PCB board component layout principles

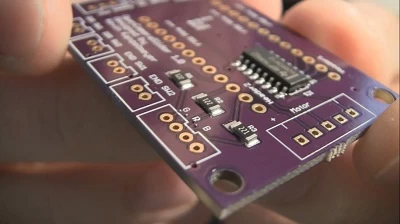

A :General principle: In the PCB board design, if the circuit system has both digital and analog circuits and high-current circuits, it must be laid out separately, so that the matching between the systems can be minimized in the same type of circuit, according to the signal flow direction. Function, block, partition to place components.

B: Input signal processing unit, the output signal driving component should be close to the edge of the board, so that the input and output signal lines are as short as possible to reduce the interference between the input and output.

C: Component placement direction: Components can only be arranged in both horizontal and vertical directions. Otherwise, the plug-in should not be used.

D: component spacing. For medium density boards, small components, such as small power resistors, capacitors, diodes, etc., the spacing between discrete components is related to the plug-in, soldering process. When wave soldering, the component spacing can be 50-100 MIL (1.27-2.54MM) can be larger by hand, such as 100MIL, integrated circuit chip, the component spacing is generally 100-150MIL.

China Mobile phone pcb board manufacturer

E: When the potential difference between components is large, the component spacing should be large enough to prevent discharge.

F: In the IC, the tantalum capacitor should be close to the power supply of the chip. Otherwise the filtering effect will be worse. In the digital circuit, in order to ensure the reliable operation of the digital circuit system, the power supply in each digital integrated circuit chip and The IC is placed between the ground to remove the tantalum capacitor. The tantalum capacitor is generally made of ceramic capacitor. The capacity of the capacitor is 0.01-0.1UF. The choice of tantalum capacitor capacity is generally selected according to the reciprocal of the system operating frequency F. In addition, at the entrance of the circuit power supply A 10UF capacitor is also required between the power and ground lines, and a 0.01UF ceramic capacitor.

G: The hour hand circuit component is as close as possible to the clock signal pin of the MCU chip to reduce the length of the connection of the clock circuit. It is better not to route the wire below.

To find out more about PCB,clich the link Printed Circuit Board Manufacturer