The role of PCB in the medical field

2020-10-15 19:20:31

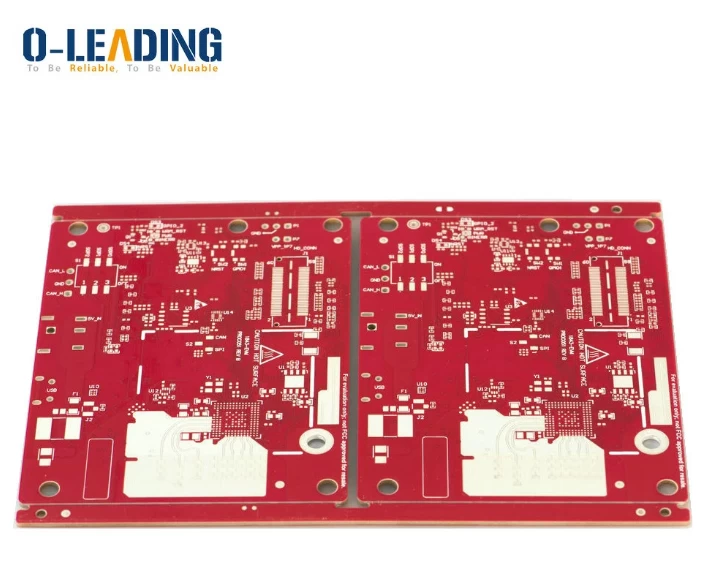

Special care must be taken to ensure the reliability of medical PCBs when producing medical PCBs, because proper functions are essential to the health of patients. In many cases, PCBs must also meet strict hygiene standards, especially those used for implants. The boards used for implants and many other applications (such as emergency room monitors) must also be relatively small. Therefore, many medical PCBs are high-density interconnects or HDIs.

PCB is used in medical equipment, such as:

Medical imaging systems: CT, CAT and ultrasound scanners often use PCBs, and computers that compile and analyze these images also use PCBs.

Monitors: Heart rate, blood pressure, blood glucose monitors and more devices that rely on electronic components to get accurate readings.

Infusion pumps: Infusion pumps (such as insulin and patient-controlled analgesic pumps) deliver precise amounts of fluid to the patient. PCB helps ensure that these products operate reliably and accurately.

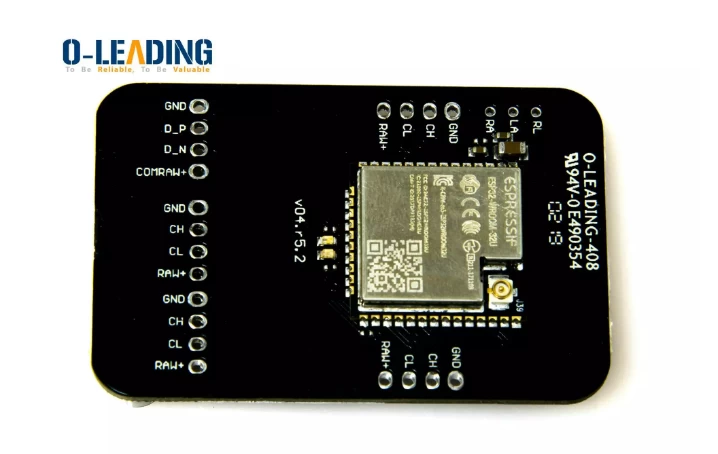

Internal equipment: Pacemakers and other equipment used internally require a small PCB to function.

The medical field continues to develop more electronic uses. As technology advances and smaller, denser, and more reliable boards become possible, PCBs will play an increasingly important role in healthcare.

O-LEADING provided stable and reliable PCB manufacturing solution to over 1,000 customers from all over the world.Our products range from 1 to 32 layers, We are your expert of PCB fabrication and providing advanced PCB technology products.

You can contact sales@o-leading.com

We forward to serving you.

You can contact sales@o-leading.com

We forward to serving you.