Main raw materials and types of FPC

The main raw materials are right: 1. base material, 2. cover film, 3. reinforcement, 4. other auxiliary materials.

1. Substrate

Adhesive substrate

Adhesive substrates are mainly composed of three parts: copper foil, adhesive and PI. There are two types of single-sided substrates and double-sided substrates. The material with only one side of copper foil is single-sided substrate, and the material with double-sided copper foil is double Surface substrate.

Glue-free substrate

The non-adhesive substrate is the substrate without the adhesive layer. Compared with the ordinary adhesive substrate, the middle adhesive layer is missing, and it is composed of only two parts: copper foil and PI, which is thinner than the adhesive substrate , Better dimensional stability, higher heat resistance, higher bending resistance, better chemical resistance and other advantages, now has been widely used.

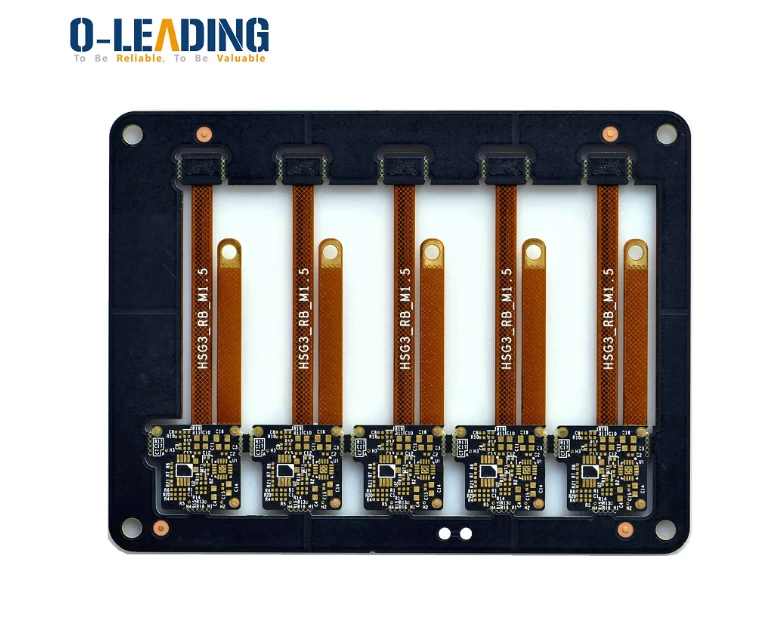

Rigid Flexible PCB supplier china

Copper foil: At present, the commonly used copper foil thickness has the following specifications, 10Z, 1/20Z, 1/3OZ, and now a thinner copper foil with a thickness of 1/4OZ is introduced, but this material is already being used in China, and ultra-fine Road (line width and line spacing of 0.05MM and below) products. With the increasing requirements of customers, materials of this specification will be widely used in the future.

2. Cover film

It is mainly composed of three parts: release paper, glue, and Pl. Finally, only glue and PI remain on the product. The release paper will be torn off during the production process and will not be used again (its role is to protect the glue with foreign matter).

3. Reinforce

It is a specific material used for FPC and used in a specific part of the product to increase the support strength and make up for the "soft" characteristic of FPC.

At present, the commonly used reinforcement materials are as follows:

FR4 reinforcement: The main components are glass fiber cloth and epoxy resin glue, the same as the FR4 material used in PCB

Steel sheet reinforcement: The composition is steel, which has strong hardness and support strength

PI reinforcement: Same as cover film, composed of three parts: P and release paper, except that the P| layer is thicker, and it can be produced from 2M to 9ML.

Multilayer FPC board with FR-4 stiffeners supplier

4. Other auxiliary materials

Pure glue: This adhesive film is a heat-curing acrylic adhesive film composed of protective paper/release film and a layer of glue. It is mainly used for layered boards, flexible and rigid boards, and FR-4 /Steel sheet reinforcement board, play a role in bonding.

Electromagnetic protective film: Pasted on the board surface for shielding.

Pure copper foil: only composed of copper foil, mainly used for hollow board production.

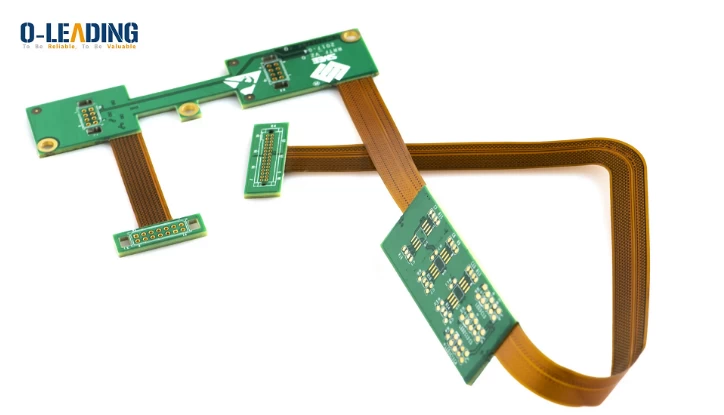

Chian High Quality custom FPCB/Flex PCB/FPC/Flexible PCB supplier

FPC type: FPC type has the following 6 types

A. Single panel: Only one side has wiring.

B. Double panel: There are lines on both sides.

C. Hollow board is also called window board (open window on finger surface)

D. Layered board: Weft on both sides (separate)

E. Multilayer boards: circuits with more than two layers

F. Rigid-flex board: a combination of soft board and hard board.