PCB proofing The difference between lead spray tin and lead-free spray tin

The process requirements in board production are an important factor, and he directly determines the quality and positioning of a board. Such as spray tin, gold plating, immersion gold. Relatively speaking, Shen Jin is facing a high-end board. Due to its good quality, Shen Jin is relatively high in cost. Therefore, many customers choose the most common tin spray process. Many people know the tin-spraying process, but they don't know that tin is also divided into lead-tin and lead-free tin. So what is the difference between lead tin and lead-free tin? Take a look:

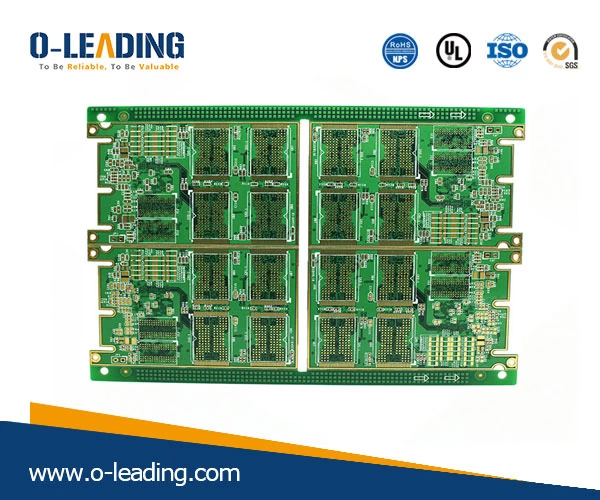

Step Slot manufacturer china.

1. From the surface of tin, lead tin is brighter, and lead-free tin (SAC) is dim.

2. Lead in lead is harmful to the human body, but not lead. The lead eutectic temperature is lower than that of lead-free. Specifically, it depends on the composition of the lead-free alloy. The eutectic like SNAGCU is 217 degrees, and the soldering temperature is eutectic temperature plus 30 to 50 degrees. It depends on the actual adjustment. The lead eutectic is 183 degrees. Lead in mechanical strength, brightness, etc. is better than lead-free.

CERAMIC WAFER manufacturer china.

3, lead and tin are brighter, lead-free tin (SAC) is more dim, lead-free infiltration is worse than lead.

4. The lead content of lead-free tin does not exceed 0.5, and the lead content reaches 37.

5, lead will improve the activity of the tin wire in the welding process, lead wire is relatively better than the lead-free tin wire, but lead is toxic, long-term use is not good for the human body, and lead-free tin will have a higher melting point than lead-tin. This makes the solder joints much stronger.