What is the quality of PCB boards

o-leading

o-leading.com

2018-07-26 10:36:12

The most basic part of the processing of circuit boards, there is no need to talk about everything behind the PCB. All the processes behind the PCB without quality are all in vain, so in the electronic processing industry, every detail needs our attention and serious treatment.

Then, after the PCB circuit board is completed, the quality inspection of the circuit board is indispensable. So how to check the quality of the PCB?

1. Standard rules for size and thickness.

The thickness of the PCB board to the standard board is different. The customer can measure and check the PCB according to the thickness and specifications of the product.

Then, after the PCB circuit board is completed, the quality inspection of the circuit board is indispensable. So how to check the quality of the PCB?

1. Standard rules for size and thickness.

The thickness of the PCB board to the standard board is different. The customer can measure and check the PCB according to the thickness and specifications of the product.

2. The appearance of the weld.

Due to the large number of PCB circuit board parts, if the welding is not good, the circuit board that the parts are easy to fall off seriously affects the welding quality of the circuit board, and the appearance is good. It is very important to carefully identify the interface.

Due to the large number of PCB circuit board parts, if the welding is not good, the circuit board that the parts are easy to fall off seriously affects the welding quality of the circuit board, and the appearance is good. It is very important to carefully identify the interface.

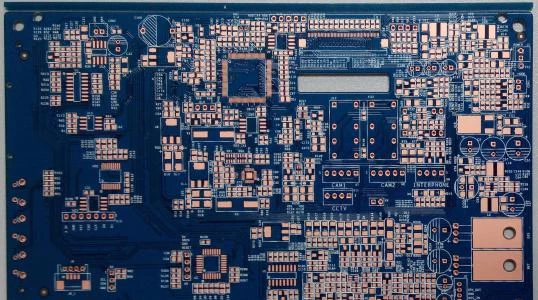

3, light and color.

The external PCB circuit board has ink coverage, and the circuit board can play the role of insulation. If the color of the board is not bright, there is less ink, and the insulation board itself is not good.

The external PCB circuit board has ink coverage, and the circuit board can play the role of insulation. If the color of the board is not bright, there is less ink, and the insulation board itself is not good.

In fact, the performance of the PCB board is determined by the materials used, the wiring design and several layers of boards. However, in the process of washing the PCB, black is the most likely to cause chromatic aberration. If the raw materials and manufacturing processes used in the PCB factory are slightly deviated, the PCB defect rate will increase due to chromatic aberration. This directly leads to an increase in production costs.

Since the black PCB's circuit traces are difficult to identify, it will increase the difficulty of repair and debugging during the R&D and after-sales phases. Generally, if there is no strong RD (R&D) designer and a strong maintenance team, the black PCB will not be easily used. of. It can be said that the use of black PCB is a brand's confidence in the RD design and the post-maintenance team, but also the performance of the strength.