Which way can PCBA sub-board replace manual, with minimal stress and more reliable quality?

Secondly, it can control the inventory, reduce the waste in the production process, and the loss caused by the transshipment. The introduction of high-precision automation equipment (SMT fully automatic milling cutter PCBA sub-board machine) by our industry electronics factory is also to reduce manual participation and improve product quality and consistency.

10 years ago, the development of SMT patch and DIP plug-in soldering manufacturing industry is not as fast as today. The labor cost is relatively low. There are certain technical barriers to automation equipment technology. The relative cost is high. Most factories are pursuing short-term. In the case of the interests, choose a low labor cost model.GLOBAL SUCCESS PCB supplier.

With the maturity of automation technology, labor costs have increased year by year. Under the premise of the decline of electronic products, automation is one of the most effective means to reduce costs and increase profits.

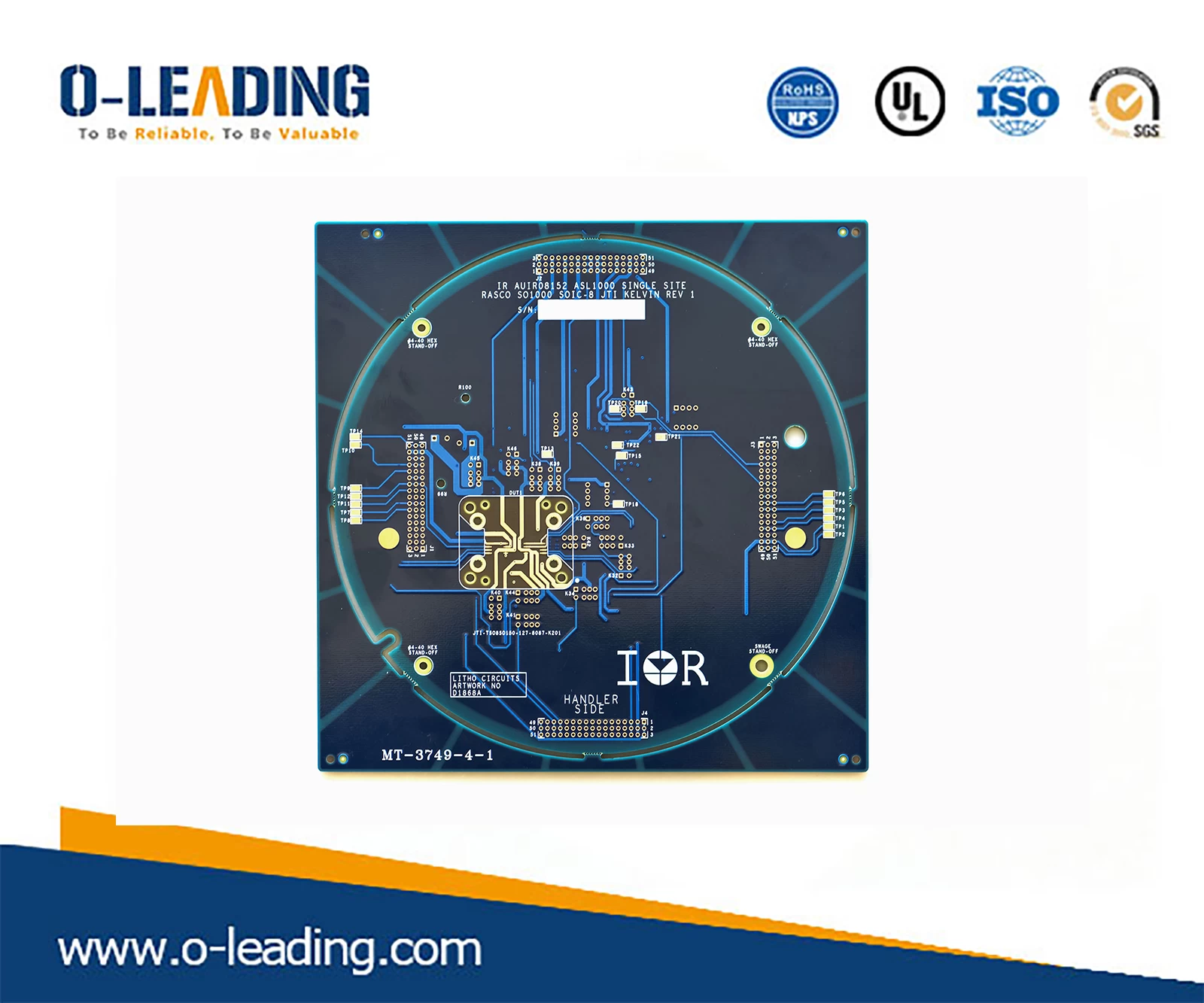

At present, all kinds of high-tech industries continue to develop and grow, and the circuit board industry is booming. However, the rapid development of the electronics industry has made equipment manufacturers face more and more new challenges. The Yilian PCBA circuit board automatic board splitter has maintained its leading position in the market with excellent precision, speed and process stability.Ceramic Flash Gold wholesales.

