The new trends in antenna PCB materials

Laser drilling manufacturer china

As applications such as 5G and IOT will adopt higher frequencies, they will gradually increase from the past 3GHz to 6GHz or even 2 to 30GHz, which will bring new technological trends to antenna RF materials.

Jeff Grudzien, vice president of Rogers Advanced Board Materials Division, said at the 2016 Rogers Asia Advanced Interconnect Solutions Antenna Symposium, co-sponsored by Rogers and component distributor Shiqiang, said that the frequency is increasing. Plate loss has very high requirements.

How to achieve lower loss at high frequencies becomes a major challenge for 5G antenna panels. In addition, the number and complexity of 5G Massive MiMO antennas is much higher than that of 4G active antenna systems. Therefore, higher requirements are placed on reducing the size of the antenna. In addition, because of the need to integrate more things in a smaller size, 5G versus 4G also puts higher requirements on the thermal conductivity of materials.

What are the new trends in antenna PCB materials for 5G and IoT needs?

In addition to power boosting and device miniaturization, another challenge is how to perform the cooling function in a smaller space layout. “Our company has more research on plates with higher thermal conductivity values, because the selection of plates will be thinner due to the increase in frequency.

How to achieve our high thermal conductivity values on very thin materials is also a challenge. "Jeff Grudzien also said that as 5G communication adds more and more frequency bands to the antenna, there are already many antennas on the tower of the base station, and the antenna design becomes more and more complicated.

Because of the power boost, engineers want to put active circuits into the antenna system to form an active antenna system, which requires more components to be placed in a limited space. In this case, multi-layer PCBs began to replace the past cables to meet the complex antenna design requirements.

According to Jeff Grudzien, Rogers' unique thermoset resin meets the needs of the high frequency, multi-frequency, and complex antenna systems mentioned above. In the field of radio frequency, Rogers has a large market share. In 2014, Rogers acquired Yalong, an excellent manufacturer in the field of antennas, to expand its antenna product line. Before the acquisition of Yalong, Rogers' solution on the antenna was a thermosetting resin. Because this material was not previously familiar to most engineers in the country, it mainly uses Teflon materials (PTFE thermoplastic resin).

