- Contact Us

-

TEL: + 86-13428967267

FAX: + 86-4008892163-239121

+ 86-2028819702-239121

Email: sales@o-leading.com Contact Now

Contact Now

- Certifications

-

- Subscribe

-

Get email updates on new products

- New Products

-

Faster Networking Multi-Media Capability Powerful Processor Completely Upgraded Raspberry Pi 4 Model B 4GB RAM

AC DC Power Supply 110V 220V to 5V 700mA 3.5W Switching Switch Buck Converter, Regulated Step Down Voltage Regulator Module

China Top 10 Electronic Power Pcba Suppliers, Printed Circuit Board Pcba Power Assembly Manufacturer, Service PCBA Power Factory

Fast delivery PCB One Stop Service Circuit Board Manufacture PCB Assembly PCBA PCB receiver control board

SMT OEM PCB Manufacturer PCBA Service PCB Assembly Electronics Printer Control Sanitise Dispense Sensor Board

China Custom Multilayer PCB Board Service Half Plated Hold Wifi Module Small BGA Manufacturing Design

China Huizhou OEM Fast Lead Time Electronic PCB Board SMT Assembly PCBA Printed Circuit Board Manufacturer

China Electronic Circuit Board PCB Assembly Board customized SMT PCBA fabricatio Printed Circuit Board

Factory Price 0.2 6mm Thickness Electronic Hardware Plating Circuit Board,Double Side Pcb Hard Gold Board Manufacturer

Ceramic Substrate Printed circuit board

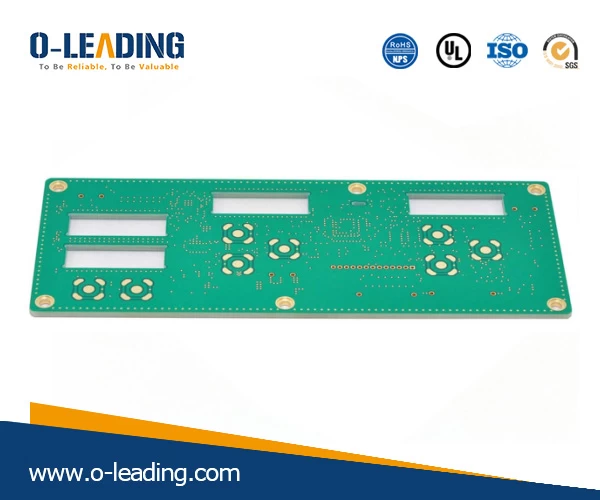

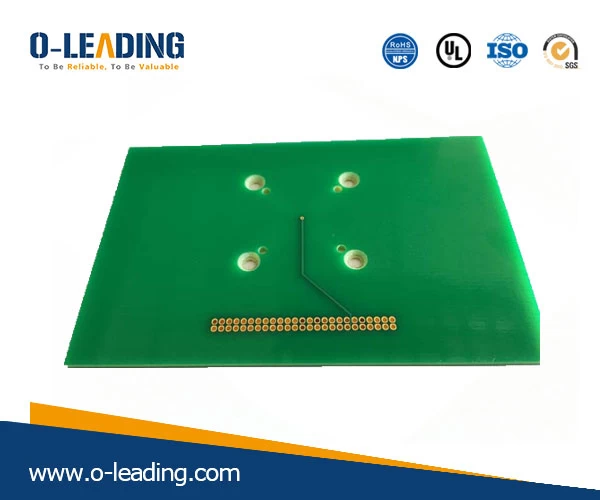

- PCB P/N:Q56253-H

- Layer Count: 2L

- Material:FR-4

- Board thk:1.60mm

- copper thk:1/1oz

- Smallest hole size:1.6MM

- No. of holes (pcs):668

- Impedance control. Y / N (Tol %):N

- Half milling technology

| Welcome to O-leading |

We are professional PCB manufacturer with more than ten years experiences . Products range-single, double side ,multi-layer PCB ,flexible PCB and MCPCB.We can provide fast prototype service – S/S in 24hrs , 4-8layers in 48-96 working hrs production time.

COPPER PLATE HOLES MINIMUM .025 AVG, .020 MIN.. HOLES MAY NOT BE PLUGGED

Pack with colorless transparent bubble film ,25 PCS/ bag, put desiccant in flank, put humidity indicator card on top side

PLEASE CLICK HERE FOR MORE INFORMATION: High Quality Ceramic PCB supplier

| Product Description |

| PCB P/N | Q56253-H |

| Layer count | 2L |

| Material | FR-4 |

| Board thk | 1.60mm |

| copper thk | 1/1oz |

| Smallest hole size | 1.6mm |

| No.of holes (pcs) | 668 |

| Impedance control. Y / N (Tol %) | N |

| Our Team |

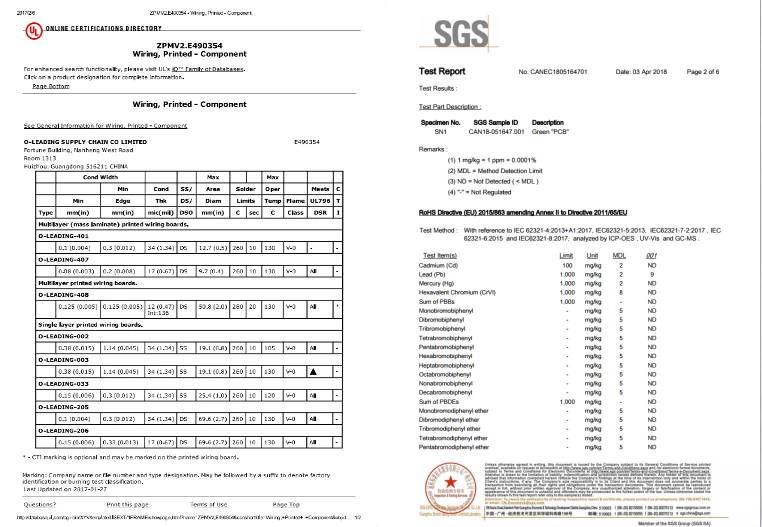

| Certifications |

| Packaging & Delivery |

| Packaging Details | 16 years professional OEM pcb board manufacturer |

| Delivery Detail | 7-12days |

| FAQ |

1. How do O-Leading ensure quality?

Our high quality standard is achieved with the following.

1.The process is strictly controlled under ISO 9001:2008 standards.

2.Extensive use of software in managing the production process

3.State-of-art testing equipments and tools. E.g. Flying Probe, X-ray Inspection, AOI (Automated Optical Inspector) and ICT (in-circuit testing).

4.Dedicated quality assurance team with failure case analysis process

5.Continuous staff training and education

2. How do O-Leading keep your price competitive?

Over the last decade, prices of many raw materials (e.g. copper, chemicals) had doubled, tripled or quadrupled; Chinese currency RMB had appreciated 31% over US dollar; And our labor cost also increased significantly. However, O-Leading have kept our pricing steady. This owns entirely to our innovations in reducing cost, avoiding wastes and improving efficiency. Our prices are very competitive in the industry at the same quality level.

We believe in a win-win partnership with our customers. Our partnership will be mutually beneficial if we can provide you an edge on cost and quality.

3. What kinds of boards can O-Leading process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

4. What data are needed for PCB production?

It is best to provide data in Gerber 274-X format. In addition, Cam350, CAD, Protel 99se, PADS, DXP and Eagle can also be processed.

5. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond → Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.