In the global 5G commercial pace is approaching, network construction and terminal replacement needs are accelerated! In the 5G era, all things connected, car electronics and auto-driving car electronics are expected to usher in high growth; in the future, 5G is too important! All of China Unicom's foundation is 5G. Cars, banks pay, clothing, food and shelter all need 5G, and many high-tech are built on 5G.

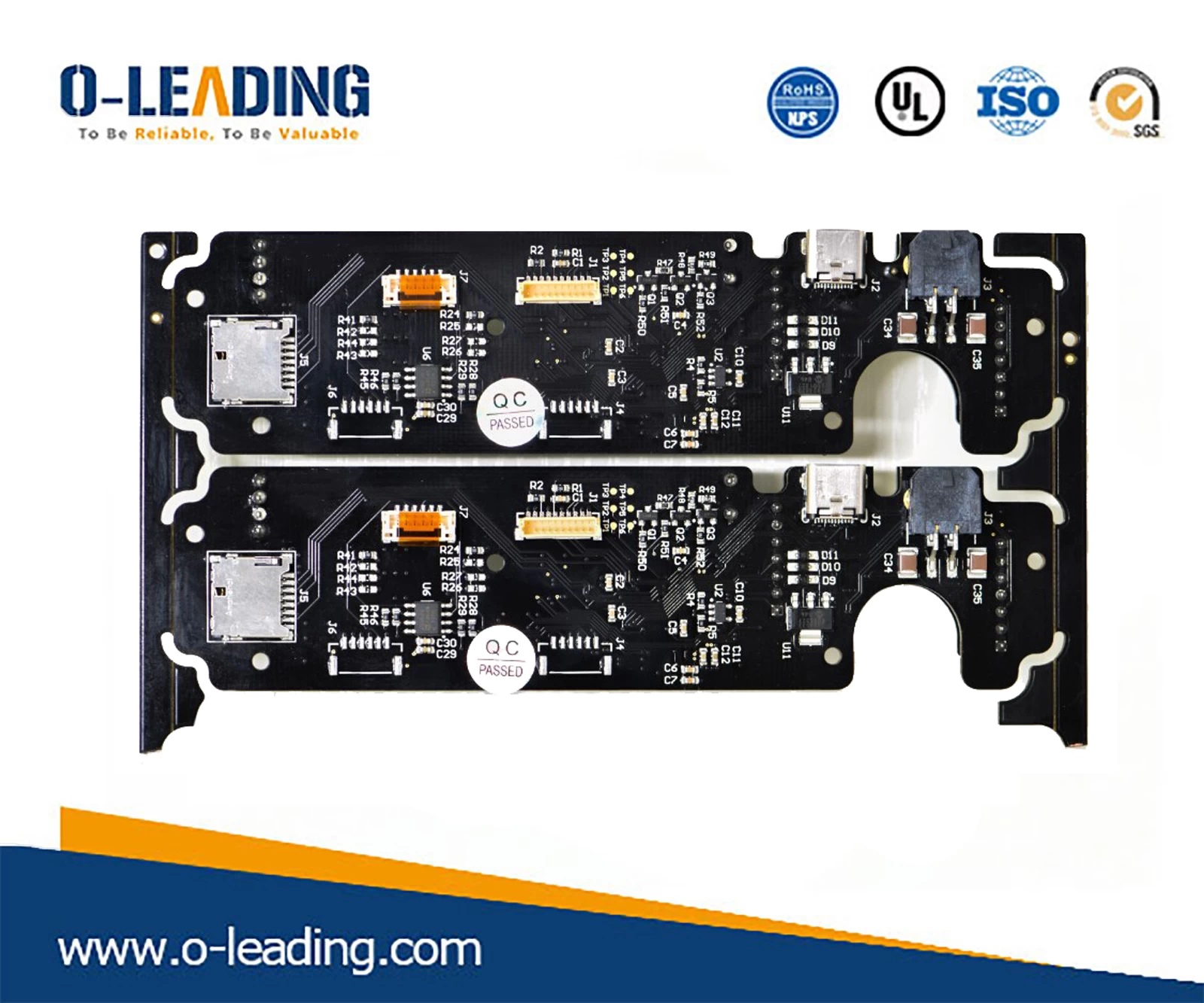

With the upgrading of smart phones and automotive electronics, EMS manufacturers must constantly improve their process technology and keep up with the trend to meet the demand for electronic products for the supporting supply chain.

For smart phones, thin and light, multi-functional and high-performance are long-term development trends, requiring EMS manufacturers to complete SMT placement process on smaller, multi-layered PCBs; to meet the requirements, EMS companies need not only introduce New equipment, new technology, to ensure the overall manufacturing capacity and advanced production technology, but also need to train professionals to develop, implement and manage new processes, all links are indispensable.