PCB hot melt adhesive

Compared with silica gel, hot melt adhesive has the advantages of fast curing, and the flame retardance of hot melt adhesive is also good. Generally, it has FDA and UL94 certification, up to 94V0 level. It is a non-structural adhesive, which can be disassembled, reworkable, and cool down It can be cured, quickly reach the initial adhesion strength, and can be used for fixing electronic components and fixing wiring harnesses.

Hot-melt adhesives have a wide range of applications. The packaging industry accounts for more than 50% of the hot-melt adhesives application market. These packaging materials include pleated cardboard boxes, corrugated boxes, cans of laminated materials, tapes, and other laminated film materials. Woven textiles include sanitary napkins, paper diapers, ready-to-fit garments, and seam stitching. Woven products include garments, seams, tapes, carpet backing. Office supplies include tape, documents, self-adhesive labels, envelopes, and folders. The combination of parts includes soda, electronics, book packaging, furniture, shoes, handicrafts, as well as carpentry and plywood.

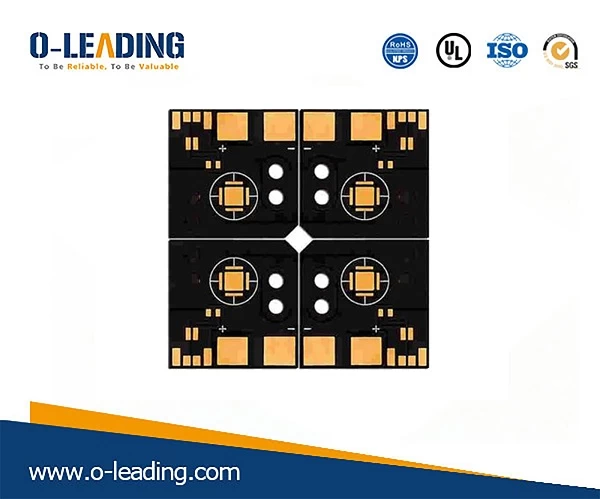

HEAVY COPPER BOARD manufacturer china

Because hot melt adhesive has a wide range of applications, its non-pollution and pollution-free characteristics make it a great advantage in replacing solvent-based adhesives. But because of its limitations. Special attention should also be paid to the application. Here are a few items.

1.Viscosity

Melt viscosity is an important indicator of workability. Because hot melt adhesives must be used with the aid of a heater, that is, a coating machine. Generally speaking, different industries, different applications, different physical properties, different coating machines, and coating methods determine their melt viscosity. It should be noted here that the use of the same purpose, but due to different manufacturers of coating machines and methods, the viscosity of hot melt adhesives are also different.

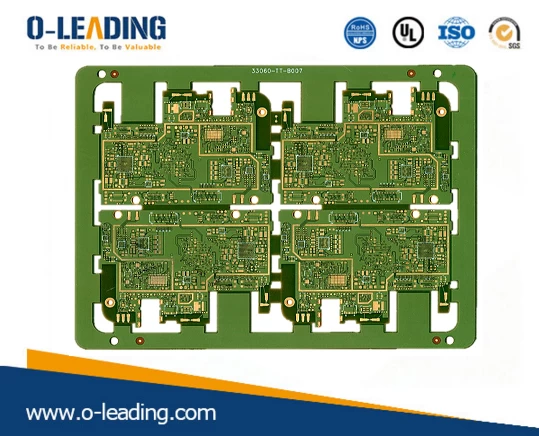

Engine Power Module manufacturer china

2. Curing time, opening time

The use of hot melt adhesives uses heat as a medium, and the colloids are cooled after completion. Therefore, it is necessary to pay attention to the control of the operating time during use.

· Setting time : refers to the best short time after coating can be formed.

· Open time: The maximum time allowed after coating to compression.

3. Temperature resistance

EVA hot-melt adhesives are limited by their physical properties, so their heat resistance is between 40 ° C and 65 ° C under constant temperature conditions. The main point is that the melting point of EVA is generally between 40 ° C and 70 ° C, and TPR itself The heat resistance is better, but it is often necessary to add a plasticizer to reduce its heat resistance.

4. Adherence

Talking about adhesiveness, the main focus is on the material being coated. According to the general classification, there are metal, plastic, paper, wood, etc. or according to the bonding conditions required by customers. Avoid problems after the event and save service time.