PCBA power supply short circuit analysis method

Dealing with hardware,it will inevitably encounter some pins or network short circuit of PCBA.The most difficult problem is the short circuit of the power supply.Especially the board is more complicated,and there are many circuit modules,including BGA and other chips.Not easy to measure,but 3.3V short circuit.

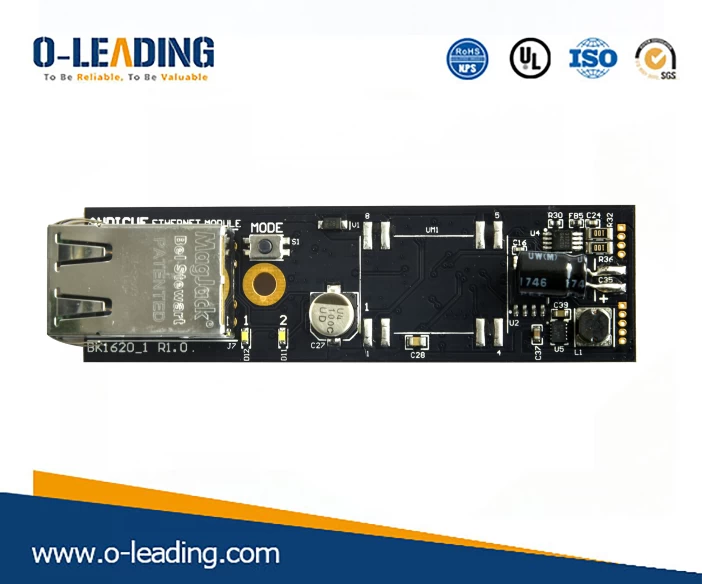

High quality PCB Assembly service

PCBA power supply is short-circuited.It may be that everyone will have a level one level check.In the case of visual inspection without finding problems such as even tin,first check if the corresponding power chip is broken (disconnect the rear stage circuit to see a short circuit),then look Look at which circuit modules of the short circuit use this power supply.At this time,the magnetic beads connected in series on the power supply or 0Ω play a role.Slowly eliminate and narrow the range until the short-circuited device is finally found.

The above method is naturally correct,but there is a problem that the efficiency is low,and it depends on luck.If you are lucky,you will find it.

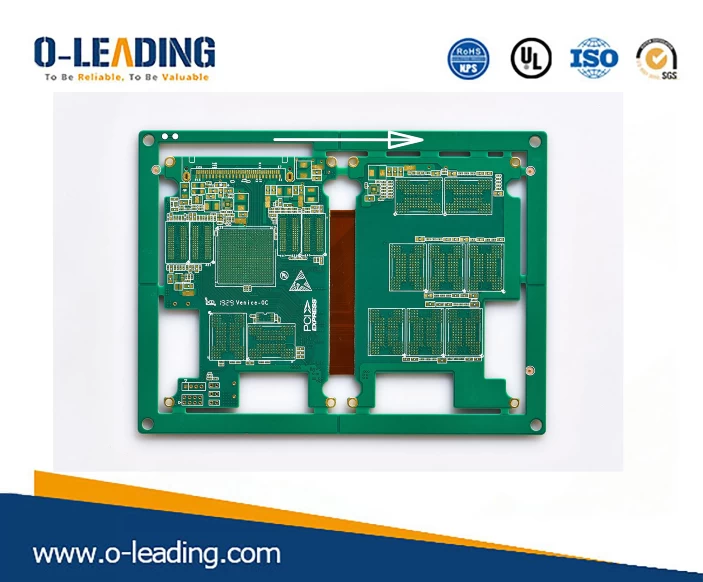

RoHs Compliant manufacturer china

Here is a trial and error analysis method: fever analysis

Introduction to the analysis method:

The fever analysis method is the name taken by the author himself.Generally,if the board is not short-circuited with tin,for example,if the chip is broken or the capacitor is broken, the GND resistor is generally not 0Ω,and it will have a few ohms or a few ohms more or less.With this feature, it can be quickly positioned.

Use DC stabilized power supply,adjust the power supply voltage to the voltage of the short-circuit power supply (3.3V short-circuit to 3.3V),set to current limit mode,limit current can be set to 500mA first,according to the actual situation.

Disconnect the power of the PCBA board,and put in the set power supply to see where the board is hot. Where is the hot one,which is usually short-circuited.

Check where the hot can be viewed with an infrared camera.If you don't have a thermal imaging camera,you can touch it directly,and feel it (pay attention not to burn).

Precautions:

The limiting current setting of the DC source needs to be determined according to the actual situation.If the current limiting setting is too small,the heating will not be obvious, and the problem cannot be found.If the setting is too large,the copper wire on the PCB may be burnt out,and the current can be changed from small to large.Slowly adjust until you find the problem.