PCB design of crystal oscillator circuit

The crystal oscillators we often say are quartz crystal oscillators and quartz crystal resonators. They are all made by the piezoelectric effect of quartz crystals. Applying an electric field to the two electrodes of the quartz crystal causes mechanical deformation of the crystal. Conversely, if mechanical pressure is applied to both sides of the crystal, an electric field is generated on the crystal. Moreover, these two phenomena are reversible. With this characteristic, an alternating voltage is applied to both sides of the crystal, and the wafer generates mechanical vibration while generating an alternating electric field. This type of vibration and electric field is generally small, but at a certain frequency, the amplitude is significantly increased. This is the piezoelectric resonance, similar to the LC loop resonance we often see.

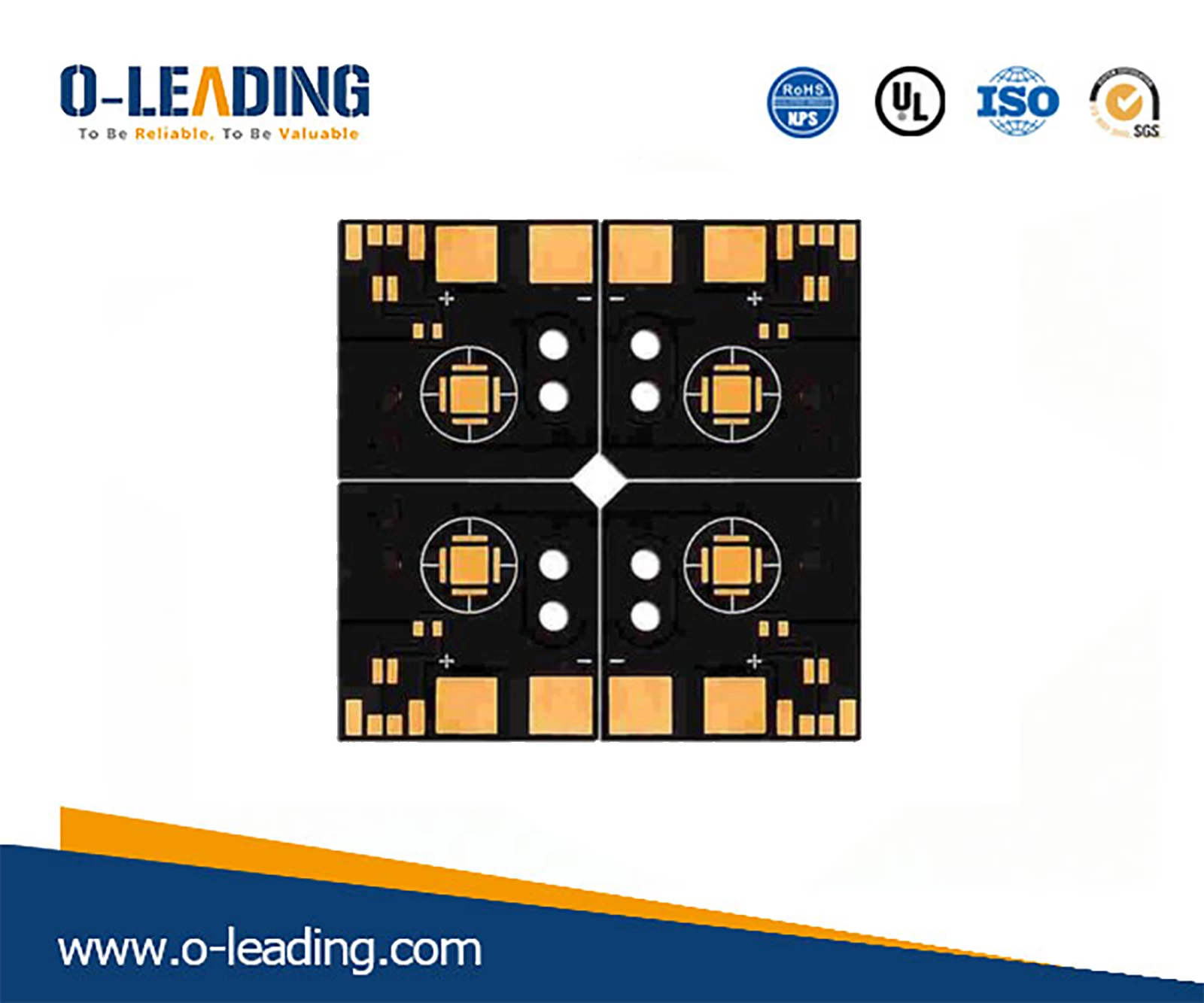

HEAVY COPPER BOARD manufacturer china.

Due to the importance of crystal oscillators in digital circuits, we need to be careful when using and designing:

1. There is a quartz crystal inside the crystal oscillator. When the external impact or drop occurs, the quartz crystal is broken and damaged, and the crystal oscillator is not vibrated. Therefore, when designing the circuit, it is necessary to consider the reliable installation of the crystal oscillator. The position is close to the CPU chip and is placed away from the board. side.

2. Pay attention to the welding temperature when welding by hand or machine. The crystal is sensitive to temperature, the temperature during soldering should not be too high, and the heating time should be as short as possible.

