PCB surface technology for PCB design

Hot air leveling (spray tin)

Hot air leveling, also known as hot air solder leveling (commonly known as spray tin), is a process in which molten tin (lead) solder is applied to the surface of the PCB and is heated (compressed) by heating compressed air to form a layer that is resistant to copper oxidation. It also provides a good solderability coating. When the hot air is leveled, the solder and copper form a copper-tin intermetallic compound at the junction. The PCB is sunk in the molten solder during hot air leveling; the air knife blows off the liquid solder before the solder solidifies; the air knife minimizes the meniscus of the solder on the copper surface and prevents solder bridging. Multilayer PCB manufacturer in china.

Organic Solderability Protector (OSP)

OSP is a process that meets the requirements of the RoHS Directive for printed circuit board (PCB) copper foil surface treatment. OSP is the abbreviation of Organic Solderability Preservatives. Chinese translation is organic solder mask, also known as copper protector, also known as Preflux in English. Simply put, OSP chemically grows an organic film on a clean bare copper surface.

This film has anti-oxidation, thermal shock resistance and moisture resistance to protect the copper surface from rust (oxidation or vulcanization) in the normal environment; however, in the subsequent high temperature of welding, the protective film must be very It is easily removed by the flux, so that the exposed clean copper surface can be immediately combined with the molten solder into a firm solder joint in a very short time.

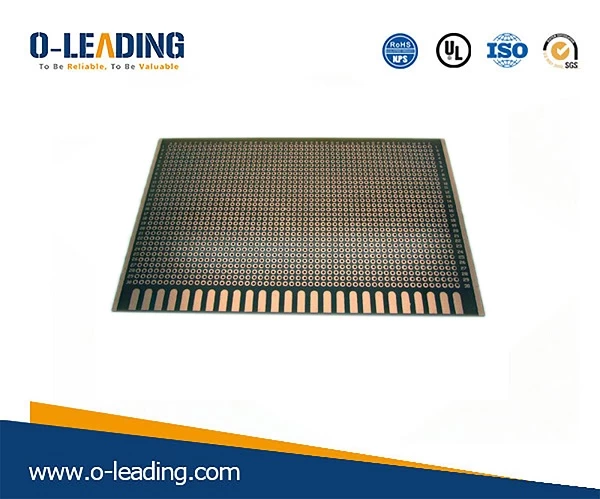

3D printer PCB supplier.

Full plate nickel plated gold

Nickel-plated gold is plated with a layer of nickel on the surface conductor of the PCB and then plated with a layer of gold. The nickel plating is mainly to prevent the diffusion between gold and copper. There are two types of electroplated nickel gold: gold-plated gold (pure gold, the gold surface does not look bright) and hard gold (the surface is smooth and hard, wear-resistant, contains other elements such as cobalt, and the gold surface looks brighter). Soft gold is mainly used for gold wire bonding in chip packaging; hard gold is mainly used for electrical interconnection in non-welded parts.

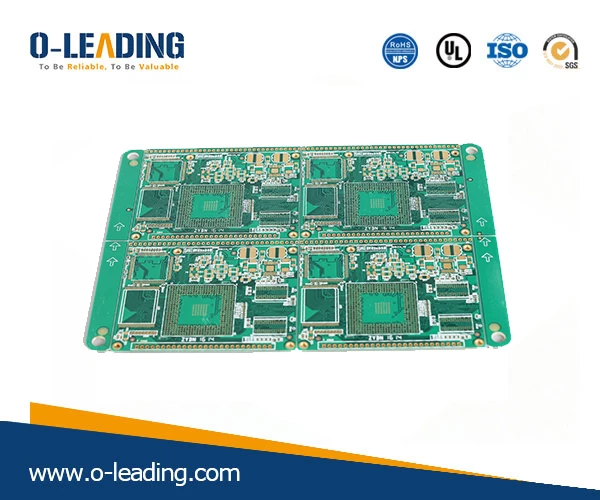

Printed circuit boards supplier.

Shen Jin

Shen Jin is a thick, electrically good nickel-gold alloy wrapped on the copper surface, which can protect the PCB for a long time. In addition, it also has environmental tolerance that other surface treatment processes do not have. In addition, immersion gold can also prevent the dissolution of copper, which will benefit lead-free assembly.

Shen Xi

Since all current solders are based on tin, the tin layer can be matched to any type of solder. The immersion tin process can form a flat copper-tin intermetallic compound. This property makes the immersion tin have the same good solderability as the hot air leveling without the hot air leveling headache. The slab can not be stored for too long. The assembly must be carried out according to the order of the tin.