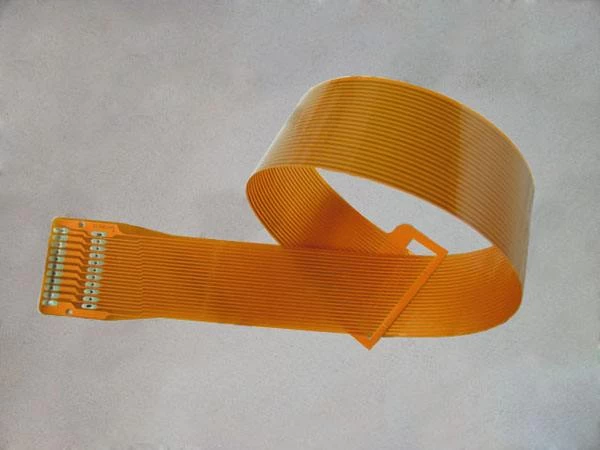

Flexbile Printed Circuit Manufacturer

Flexible Printed Circuit Board (FPC) has been widely used in a lot of areas: laptop, LCD panel, camera, DVD, automobile, outer space communication and military products. O-Leading's product targets on parts of mobile devices. We make full use of mature supply chain of Pearl River Delta and develop the comprehensive FPC assembly business. We are in the leading position in terms of the accuracy of equipments, the investment volume and automation. The quality management system, inspection devices and labs are all available. Along with eco-value chain with customers, the value-added services are extended among upstream and downstream business, the one-stop solution is truly realized. Besides, all the products are complying with international environmental standard (RoHS). You will enjoy our flexible PCB manufacturing services without any hassle

.

Material selection, process tolerances, manufacturing logistics, and your flex supplier all play an important role in producing a cost-effective and reliable flex circuit design.

At O-Leading will assist you in design for manufacturing to minimize overall program costs. Listed are standard materials and capabilities.

Come speak with us should your design require tighter tolerances or special process treatments.

· Material Selection

|

Polyimide Thickness |

0.0005″ (12 um), 0.001″ (25 um), 0.002″(50 um), 0.003″ (75 um), 0.005″ (125 um) |

|

Copper (thickness) |

0.25 oz.(9 um), 0.33 oz.(12 um), 0.5 oz. (17 um), 1 oz.(35 um), 2 oz.(70 um) |

|

Copper Foils(rolled-annealed) |

Polyimide, Polyester, LPI (liquid photo imageable), PIC(photo imageable cover coat) |

|

Stiffeners |

FR-4, Polyimide, Metal, or customer supplied |

|

Thermo-bond Adhesives |

Acrylic, Phenolic Butyral, Modified Epoxy |

|

Surface Finishes |

Solder (hot air leveling or tin/lead plating), Electrolytic Soft Bondable Gold, Hard Gold, ENIG (electroless nickel immersion gold), Entek 106A, & Immersion Tin |

· Process Capabilities & Tolerances

|

Polyimide Thickness |

0.0005″ (12 um), 0.001″ (25 um), 0.002″(50 um), 0.003″ (75 um), 0.005″ (125 um) |

|

Copper (thickness) |

0.25 oz.(9 um), 0.33 oz.(12 um), 0.5 oz. (17 um), 1 oz.(35 um), 2 oz.(70 um) |

|

Copper Foils(rolled-annealed) |

Polyimide, Polyester, LPI (liquid photo imageable), PIC(photo imageable cover coat) |

|

Stiffeners |

FR-4, Polyimide, Metal, or customer supplied |

|

Thermo-bond Adhesives |

Acrylic, Phenolic Butyral, Modified Epoxy |

|

Surface Finishes |

Solder (hot air leveling or tin/lead plating), Electrolytic Soft Bondable Gold, Hard Gold, ENIG (electroless nickel immersion gold), Entek 106A, & Immersion Tin |