PCB processing of the process requirements

o-leading.com

o-leading.com

2017-06-12 11:27:21

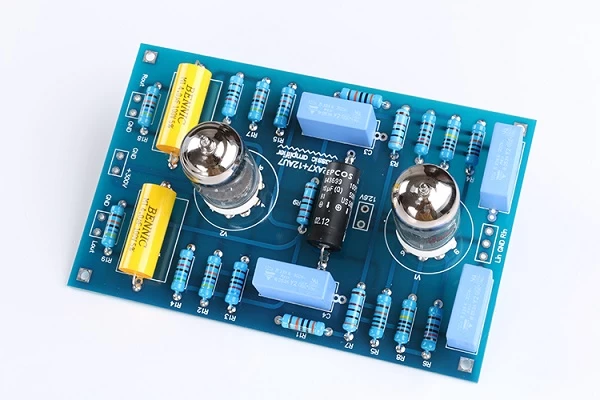

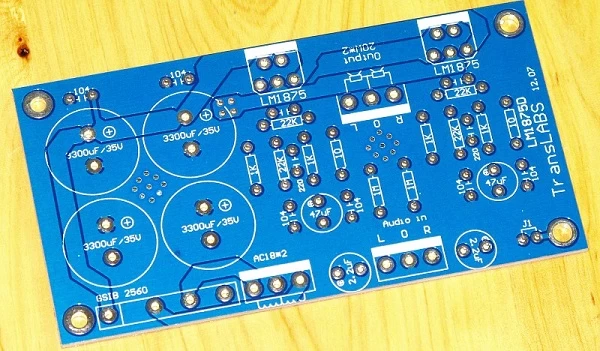

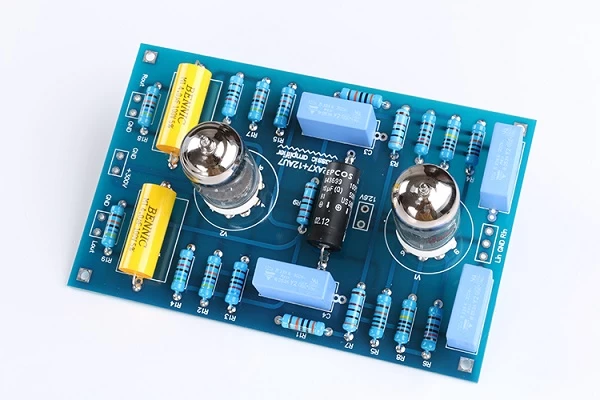

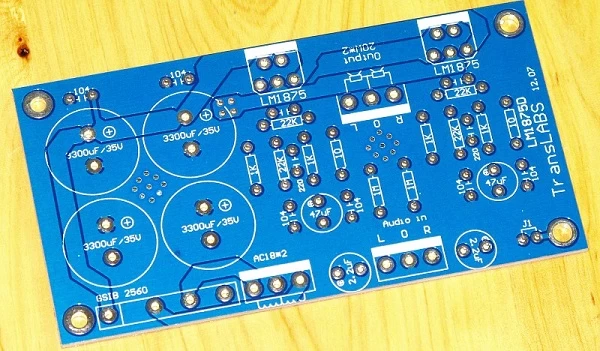

PCB processing has a different method, and PCB processing of raw materials is also tens of thousands, and there is no corresponding with the processing process, the same material with the same method of processing will have a difference in order. So for the professional Printed circuit board company, in the face of many processing methods PCB processing process requirements?

First, the number, PCB processing is completed, it should be immediately unified number. In order to prevent the mark in the process of processing, cleaning is lost, apply the marker to clearly write on both sides of the board writing a uniform number. This number should be retained permanently for future management.

Second, the correct placement, in order to make the surface of the device bumps as little as possible in the processing, transportation, and custody of the PCB process, we must pay attention to gently, to prevent the occurrence of bumps, and between the board Also need to isolate the code to avoid contact with each other, so that oem pcb board manufacturer china damage each other.

Third, the PCB processing of the finishing process, PCB processing and testing, but also the need for finishing the entire board of work, including the removal of the surface of the excess items such as excess pin and metal residues; after PCB processing Finished products for landscaping, such as should be as much as possible homeopathic concealment of the front line; for the back of the fly line is less or less, the best all take shortcuts; and solder joints and longer fly line to use the minimum glass glue will Its cover, fixed, so that it does not affect the external appearance. Because for the first-class PCB manufacturers, whether internal or external are equally important; so also to remove the excess logo, the color should be consistent and to keep the PCB board clean, such as stained dirt, use a brush or Cotton ball clean.

After each PCB processing is completed, have to undergo a tedious finishing work before packaging, and each consumer to get the finished products have gone through numerous procedures and can not have any errors. Each of the integrity of the pcb board manufacturer china are strict implementation of the above process, and also continue to excellence, only for their own more professional, only to trust its consumers to bring more affordable PCB processing products.

Second, the correct placement, in order to make the surface of the device bumps as little as possible in the processing, transportation, and custody of the PCB process, we must pay attention to gently, to prevent the occurrence of bumps, and between the board Also need to isolate the code to avoid contact with each other, so that oem pcb board manufacturer china damage each other.

Third, the PCB processing of the finishing process, PCB processing and testing, but also the need for finishing the entire board of work, including the removal of the surface of the excess items such as excess pin and metal residues; after PCB processing Finished products for landscaping, such as should be as much as possible homeopathic concealment of the front line; for the back of the fly line is less or less, the best all take shortcuts; and solder joints and longer fly line to use the minimum glass glue will Its cover, fixed, so that it does not affect the external appearance. Because for the first-class PCB manufacturers, whether internal or external are equally important; so also to remove the excess logo, the color should be consistent and to keep the PCB board clean, such as stained dirt, use a brush or Cotton ball clean.