Method of soldering iron on PCB printed circuit board

When heating, the soldering iron tip should be able to heat the pad and component leads at the same time. The soldering iron is held by the pen holding method, and the small finger pad is placed on the printed circuit board. When soldering, not only the printed circuit board can be stabilized but also the stable soldering iron can be supported. Function, using this method to hold the soldering iron can adjust the contact area, angle and contact pressure of the soldering iron and the pad and lead.(oem pcb board Printed company)

After the copper foil lead reaches the solder melting temperature, first add a little solder to the lead wire of the soldering iron tip, and then slightly move the soldering iron tip to the end surface of the lead, fill the solder on the end surface of the lead again, and then draw the arc, Move the soldering iron and soldering one by one in the opposite direction of the lead bend, and finally remove the solder wire and the soldering iron from the printed circuit board to complete the soldering operation.

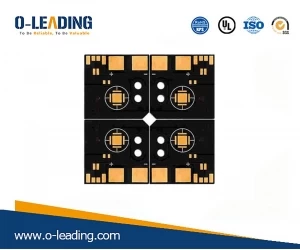

OEM Pcb prototype manufacturer china

For components that are not bent after the lead is inserted, a small amount of solder may be applied to the soldering iron tip to heat the lead and the pad. After the lead and the pad are heated, the solder is added from the opposite side of the lead and the soldering iron. After soldering, remove the solder and then remove the soldering iron.