SMT electronic component polarity recognition method

With the transformation of mobile phones to the smart era, SMT electronic components have also changed to integration and miniaturization. The layout of PCBA components is becoming more and more compact, Various components can no longer identify component polarity on the PCB board, and a large number of new components are used, Make the process of SMT component polarity recognition, there are troubles and problems, here is a summary of component polarity recognition methods:

Purpose: In order to avoid adverse phenomena such as component polarity reversal in the production process, improve quality personnel's understanding of the direction of polar components, and ensure the correctness of first piece production and component polarity confirmation.

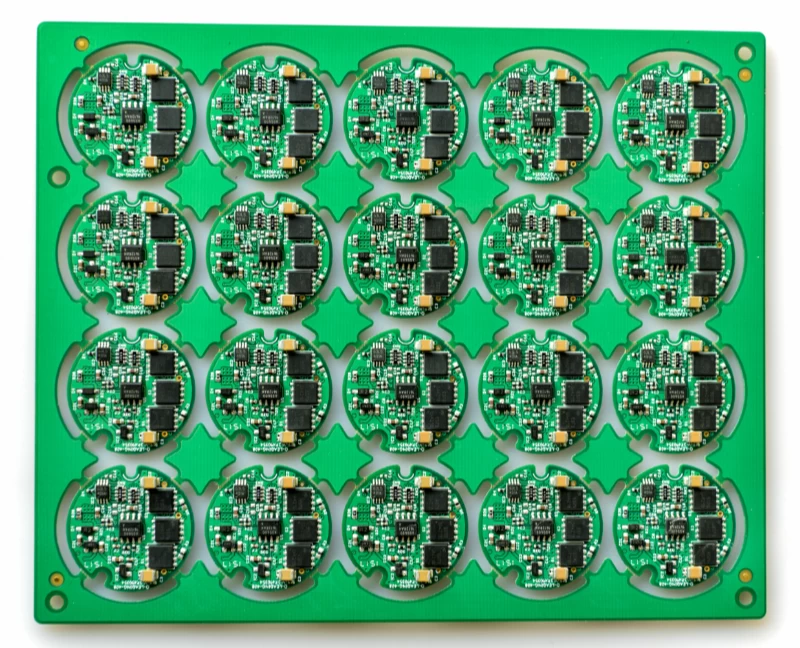

Industrial controller SMT assembly factory pcba

Component polarity refers to the direction of the component or the position of the first pin of the component. Polarity means that the component needs to be mounted in a certain direction when it is mounted on the PCB. Ensure that the positive and negative poles of the component or the first pin of the component are connected to the PCB. The actual circuit of the board matches. If the direction is not correct when mounting, it will cause the circuit to be blocked, the component body will be short-circuited and burned, and the circuit will not work normally.

Types of polar components:

At present, there are many components with polarity, and the ones that can be touched are: shaped capacitors (symbol: C), diodes (symbol: D or DS), transistors (symbol: Q), IC integrated circuits (symbol: IC), field Effect tube, transformer, coil (symbol: T), crystal oscillator (X), row socket, shielding frame, etc.

Marking of polar components

1. Generally, there will be a mark on the component with polarity indicating the position of the positive and negative poles or the first pin of the component. Generally, for two-pin components, the marks on the component are mostly positive and negative marks; for multi-pin components, the mark on the component is the position of the first pin of the component.

2. If there are polar components that are mounted on the PCB board with incorrect polarity, we call it poor reverse. When the components are reversed, even if they are accurately mounted on the PCB board pad and soldered well, it cannot be satisfied. Effective electrical connection. It will also cause PCBA burnout during testing and poor function.

Component polarity recognition should be done from three aspects

1. Component body polarity recognition: the position of the positive and negative poles or the first pin of the component marked on the electronic component body.

2. Recognition of the polarity of the components on the PCB board or in the circuit: the position of the positive and negative poles of the electronic components on the PCB board or the first pin in the circuit is marked.

3. The electronic components are mounted on the PCB, and the polarity of the component body corresponds to the polarity required by the circuit.

The PCBA produced by SMT is becoming more and more integrated, the components are becoming more and more precise and tiny, and the layout of the components is becoming more and more precise. This makes products such as mobile phone motherboards have no components on the PCB board. It is impossible to intuitively judge the polarity of the component.

For this kind of product, the quality uses the electronic version of the component tag map provided by the development to make a material release map, which clearly identifies the location tag, specification and polarity of each component, so that the quality personnel can confirm the first piece and sample inspection Refer to the use at the time to ensure the correctness of the component polarity judgment.