PCB slicing analysis and factors affecting heating

Slice analysis technology:

It is one of the most common and important analysis methods in the PCB industry. Just like a doctor looking at an X-ray film, it can accurately determine the quality of the problem, analyze the cause of the problem, provide a basis for the solution and improve the evaluation process. Slicing analysis is mainly used to check the copper thickness, layer number, laminated structure, through hole diameter, copper thickness, hole wall roughness, etc. inside the PCB.

PCB slices can be divided into vertical slices and horizontal slices:

1. Vertical slice: It is cut in the direction perpendicular to the board surface to observe the cross-sectional condition. It is usually used to observe the quality of the hole after copper plating, the laminated structure and the condition of the internal bonding surface. Vertical slices are the most commonly used method in slice analysis.

2. Horizontal slicing: that is, grind down layer by layer along the direction of the board's stacking, used to observe the condition of each layer, usually used to assist the vertical slicing in the analysis and judgment of abnormal quality, such as inner short or inner opening abnormal, etc. .

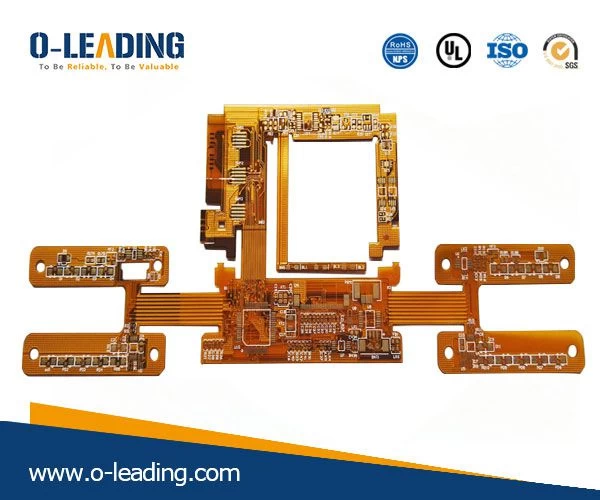

Rigid Flexible PCB supplier china

Slicing generally includes a series of methods and steps such as sampling, inlaying, slicing, polishing, etching, and observation to obtain a clean PCB cross-sectional structure. Then the microscopic details of the slices are analyzed through a metallurgical microscope. Only when the slices are correctly interpreted can the correct analysis be made to give effective solutions. Therefore, the quality of the slice is particularly important. Poor quality slices will bring serious misleading and misjudgment to the failure analysis. As the most important analysis equipment, the metallographic microscope has a magnification ranging from 50 to 1000 times, and the measurement accuracy deviation is within 1μm.

Factors affecting PCB heating

PCB heating is a headache, and the intensity of heat varies with the power consumption. The direct reason is that there are circuit power consumption devices, and different electronic devices have different degrees of power consumption.

Two phenomena of PCB heating

(1) Local temperature rise or large area temperature rise

(2) Short-term temperature rise or long-term temperature rise

When analyzing PCB thermal power consumption, generally from the following aspects:

1. Electrical power consumption

(1) Analysis of power consumption per unit area

(2) Analyze the distribution of PCB circuit board power consumption

2. The structure of PCB

(1) PCB size

(2) PCB material

3. PCB installation method

(1) Installation method (such as vertical installation and horizontal installation)

(2) Sealing condition and distance from the casing

4. Heat radiation

(1) Emissivity of PCB surface

(2) The temperature difference between the PCB and the adjacent surface and their absolute temperature

5. Heat conduction

(1) Install the radiator

(2) Conduction of other installation structural parts

6. Thermal convection

(1) Natural convection

(2) Forced cooling convection

The analysis of the above factors is an effective way to solve the PCB heating. These factors are interdependent and most of the factors should be analyzed according to the actual situation. Only for a specific actual situation can the temperature rise and power consumption be calculated or estimated more correctly. And other parameters.