PCB design preparations to avoid design overthrow

1. Appearance structure size, including positioning hole, air flow direction, input and output socket, need to match the customer system, also need to communicate with the customer on the assembly problem, limit height and so on. Industrial Power System PCB.

2. Safety certification, which kind of certification is made for the product, and where to make the basic insulation creepage distance should be enough, and where to strengthen the insulation to keep enough distance or slot.

3. Package design: There are no special periods, such as custom package preparation.

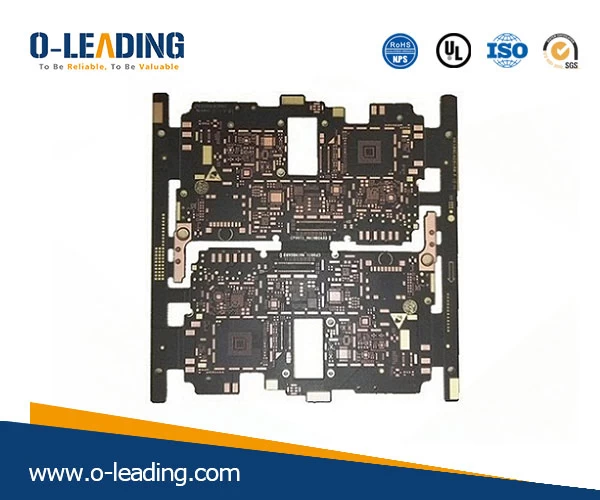

4. Process route selection: single-panel double-panel selection, or multi-layer board, based on the schematic and board size, cost and other comprehensive evaluation.

5. Other special requirements of the customer.

PCB for Medical Device.

The structural process is relatively more flexible, the safety regulations are still relatively fixed parts, what certification is done, what safety standards have been passed, and of course there are some safety regulations that are common to many standards, but there are also some special products such as medical treatments that are more demanding.

For the new entry engineers, friends are not dazzled;

Next, list some common products. The following are the specific layout requirements for IEC60065. For safety regulations, you need to keep in mind that specific products should be targeted:

Impedance PCB manufacturer china.

1. The distance required for input fuse pad parts is greater than 3.0MM, and the actual layout is 3.5MM (simply say that the fuse is 3.5mm creepage distance before the fuse, then according to the 3.0MM creepage distance)

2. The safety regulations of the rectifier bridge are 2.0MM, and the layout is 2.5MM.

3. After rectification, the safety regulations are generally not required, but the high and low voltages are kept at a distance according to the actual voltage. It is customary to use 400V high voltage to stay above 2.0MM.

4. The safety requirements between the primary and secondary are 6.4MM (interval), and the creepage distance is best according to 7.6MM. (Note that this is related to the actual input voltage, you need to check the specific calculation, the data is for reference only, subject to the actual occasion)

5. The primary and secondary use cold ground, hot and clear identification; L, N logo, input AC INPUT logo, fuse warning logo, etc. need to be clearly marked;

Again, the actual safety distance is related to the actual input voltage and the working environment. It is necessary to check the specific calculations. The data is provided for reference only, whichever is the actual situation.