Basic rules for PCB component layout

PCB is also called Printed Circuit Board (Printed Circuit Board), which can realize the circuit connection and function realization between electronic components, and it is also an important part of power circuit design.

1. Layout according to circuit modules, related circuits that achieve the same function are called a module, and the components in the circuit module should adopt the principle of nearest concentration, while digital circuits and analog circuits are separated;

2. Positioning holes, standard holes and other non-installation holes should not be mounted within 1.27mm around the element, device, screws and other mounting holes around 3.5mm (for M2.5), 4mm (for M3) components should not be mounted;

3. Avoid laying vias under components such as resistances, inductors (plug-ins), electrolytic capacitors, etc., to avoid short-circuiting the vias with the component housing after wave soldering;

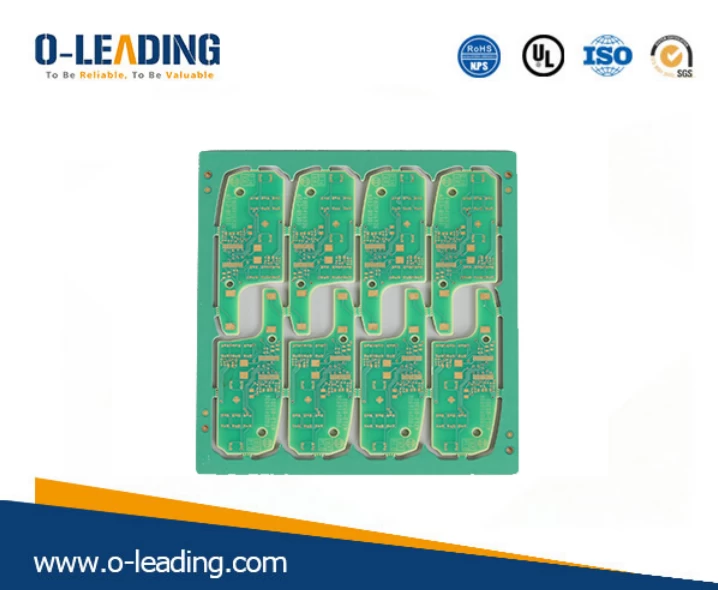

Halogen free pcb factory china

4. The distance from the outside of the component to the edge of the board is 5mm;

5. The distance between the outside of the mounting component pad and the outside of the adjacent insertion component is greater than 2mm;

6. Metal housing components and metal parts (shielding boxes, etc.) must not collide with other components, and should not be close to printed wires and pads. The distance between them should be greater than 2mm. The size of the positioning hole, fastener installation hole, oval hole and other square holes in the board is greater than 3mm from the side of the board;

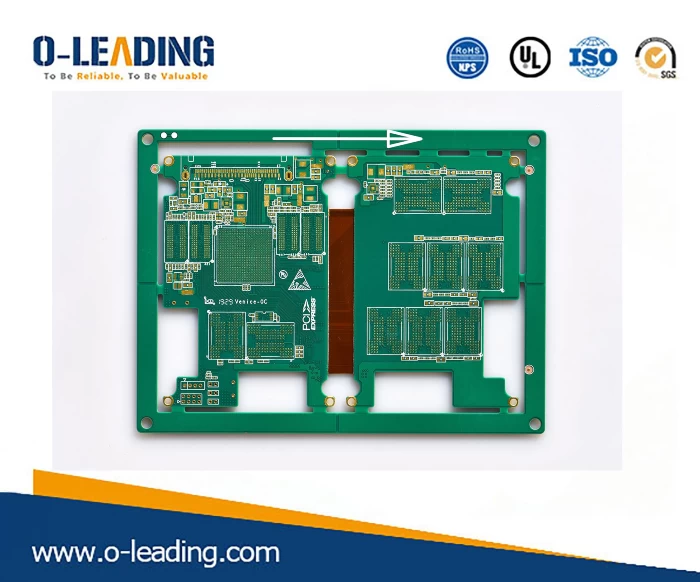

low price Thick Copper PCB

7. The heating element should not be close to the wires and heat-sensitive components; the high-heat components should be evenly distributed;

8. The power sockets should be arranged around the printed board as much as possible, and the bus bar terminals connected to the power sockets should be arranged on the same side. Special care should be taken not to place power sockets and other soldered connectors between the connectors, in order to facilitate the welding of these sockets, connectors, and the design and tying of power cables. The spacing between power sockets and soldered connectors should be considered to facilitate the insertion and removal of power plugs;

9. Arrangement of other components:

All IC components are aligned on one side, with polar components clearly marked on the same printed circuit board. The polar labels on the same printed board should not be more than two directions. When two directions appear, the two directions are perpendicular to each other;

High Tg PCB manufacturer china

10, board wiring should be properly dense, when the density difference is too large, it should be filled with mesh copper foil, grid greater than 8mil (or 0.2mm);

11. There must be no through holes in the patch pads, so as to avoid the soldering of components due to the loss of solder paste. Important signal cables are not allowed to pass between the feet of the socket;

12.Single side of the patch is aligned, the character direction is the same, and the packaging direction is the same;

13. Polarized devices should be as consistent as possible with the polarity marked on the same board.