Why are PCB boards mostly green

1. green solder mask ink is the oldest, and the cheapest and most popular.

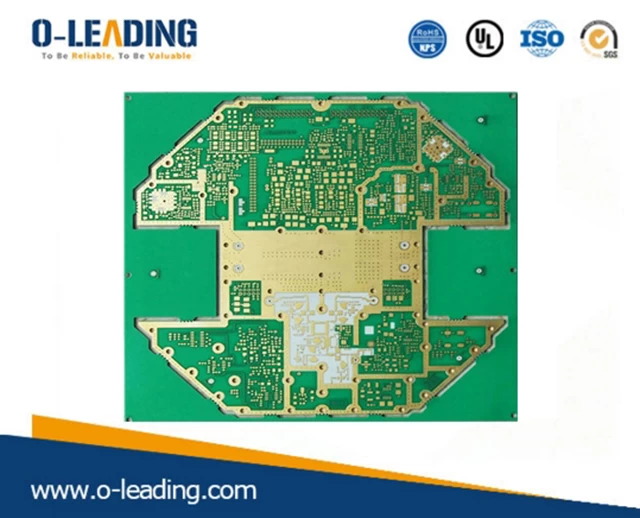

Laser drilling manufacturer china

2. In the manufacturing of PCB, there are several processes that need to pass through the yellow light room. The green has a better visual effect in the yellow light room, and when performing SMT soldering, it is necessary to go through the tin, the patch and finally The AOI calibration, these processes require optical positioning and calibration, and the instrument has a better recognition effect on the green-bottom PCB.

3, in general, the entire electronic board-level products have to go through the board and the patch process, there are several processes in the board making process to go through the yellow light room, the green in the yellow light room visual effect is better, but This is not the main one. In SMT soldering, it is necessary to go through the tin and the post and the final AOI check. These processes are all optically calibrated and calibrated. The green background color is better for the instrument.

4, common red, yellow, green, blue and black. Due to the problem of the process, many lines of inspection are still dependent on the workers' eyes (of course, most of them are now tested with flying probes). It’s a very tiring job to keep watching the board with strong light, and green is the least hurting eye. So most of them use green.

5, blue and black because of the cobalt and carbon, have a certain conductivity, so there is a risk of short circuit, green PCB is more environmentally friendly, will not release toxic gases when used in high temperature environment.

6, about from 2007, people began to pay attention to the color of the PCB board, mainly because many high-end panels of the first-tier manufacturers have adopted a green PCB color design, so people slowly think that the PCB color is green. Must be high-end.

Net Power Module manufacturer china

Of course, the ink used in PCB boards, in addition to the most common green, will be blue, yellow, white, red, and so on. Under normal circumstances, the use of white ink is to produce lighting, lighting, such products must use white PCB board, other colors are mostly product classification, for example, some companies use red to indicate the experimental board, and some use blue to Indicates the focus board, and some use black to indicate the board used for the inside of the computer.

In fact, the color of the solder mask ink has no effect on the finished board (except the appearance), but it will affect the difficulty of semi-finished products. For example, blue and black inks have a certain electrical conductivity due to the addition of cobalt and carbon, respectively, so there is a risk of short circuit. For another example, a black PCB board is the easiest to see the traces.

After that, more and more manufacturers began to use black PCB coating - it can be said that a strange reason has caused such a strange phenomenon. No one has ever said that the color of the PCB is black, which means that the quality of the motherboard is good. This is entirely due to the product misleading caused by the first-line brand using black to identify the product positioning.

Edge Plating manufacturer china

It is true that the black PCB is indeed able to demonstrate its own technical strength, because the black PCB is the easiest to see the trace, so no matter the design or after-sales will suffer unprecedented cost pressure, and the technical strength of the board manufacturers use black PCB The color tone is not because the black color can improve the performance of the motherboard. From the perspective of rational analysis, it is also known that the color alone cannot improve the performance of the board.

In short, the color of the solder mask ink has little to do with the performance of the PCB. From a rational point of view, it is impossible to improve the performance of the board by color alone.