PCB industry competition analysis based on the barriers

(1) Funding barriers

The PCB industry has high requirements for capital. In the cost structure of the entire product, fixed costs can account for more than 40%. An ordinary PCB production line needs more than 20 million yuan, a multi-layer board needs to invest 50 million yuan, HDI needs to invest more than 200 million yuan, and a new production line with an annual production capacity of more than one million square meters needs to invest at least several hundred million yuan.

Therefore, the pre-investment of the printed circuit board industry is relatively large, and manufacturers must have strong financial strength. In order to maintain the continued competitiveness of the products, manufacturers must constantly upgrade the production equipment and processes, and maintain high R & D investment to keep up with the pace of industry changes. The distinguishing feature in PCB production is customized production. Large PCB manufacturers develop different production plans for different customers or different product requirements of the same customer, and select different production equipments, which further highlights the fundamental role of capital strength in enterprise development.

(2) Technical barriers

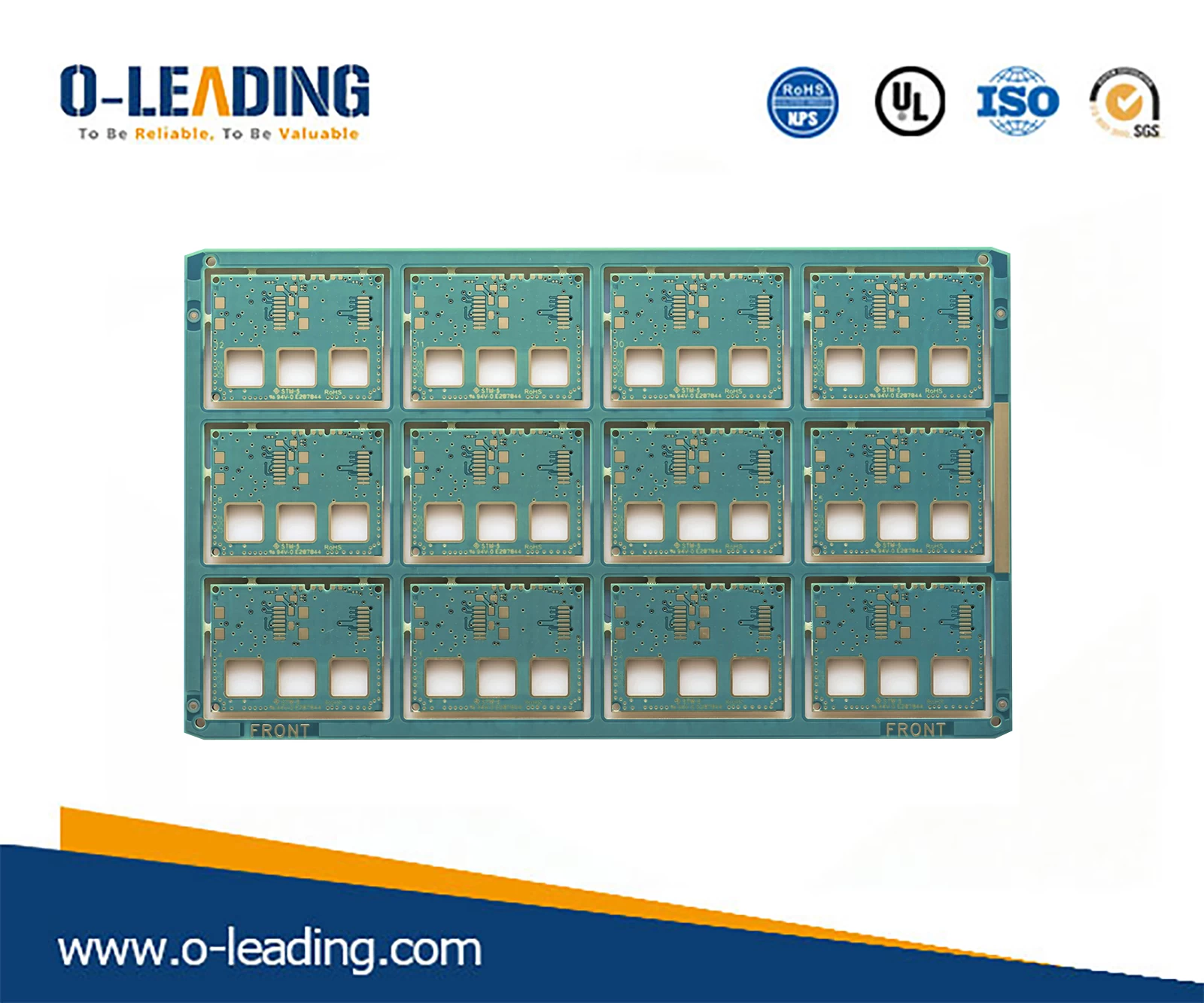

Printed circuit boards are a complex segment of the market. Although different printed circuit boards have some common basic processes, more importantly, according to the thickness and material of the substrate, the required line width and line spacing, accuracy, PCB structure, production scale, assembly process and customer specified requirements, combined with the characteristics of the production enterprise and the experience of various types of customers, determine different production processes and equipment, and carry out customized production and service.

On the other hand, the types of PCB products are rich and complicated. Although rigid boards, flexible boards, HDI, etc. have common points in the process, in the specific production, each type of product has its own independent production system, which is often some The reason why small and medium-sized manufacturers concentrate on producing a certain type of PCB products cannot meet the level of large-scale manufacturers that can satisfy the "one-stop procurement" of downstream customers.

(3) Customer recognition barriers

Printed circuit boards are the basic components of electronic products, and their quality is directly related to the function and life of electronic products. Therefore, downstream customers of printed circuit boards, especially high-quality large customers, have higher requirements on the quality of printed circuit boards. The industry generally adopts the “Qualified Supplier Certification System”, which requires PCB manufacturers to have a sound operation network, an efficient information management system, rich industry experience and a good brand reputation.

Especially for some international leading brand customers, when selecting qualified suppliers, they not only pay attention to product performance, quality and stability, but also audit procedures, “6S” (finishing, rectification, cleaning, cleaning, literacy, safety) management, factory operation specifications. Many soft assessment indicators such as production procedures, environmental protection, employee benefits and social responsibility. The certification process is strictly complicated and takes a long time.

(4) Environmental protection barriers

Electroplating, etching, development, and film removal processes in the PCB production process will generate a large amount of industrial waste water, so the environmental protection requirements for electronic product production are becoming increasingly strict in countries around the world.

Following the EU's Directive on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS), the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) requirements, the Chinese government has also issued Electronic Information. Measures for the Prevention and Control of Product Pollution Prevention (China RoHS), and announced that it will uphold the scientific development concept and take “energy saving, emission reduction, consumption reduction and efficiency improvement” as the primary goal of development.