Talking about the future trend of SMT placement machine

Mounter:Also known as "mounting machine" or "surface mount system",in the production line,it is placed behind the dispenser or screen printer,and the surface is mounted by moving the head.The component accurately places a device on the PCB pad.

With the modularization,modularization,dual-channel conveying,multi-cantilever,

multi-head structure,and the development of placement machine technology such as flight alignment and lightning mounting,in a placement machine,both speed and accuracy are considered.And the placement function has become a new direction,and a new high-performance placement machine that combines high-speed,high-precision,multi-functional and private intelligence will become the mainstream.

High efficiency:means improving production efficiency, placement machine processing output rate,reducing working time and increasing production capacity. Good,fast and save money is the eternal pursuit of manufacturing, especially in today's increasingly competitive world.

The main way to improve efficiency is automation,which is the technique or means of alleviating human labor,strengthening, extending and replacing human-related labor.From automatic control, automatic adjustment,automatic compensation,automatic identification,etc. to self-learning, self-organizing, self-maintenance, self-repair and other higher automation levels.

For automated CNC equipment such as placement machines, software programming efficiency is critical to improving placement machine efficiency. Develop more powerful software function systems, including various forms of PCB files, directly optimize the generation of patch program files, reduce manual programming time, develop placement machine fault diagnosis system and mass production integrated management system to realize intelligent operation An important part of the future development of high-efficiency placement machines.

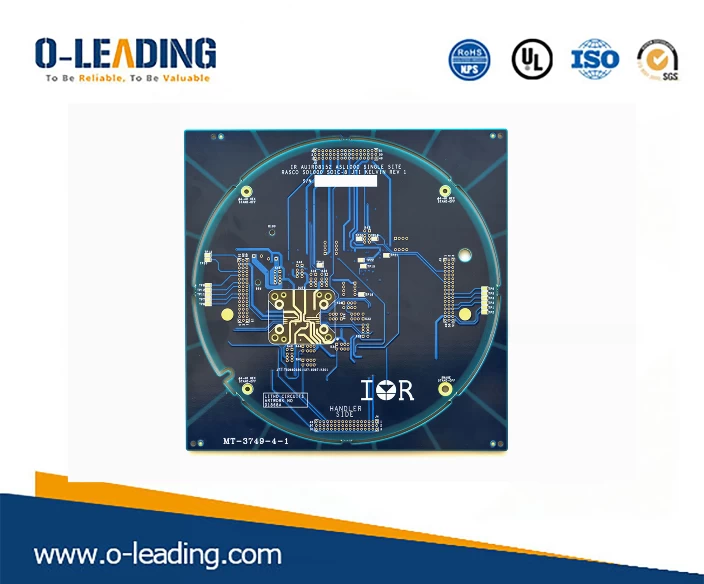

Power supply module manufacturer china

High integration:refers to two aspects,one is the integration of equipment technology,and the other is the integration of technology and management,the essence of which is the integration of knowledge.

(1) The integration of equipment technology requires multiple technologies to be crossed,grafted and integrated.For example,machine photoelectric integration;detection and sensing technology, information processing technology,automatic control technology,servo transmission technology,precision machinery technology and system overall technology comprehensive application;software and hardware technology coordination and integration.

(2) The integration of technology and management is to make full use of computer,automation and network technology to achieve organic integration of equipment application and management technology.The use of complete equipment,that is,automated production lines is particularly important.For example,when the factory introduces MES,SPC (Statistical Process Control) and traceability system are embedded in the SMT production line equipment,which can fully utilize the equipment performance and improve the mounting rate and quality.

Intelligent:The intelligence of manufacturing equipment is a promising direction for the development of manufacturing technology.In the past 20 years,the manufacturing system has been transformed from the original energy-driven type to the information-driven type,which requires the manufacturing system not only to be flexible,but also to show intelligence in order to deal with the processing of a large amount of complex information,the ever-changing market demand and fierceness.A complex environment of competition.The basis of the intelligent placement machine is computer intelligence technology.

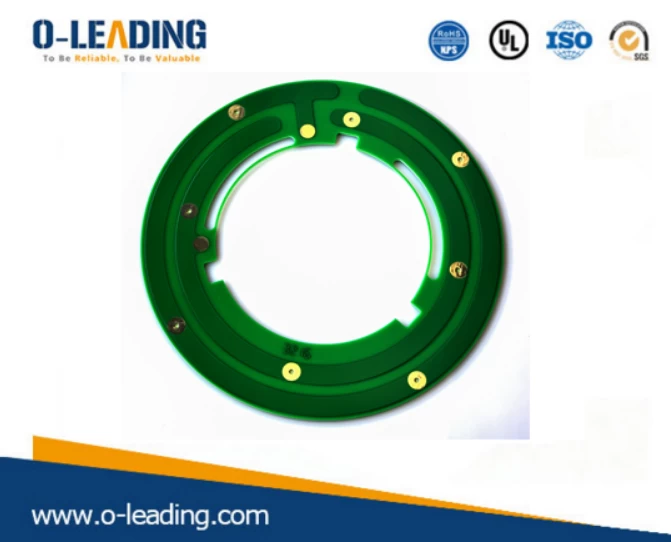

Depth control mechanical Microvia

Green: Green is an inevitable trend in the future development of electronics manufacturing. The development of human society is bound to move toward harmony between man and nature. SMT placement machines are certainly no exception.Future placement equipment must start from the conception,in the equipment phase,manufacturing phase,sales phase,use and maintenance phase,to the recycling phase,remanufacturing phase,must fully consider the impact on the environment, improve material recycling rate, reduce energy Consumption.

Diversification:The world today is a diverse and diverse world. Unbalanced development in different countries and regions,and uneven development in different regions of the same country, thus presenting diverse needs for electronic product levels and grades.At the same time,different application fields have different requirements for the reliability of electronic product application environments,and also make product manufacturing processes.And equipment to form a diverse demand.