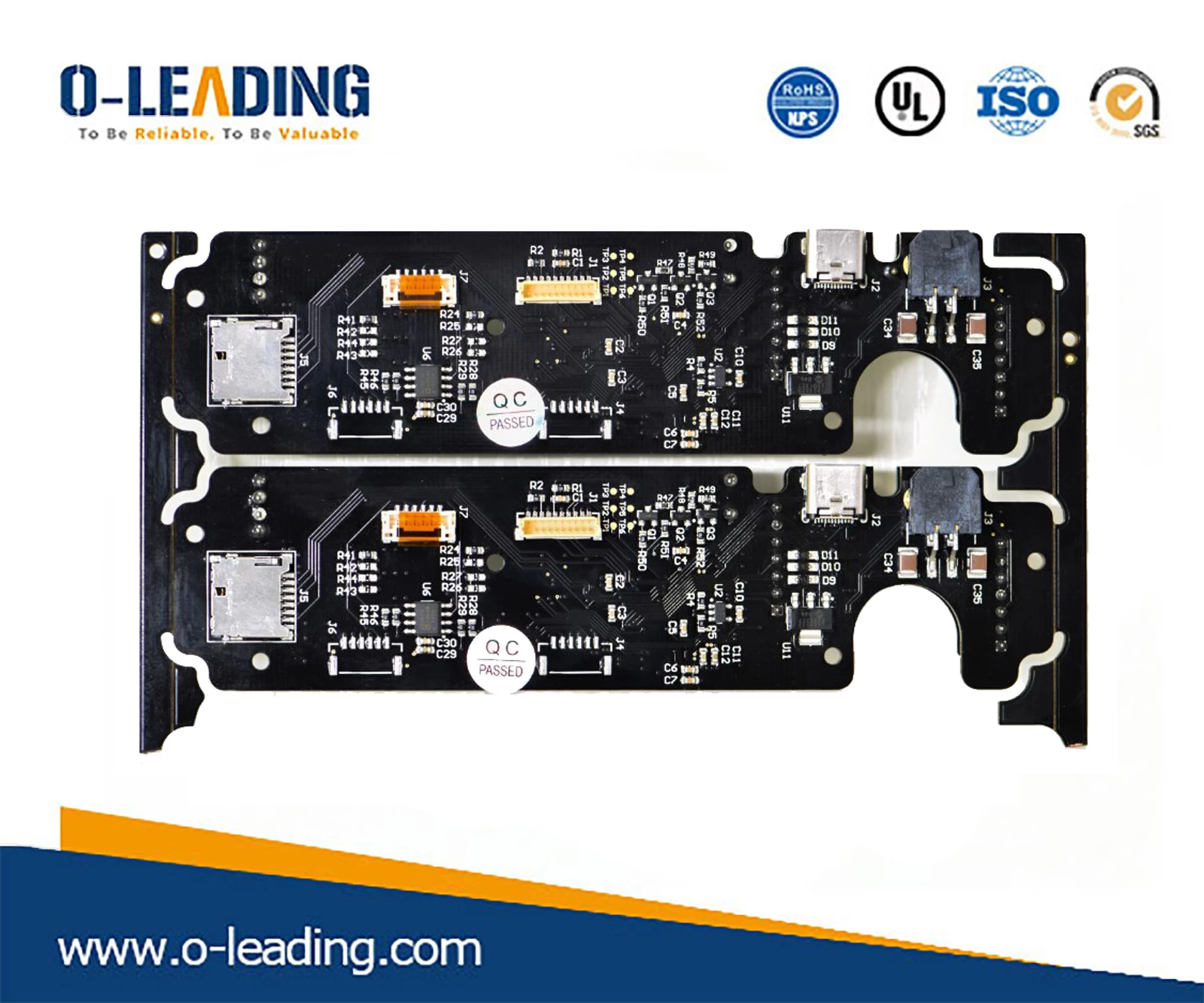

Immersion Tin supplier china.