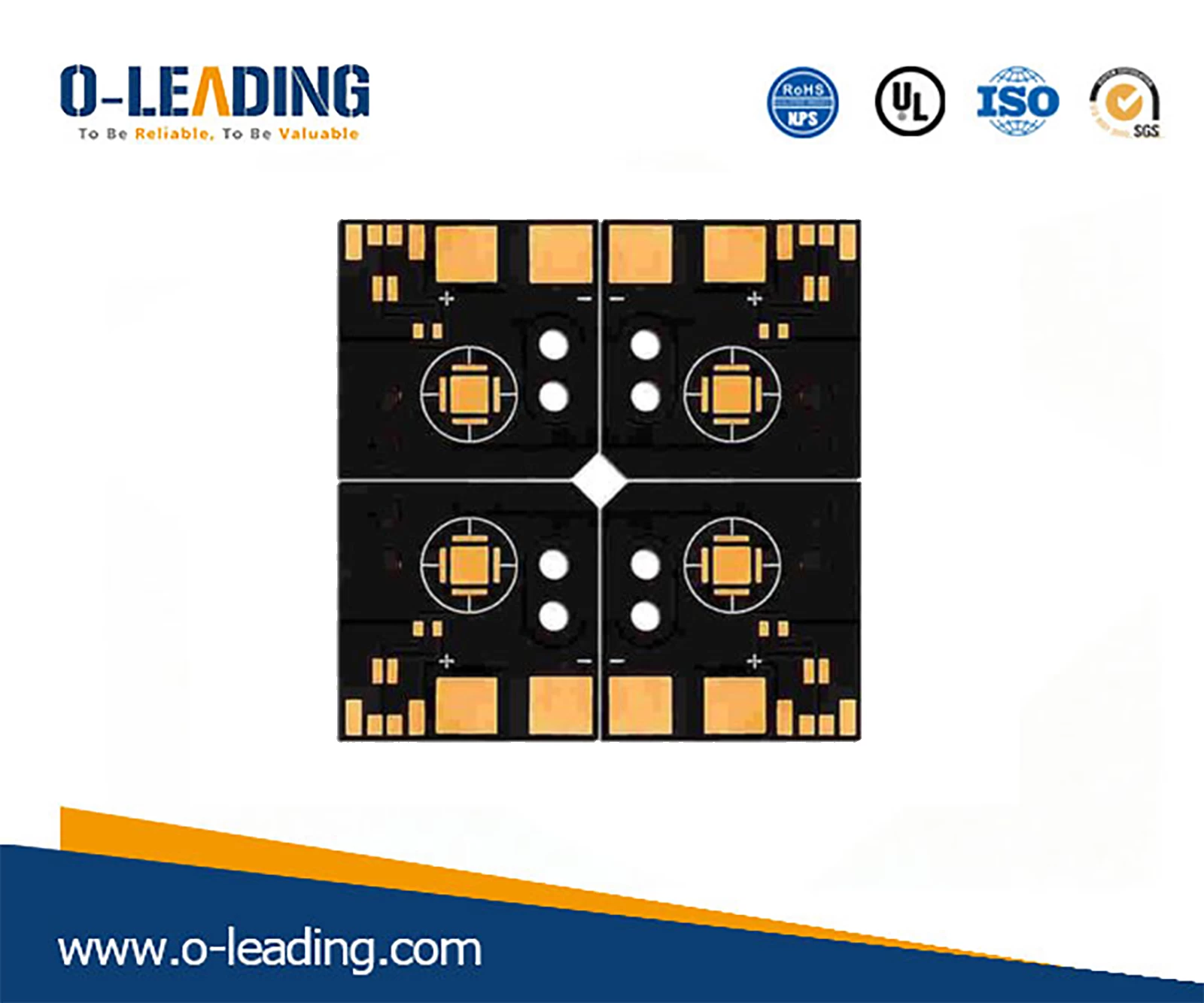

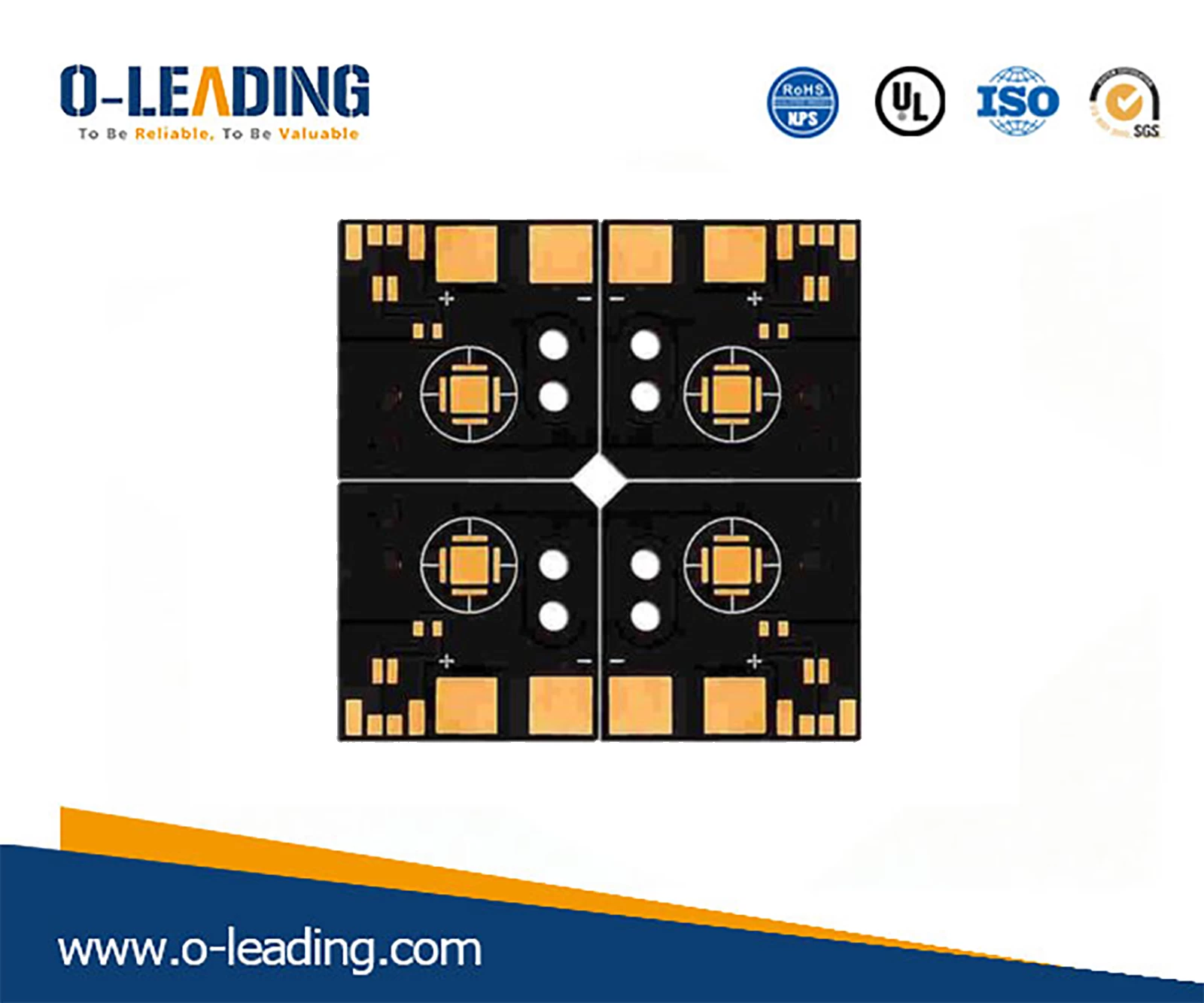

HEAVY COPPER BOARD manufacturer china

High temperature processing is usually an important part of high frequency circuit board processing and manufacturing. From the beginning of the formation of dielectric prepregs to copper clad laminates, as well as the final processing of circuit components, the production of printed circuit board (PCB) materials requires heating. Both thermoplastic and thermoset composites are commonly used in the dielectric layers of PCBs or as adhesives in the manufacture of copper clad laminates, each with its own characteristics and characteristics.

Thermoplastic materials are usually rigid or hardened, but as the temperature increases, the material will slowly soften as it approaches the melting point. Thermoplastic materials can be reinforced with fillers such as fiberglass or ceramic materials. The hardening process of a thermosetting material is the result of a thermochemical reaction.

For example, when two epoxy resins are mixed together, a chemical reaction occurs and the material hardens. Since they are initially soft or liquid, the thermoset material and the filler material can be enhanced by a simple process mixing.

But once hardened or cured, thermoset materials are generally harder than thermoplastic materials. The thermosetting material hardening process is an irreversible thermochemical reaction process that does not melt again like a thermoplastic material. Thermoplastic materials are stable at ambient temperatures, but the shelf life of thermoset materials prior to curing is limited.

Immersion Gold manufacturer china

Thermoplastic materials typically have less electrical losses than thermoset materials. In addition, as time passes and temperatures increase, the electrical properties of thermoplastic materials change less than thermoset materials. Thermoset materials oxidize over time.

The oxidation process can cause changes in the dielectric constant (DK) and loss factor (DF) of the PCB material and can cause potential changes in performance such as RF/microwave frequencies.

Through continuous research and improvement, Rogers scientists have also improved the performance of thermoplastic and thermoset materials in the PCB. By adding suitable filler materials, both electrical and mechanical properties are greatly improved.