3. The coupling capacitor should be as close as possible to the power supply pin of the crystal oscillator. The position is placed in the order of the power supply inflow direction. The capacitance values are placed from large to small, and the capacitor with the smallest capacitance is closest to the power supply pin.

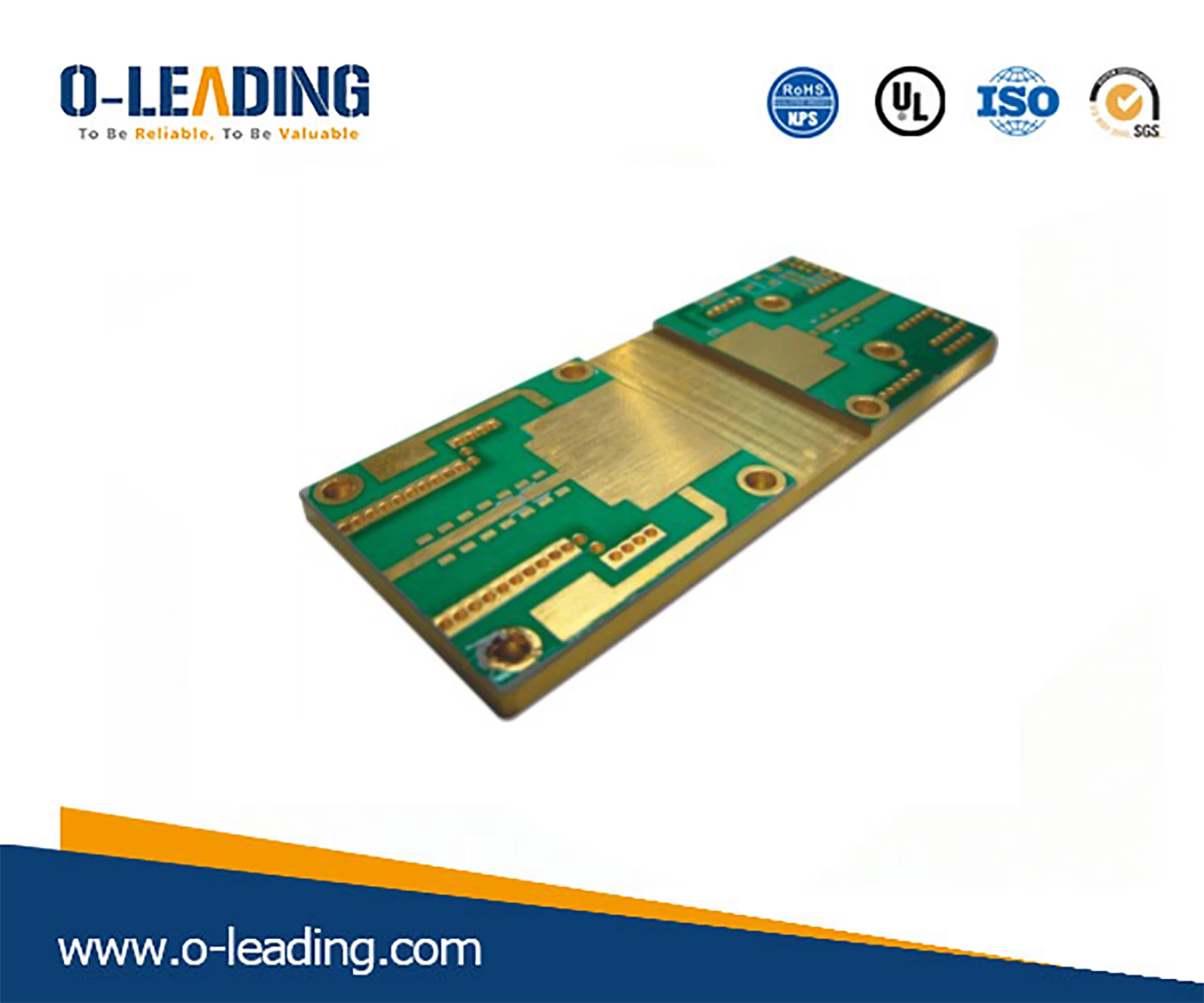

Engine Power Module manufacturer china.

4. The outer shell of the crystal oscillator must be grounded, which can radiate outward from the crystal oscillator, and can also shield the interference of the external signal on the crystal oscillator.

5. Do not route the crystal under the crystal to ensure complete grounding. Do not route the crystal within 300 mil range. This will prevent the crystal from interfering with the performance of other wiring, devices and layers.

6. The trace of the clock signal should be as short as possible, the line width should be larger, and the balance should be found in the length of the wiring and away from the heat source.

7, carry out the package processing

(Cylindrical crystal) Add a rectangular pad with the same shape as the crystal when the case is grounded. Let the crystal "lie flat" on this pad and open a hole near the two long sides of the pad. In the pad, it is better to replace the hole with a multi-layer pad, which is connected to the rectangular pad), and then use a copper wire or other bare wire to "clamp" the crystal. The two ends of the copper wire are soldered in the two holes or pads that you open. This can avoid the damage of the crystal by high temperature welding and ensure good grounding.

Of course, some people also add solder joints on the crystal to perform grounding treatment (must pay attention to the effect of temperature on the crystal during soldering)