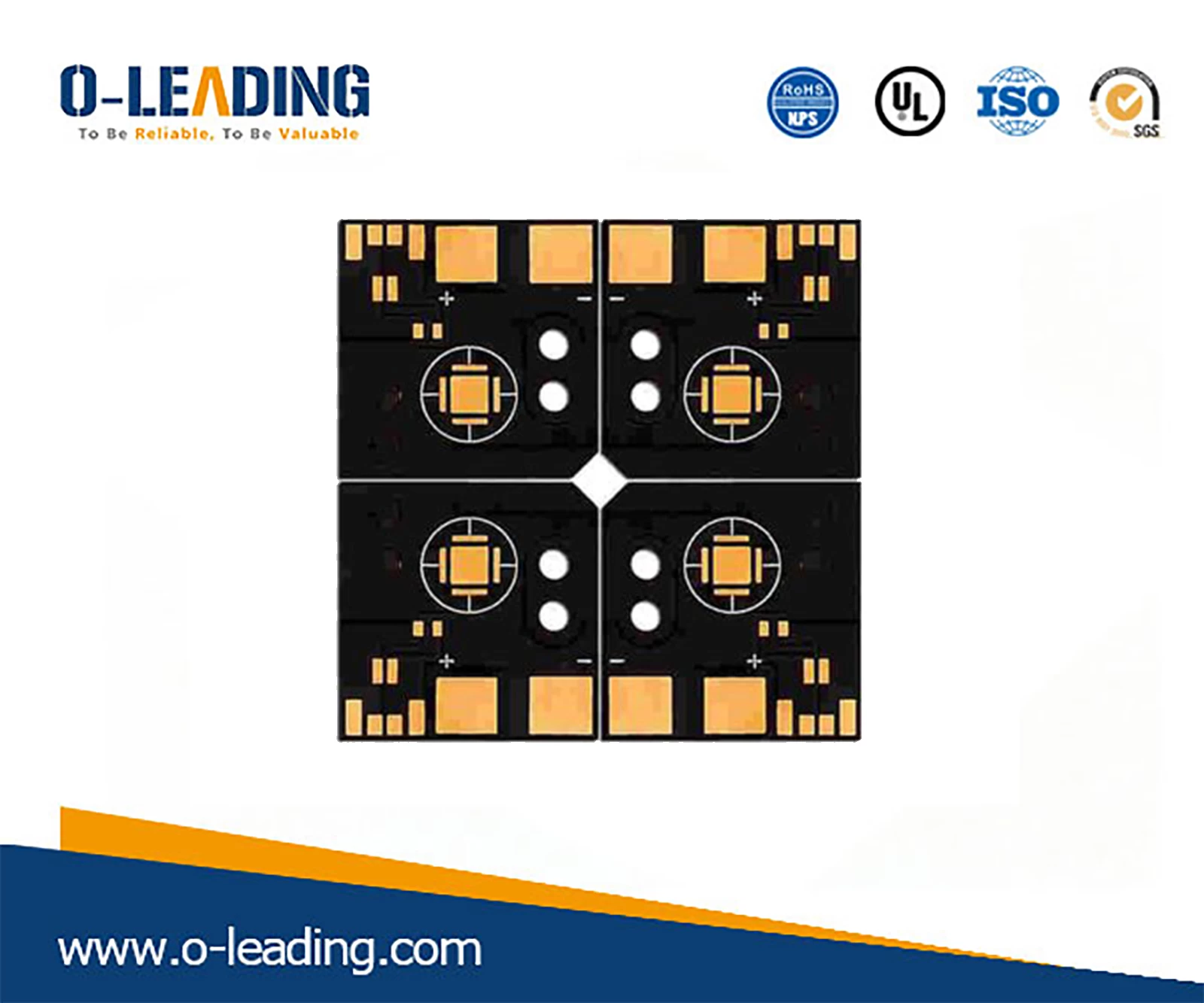

In modern electronic assembly soldering, cold soldering is a high-profile defect in the reflow soldering of ≤0.5mmμBGA and CSP packaged chips. In such devices, due to the concealment of the soldered portion, heat is difficult to transfer to the solder ball solder joint portion, so the probability of cold soldering is higher than that of the solder joint. PCB with Copper Filling wholesales.

However, since cold welding is very similar to the virtual solder in the performance of defects, it is often misjudged as a false solder and is masked. When dealing with the problem that the circuit function is invalid due to the cold welding phenomenon, it is often treated by the virtual welding, and the result is that the effect is very small.

The quality consequences of cold welding and virtual welding are similar, but the mechanism of formation is not the same. It is difficult to distinguish between cold welding and cold welding without visual image discrimination.

They are difficult to fully expose during the production process, and often require users to use them for a period of time (several days, long months or even one year) before they can be exposed. Therefore, not only the impact is extremely bad, but the consequences are also serious.