The development trend of PCBA contracting materials

PCBA contract work is a very traditional business for all electronics factories, providing customers with a form of service from supply chain management, quality management, and production management. As a PCBA supplier, it is responsible for providing full-process services from circuit board production, raw material procurement, processing, testing, and assembly, saving customers costs in terms of time, cycle, and inventory. At present, this method has become the first choice for products produced by system integrators and product manufacturers. In recent years, new trends have also emerged in the field of PCBA contracting services.

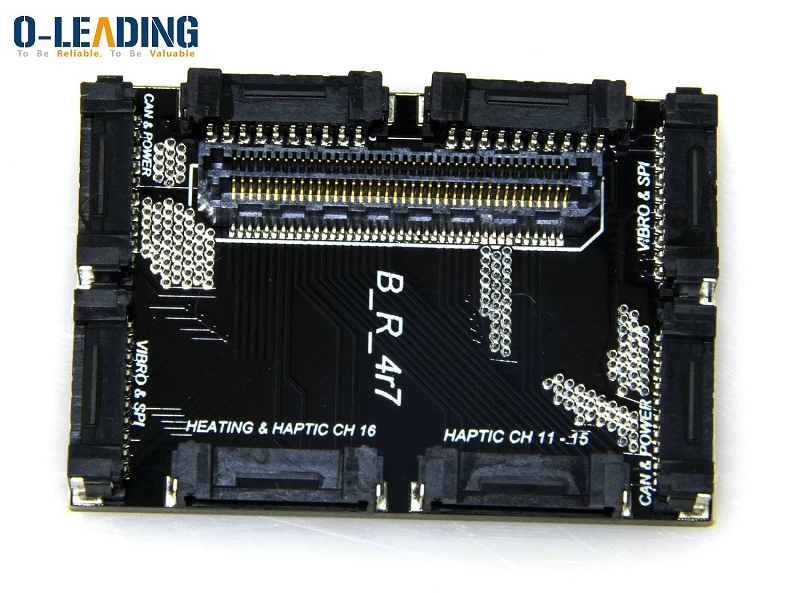

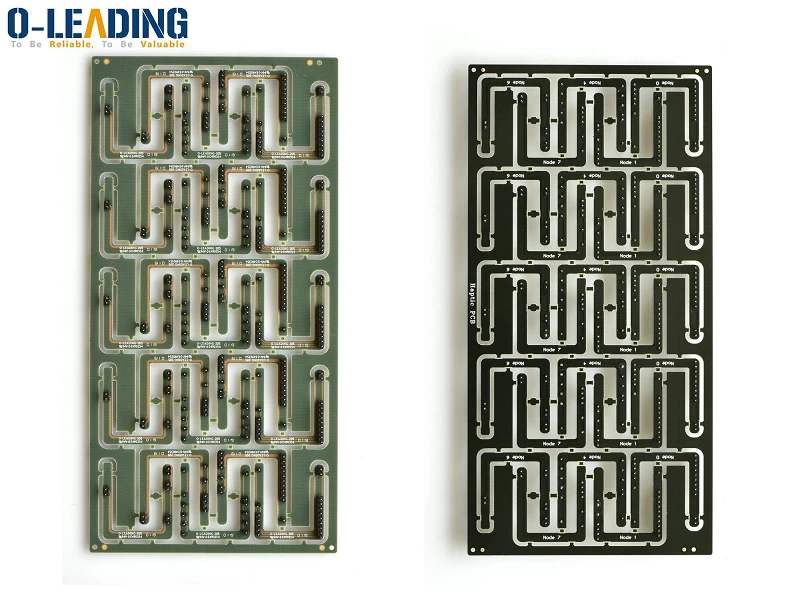

china pcb manufacturer,PCB Assembly in China, Graphics adapter board, your one stop provider of PCB&PCBA, SMT production line

1. The PCBA contracting work requires that the foundry have the ability to analyze and solve design problems

The upgrading of electronic products is getting faster and faster, and the life cycle of products is getting shorter and shorter. In many cases, it is no longer possible to give the product side too much laboratory verification process; the product will be put into the production process after the basic functions are available. At this time, the contractors and suppliers are faced with dealing with R&D and design issues in the production process. For example, some component parameters are not properly selected; some PCB circuit designs have defects. To cope with this situation, the foundry that does the contract work must make such preparations in terms of the production process and technical service capabilities.

Shenzhen PCBA one stop service SMD assembly PCB

Second, the control of PCBA contracting and packaging components gradually changes from model control to function control.

In the process of doing contract work and materials, sometimes it is inevitable that substitute materials will be encountered. Before, it was more about choosing alternative components, doing cost down, or making an emergency replacement. However, a more novel approach is to replace some functions with newer versions to achieve a leap in functionality and product quality. For example: the original switching power supply scheme of LM2596, because the product has relatively loose requirements for power supply ripple, it can be replaced with LM2576 with lower switching frequency. Choose alternatives based on the customer's product characteristics and usage environment rather than deadlock parameters. Realize the improvement of component control from model parameters to functional goals. create value for customers!

3. PCBA contracting materials from simple contracting materials to providing upgrade solutions.

The competition for products is becoming increasingly fierce, and upgrading is becoming faster and faster. More and more large customers also require the foundry to be able to provide some development work gradually while completing the work of contracting and packaging materials. Due to the long-term production of test products by the foundry, the electrical performance of the entire device is relatively comprehensive; if it is not a particularly large change, only the consideration of volume, power consumption, stability, user experience and cost, it can be passed through the foundry To achieve product upgrading. In this way, the foundry must also be prepared and accumulated in PCB production, power supply design, and stability design to be able to calmly respond to customer needs.

Custom oem one stop service pcba assembly pcb manufacturer

Times are constantly improving. If the foundry still wants to stay in the original PCBA contracting mode, it will inevitably face many challenges. Rather than doing so, it is better to jump out and face the new trend of the market and improve your ability to seek market opportunities.

O-leading PCB Assembly the entire PCB Assembly process including components purchase, PCBA mount and soldering, detection online, overall measurement is available to the customers, whose whole project cycles will be shortened effectively. Using your design, we orient individual parts on the PCBs and solder the assemblies together, returning finished PCBs to you.