- Contact Us

-

TEL: + 86-13428967267

FAX: + 86-4008892163-239121

+ 86-2028819702-239121

Email: sales@o-leading.com Contact Now

Contact Now

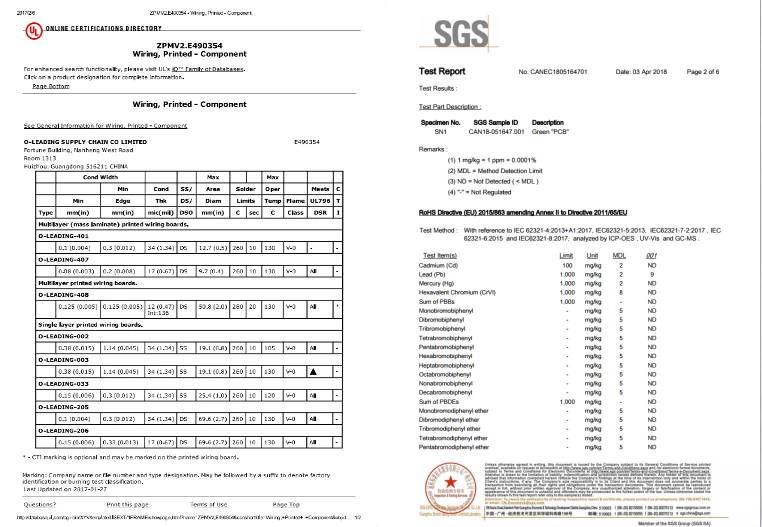

- Certifications

-

- Subscribe

-

Get email updates on new products

- New Products

-

Faster Networking Multi-Media Capability Powerful Processor Completely Upgraded Raspberry Pi 4 Model B 4GB RAM

AC DC Power Supply 110V 220V to 5V 700mA 3.5W Switching Switch Buck Converter, Regulated Step Down Voltage Regulator Module

China Top 10 Electronic Power Pcba Suppliers, Printed Circuit Board Pcba Power Assembly Manufacturer, Service PCBA Power Factory

Fast delivery PCB One Stop Service Circuit Board Manufacture PCB Assembly PCBA PCB receiver control board

SMT OEM PCB Manufacturer PCBA Service PCB Assembly Electronics Printer Control Sanitise Dispense Sensor Board

China Custom Multilayer PCB Board Service Half Plated Hold Wifi Module Small BGA Manufacturing Design

China Huizhou OEM Fast Lead Time Electronic PCB Board SMT Assembly PCBA Printed Circuit Board Manufacturer

China Electronic Circuit Board PCB Assembly Board customized SMT PCBA fabricatio Printed Circuit Board

Factory Price 0.2 6mm Thickness Electronic Hardware Plating Circuit Board,Double Side Pcb Hard Gold Board Manufacturer

led pcb board Printed circuit board, Printed circuit board in china, pcb manufacturer in china

