PCB industry status and prospect analysis

In recent years, with the global electronics industry shifting to China, the focus of the PCB industry has also shifted to the mainland. Before 2000, 70% of global PCB production value was distributed in Europe, America (mainly North America) and Japan.

With the continuous transfer of production capacity, the Asian region has become the main global PCB supply base, with a total output value close to 90% of the global total, and mainland China has become the region with the highest PCB production capacity in the world.

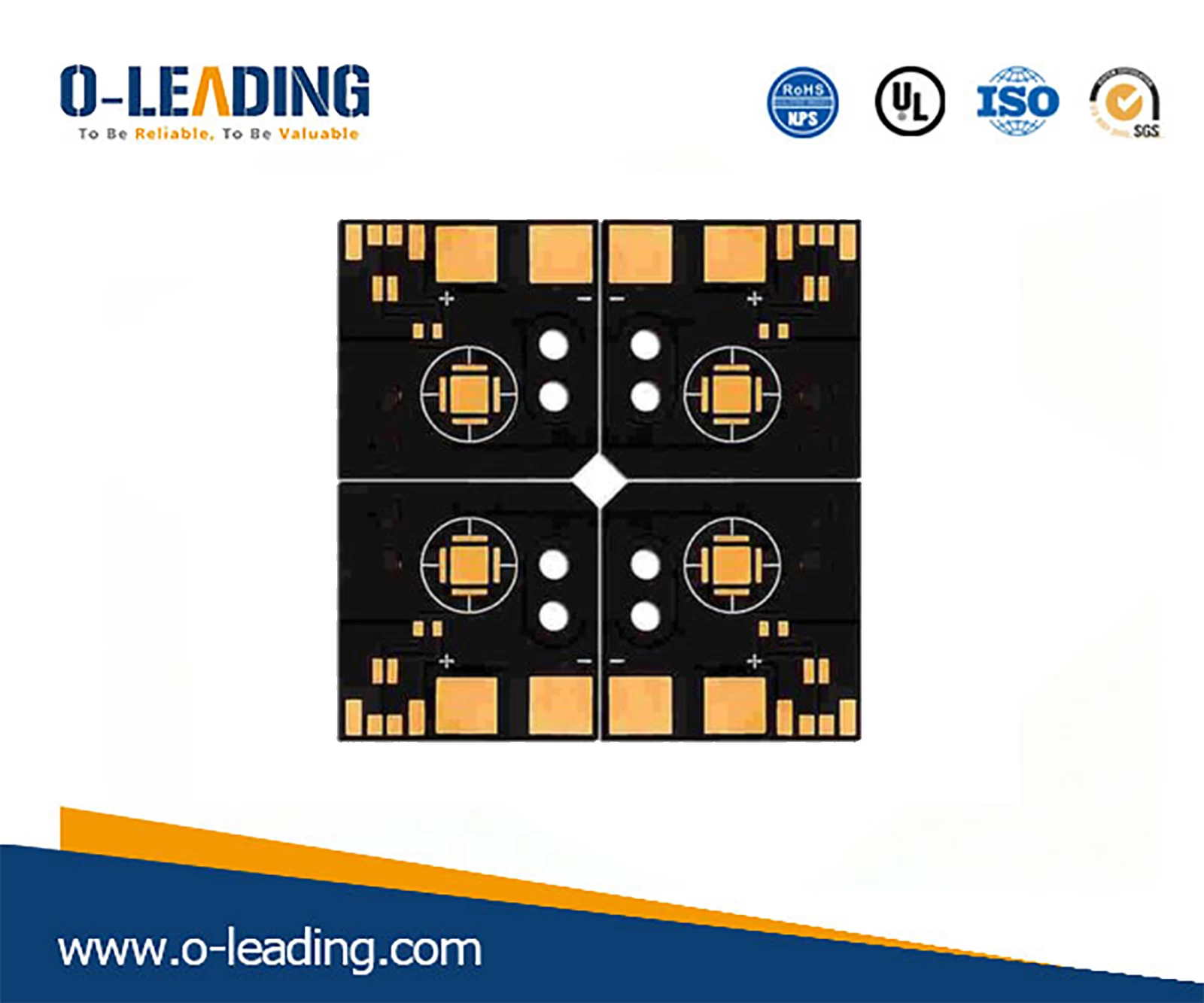

Prototype PCB Assembly company china

According to Prismark data, global PCB production value increased from 41.2 billion US dollars in 2009 to 58.8 billion US dollars in 2017, with an average annual compound growth rate of 4.55%. In 2017, China's PCB output value reached 29.732 billion US dollars, accounting for 50% of global GDP. %the above.

Second PCB industry development prospects

As the "mother of electronic products", PCB plays a leading role in the industrial chain, and its downstream application field is very broad. Traditionally, communications, computers, and consumer electronics are the main areas of domestic PCB applications. Now with the development of automotive electronics and the advancement of 5G construction, it is expected to drive PCB products to increase in volume in the next two years.