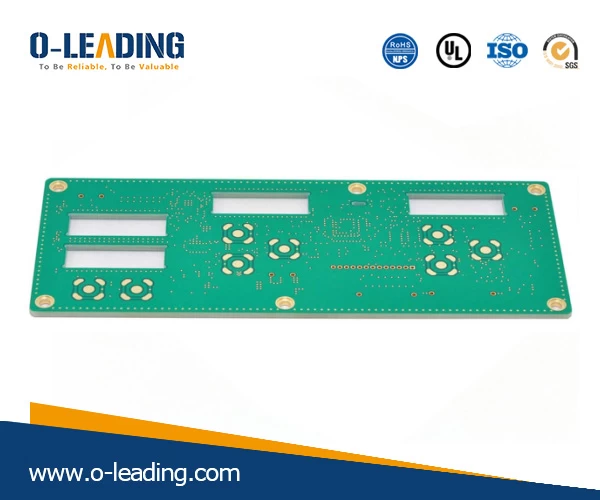

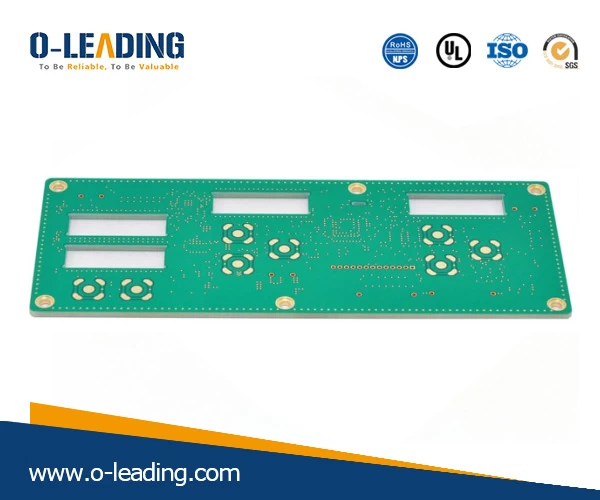

- PCB P/N:117_D53

- Layer Count:4L

- Material:FR-4 TG130

- Board thk:1.8mm

- copper thk:1/1/1/1oz

- Smallest hole size:0.3MM

- No. of holes (pcs):269

- line w/s:12/8mil

- Impedance control. Y / N (Tol %):N

- Surface Finishing:ENIG Au:0.05-0.10UM

- Solder Mask Silkscreen:Green

- Single board size:Dim X (mm):70;Dim Y (mm):176

- Panelisation:Dim X (mm):70;Dim Y (mm):176;No Of UPS:1

- Special: counter sink holes

- Routing/Punching:CNC

| Welcome to O-leading |

COPPER PLATE HOLES MINIMUM .025 AVG, .020 MIN.. HOLES MAY NOT BE PLUGGED

Pack with colorless transparent bubble film ,25 PCS/ bag, put desiccant in flank, put humidity indicator card on top side

| Product Description |

|

Place of Origin |

Guang dong, China (Mainland) |

Brand Name |

O-Leading |

|

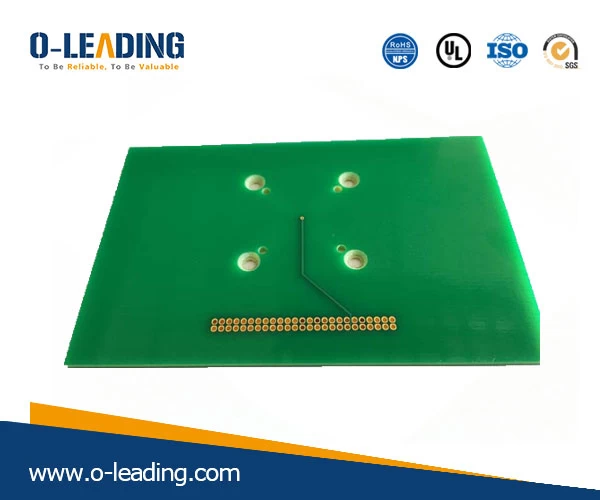

Base Material |

FR-4,,Aluminum |

Copper Thickness |

0.5oz-5oz |

|

Min. Hole Size |

0.2mm |

Min. Line Width |

0.2mm |

|

Surface Finishing |

immersion gold ,OSP,lead free HASL |

Board Thickness |

0.1-5mm |

|

applicable to |

led,mobile phone,air conditioners,washing machines |

character |

Industrial Control pcb |

|

certificates |

ISO9001,UL,RoHS,SGS |

Q/CTN |

10PCS-100PCS |

|

weight |

0.01kg -5kg |

MOQ |

10pcs |

| color | blue ,red ,green,black.yellow | Min. Line Spacing | 0.2mm |

| Model Number | power bank pcb assembly pcba manufacturer | price | $0.1-$10 |

| desigh type | client requirement | size | 0.01m3-10m3 |

Packaging & Delivery

|

Packaging Details: |

16 years professional OEM pcb board manufacturer |

|

Delivery Detail: |

7-12days |

Product Description

|

item |

2014 |

2015~2016 |

2017~2018 |

|||

|

Volume |

Sample |

Volume |

Sample |

Volume |

Sample |

|

|

Layer count |

32 |

42 |

38 |

44 |

42 |

48 |

|

Min Line/space (μm) |

50/50 |

40/45 |

40/45 |

40/40 |

35/40 |

35/35 |

|

Min drill hole |

0.15 |

0.10 |

0.15 |

0.10 |

0.15 |

0.10 |

|

Aspect ratio |

14:1 |

16:1 |

16:1 |

18:1 |

18:1 |

20:1 |

|

N+C+N |

4+C+4 |

5+C+5 |

5+C+5 |

6+C+6 |

5+C+5 |

6+C+6 |

|

Any layer interconnection |

5+2+5 |

6+2+6 |

5+2+5 |

6+2+6 |

5+2+5 |

6+2+6 |

|

Plate filling via |

YES |

-- |

YES |

-- |

YES |

-- |

|

Min. core thickness (exclude copper) (μm) |

50 |

40 |

40 |

30 |

40 |

30 |

|

Min. Laser Drill diameter (μm) |

75 |

65 |

65 |

50 |

50 |

40 |

|

Via on buried |

YES |

-- |

YES |

-- |

YES |

-- |

|

Material |

FR4, Megtron, Nelco, Rogers, Heavy Copper, etc. |

|||||

|

Embedded capacitor PCB

|

YES |

-- |

YES |

-- |

YES |

-- |

|

Surface Process |

Lead-free HASL, ENIG, OSP, Immersion silver, Immersion tin, |

|||||

| Our Team |

| Certifications |

| Packaging & Delivery |

| Packaging Details | 16 years professional OEM pcb board manufacturer |

| Delivery Detail | 7-12days |

| FAQ |