1 Automotive PCB is in the ascendant

Since 2012 to 2017, the global automotive electronics scale has increased from US$150 billion to US$230 billion in 2017, with an average annual compound growth rate of 9%. It is expected that the global automotive electronics market will reach US$250 billion in 2018.

In 2012, China's automotive electronics market was 44.5 billion US dollars, accounting for about 30% of the global automotive electronics market. In 2017, China's automotive electronics market grew to 82.6 billion US dollars, accounting for 36% of the global automotive electronics market, with an average annual compound growth rate. Up to 13%.

As the degree of electronic electronics continues to deepen, the proportion of automotive electronics in the overall manufacturing cost continues to increase. At present, the PCB area of the mid-range model is about 0.5~0.7 square meters, and the economical automobile PCB area is 0.3~0.4 square meters.

Assume that the average price of PCB is 1000 yuan / square meter, the average bicycle value is about 800 yuan, the luxury car PCB use area is about 2.5-3 square meters, the bicycle value is more than 2,500 yuan, with the car electronic degree deepening, the car PCB The demand area will gradually increase.

On September 13, the Ministry of Industry and Information Technology will further increase the support for the industrialization of key automotive and electronic products such as core chips and smart sensors, accelerate the formation of upstream and downstream interactive mechanisms, and promote the rapid and healthy development of China's automotive electronics industry.

2 5G construction arrow on the string, demand surge

The Information and Communication Industry Development Plan (2016-2020) issued by the Ministry of Industry and Information Technology clearly states that 5G commercial services will be launched in 2020.

According to the 5G promotion work plan proposed by the Ministry of Industry and Information Technology and the 5G commercial plan of the three major operators, China will launch the second phase of the 5G network test in 2017, and conduct a large-scale trial network in 2018, and on this basis, launch the 5G network in 2019. Construction, the official launch of commercial services in 2020.

Consigned PCB Assembly factory

Currently, the candidate band of 5G is a high frequency band above 6 GHz. The high frequency band means that the coverage radius is smaller. In an ultra-dense networking scenario, the small base station spacing will be reduced to 10-20 meters (a distance of at least 500 meters compared to the macro base station spacing). The number of small base stations will increase significantly. It is expected that the number of small base stations covered by 5G will need to reach tens of millions. The related infrastructure investment including PCB demand will be significantly improved.

In terms of price, the price of PCB for high-speed communication is about 3,000 yuan / square meter, which is much higher than the price of 1000 yuan / square meter below the ordinary single / double / multi-layer board.

Therefore, with the advent of the 5G era, the construction of small base stations continues to increase, the demand for high-speed communication PCBs increases, and the value of PCBs of communication base stations and the size of the PCB market will increase.

Three industry development favorable factors

1 Raw material prices rise, manufacturers raise prices

Since 2017, the prices of raw materials such as copper foil, epoxy resin and glass fiber have risen sharply, driving the price of copper clad laminates to soar, and the production cost of PCB has increased significantly.

With the rising tide of upstream raw materials, downstream PCB manufacturers have raised the price of PCBs to cover the cost and ensure the profit level. The PCB manufacturers represented by Morgan Electronics, Xingyuan Aerospace, and Zhongxin Laminate are in the 8th to 9th of 2017. PCB prices are adjusted to varying degrees, with the highest increase of 15%.

At the beginning of July this year, major PCB manufacturers such as Omway Electronics and Jianye Group once again issued price increase notices, and the overall price increase is expected to be 20%-30%.

Through the price increase strategy, PCB manufacturers successfully transferred the rising cost of upstream raw materials to the downstream, and the net profit was not affected too much. The performance of several PCB manufacturers showed signs of acceleration in the semi-annual report, ushered in the performance turning point, and the market performance was far stronger. In the broader market.

2 Environmental protection is strict, and production capacity is accelerated

With the country's emphasis on environmental protection issues, the environmental protection policy has been tightening in the past six months. For the high-pollution and high-emission industries such as PCB, the rectification efforts are relatively large. At the end of 17th, Kunshan issued a “Comprehensive Suspension Notice”, setting off a wave of restrictions on production.

Multilayer PCB manufacturer in China

Kunshan will implement a comprehensive shutdown of industrial enterprises affiliated to some river basins in Wusong River for nearly half a month due to water quality problems. It is reported that 62 PCB industry enterprises are involved. Since then, major PCB producing areas such as East China and South China have been environmentally rectified.

The tightening of environmental protection policies will trigger the accelerated withdrawal of PCB backward production capacity in mainland China. In the future, small PCB companies that fail to meet environmental protection requirements will be unable to carry out environmental protection requirements and gradually withdraw from the market due to their limited financial capacity.

For the large PCB enterprises that meet the environmental protection requirements, the listed companies such as Middle East Precision, Jingwang Electronics and Shennan Circuit have won environmental protection indicators, and the market concentration is expected to accelerate.

Along with the sharp increase in the prices of upstream raw materials and the tightening of environmental protection policies, many PCB small factories have been unable to withstand the pressures and shut down, and the industry concentration has accelerated.

In the process of reshuffling the PCB industry, leading enterprises have the inherent advantages in technology and capital, and can reduce costs and increase market share by expanding production capacity and upgrading technology.